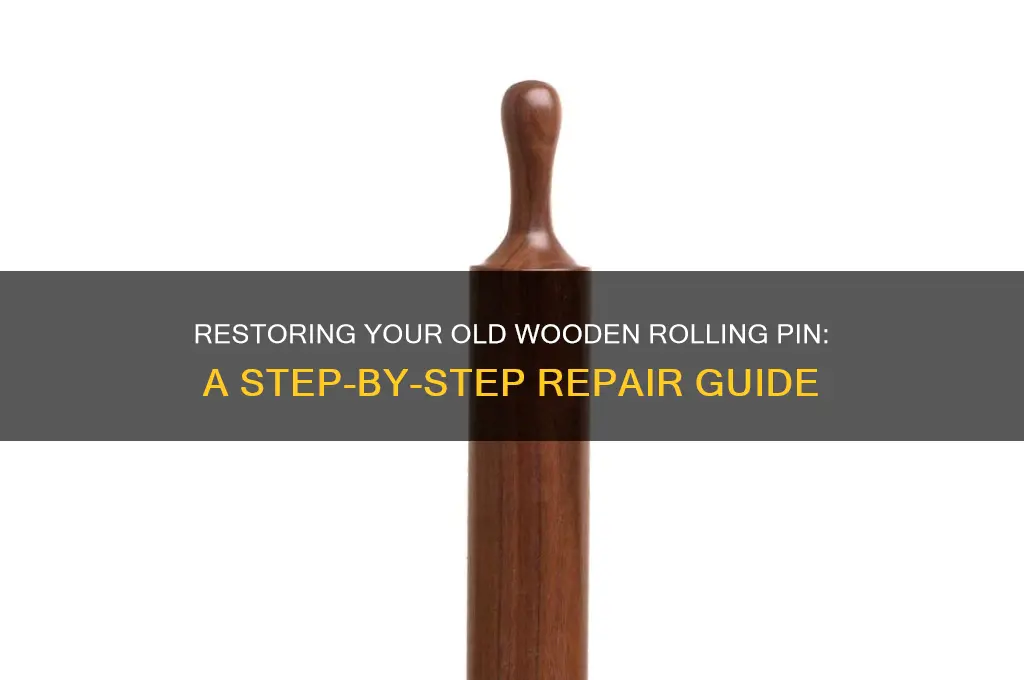

Repairing an old wooden rolling pin can be a rewarding project that not only restores a cherished kitchen tool but also preserves its sentimental value. Over time, wooden rolling pins may develop cracks, splinters, or lose their smooth finish due to wear and tear. To begin the repair process, start by cleaning the rolling pin thoroughly with mild soap and warm water, ensuring it’s completely dry before proceeding. For minor cracks or splits, apply a food-safe wood glue to the affected area, clamping it gently until the glue sets. Sand the surface with fine-grit sandpaper to remove any rough spots or splinters, then finish by conditioning the wood with a food-grade mineral oil or beeswax to restore its natural luster and protect it from moisture. With care and attention, your wooden rolling pin can be brought back to life, ready for many more years of use.

| Characteristics | Values |

|---|---|

| Material | Wood (type may vary, e.g., beech, maple, oak) |

| Common Issues | Cracks, splits, warping, loose handles, rough surface |

| Tools Needed | Sandpaper (various grits), wood glue, clamps, wood filler, varnish/oil, rags, screwdriver (if handles are detachable) |

| Repair Steps | 1. Clean the rolling pin thoroughly. 2. Sand the surface to smooth out rough areas. 3. Fill cracks or splits with wood filler or glue. 4. Reattach loose handles with glue or screws. 5. Sand again for a smooth finish. 6. Apply food-safe oil or varnish to protect the wood. |

| Drying Time | 24-48 hours for glue/filler; follow product instructions for oil/varnish |

| Maintenance | Regularly oil the rolling pin to prevent drying and cracking. Hand wash only; avoid soaking in water. |

| Safety Tips | Ensure all materials used (glue, oil, varnish) are food-safe. Test the rolling pin for splinters or rough spots before use. |

| Cost | Low (depends on materials needed; often under $20) |

| Difficulty Level | Beginner to intermediate, depending on the extent of damage |

| Time Required | 1-2 hours (excluding drying time) |

Explore related products

What You'll Learn

- Inspect for Damage: Check for cracks, splinters, or warping in the wooden rolling pin

- Clean Thoroughly: Wash with mild soap, dry completely, and remove any residue

- Sand Smoothly: Use fine-grit sandpaper to smooth rough surfaces and edges

- Apply Oil: Coat with food-safe mineral oil to restore moisture and protect wood

- Repair Cracks: Fill gaps with wood glue or epoxy, clamp, and let dry

Inspect for Damage: Check for cracks, splinters, or warping in the wooden rolling pin

Before attempting any repair, a thorough inspection of your wooden rolling pin is crucial. This initial assessment will guide your restoration process, ensuring you address the specific issues affecting your tool. Begin by examining the surface for any visible cracks, which can range from fine hairline fractures to more significant splits. These imperfections not only compromise the pin's structural integrity but can also harbor bacteria, making it unsafe for food preparation. Run your fingers along the length of the pin, feeling for any raised edges or splinters that might have formed due to the wood's natural tendency to split over time.

The presence of splinters is a common issue with aged wooden utensils. These sharp fragments can easily break off, posing a risk of injury and contaminating your dough. To identify them, visually scan the entire surface, paying close attention to areas where the wood grain is more pronounced. A magnifying glass can be a useful tool for detecting smaller splinters. Once identified, mark these areas with a soft pencil to ensure you address them during the repair process.

Warping is another critical aspect to inspect. Over time, wood can distort due to changes in humidity and temperature, causing the rolling pin to lose its cylindrical shape. This deformation can result in uneven dough thickness, defeating the purpose of using a rolling pin. To check for warping, place the pin on a flat surface and observe if it rocks or sits unevenly. You can also use a straightedge or a ruler to measure the pin's diameter at various points, comparing the readings to identify any deviations from its original form.

The inspection process is a delicate balance between identifying issues and understanding the wood's natural characteristics. Some minor imperfections might not require immediate attention, especially if they are purely cosmetic and do not affect functionality. However, it's essential to differentiate between these and more severe problems. For instance, a small crack that runs along the wood grain might be less concerning than a deep cross-grain crack, which could indicate a more significant structural weakness.

In summary, a detailed inspection is the foundation of a successful repair. By carefully examining your rolling pin for cracks, splinters, and warping, you can tailor your restoration approach, ensuring the tool's longevity and safety for culinary use. This initial step is both an art and a science, requiring a keen eye and an understanding of wood's unique properties.

Vintage Wooden Christmas Angel Ornaments: Are They Valuable Collectibles?

You may want to see also

Explore related products

Clean Thoroughly: Wash with mild soap, dry completely, and remove any residue

Wooden rolling pins, often cherished for their rustic charm and functionality, can accumulate grime, oil, and residue over time, especially if they’ve been stored improperly or used frequently. Before any repair or restoration begins, thorough cleaning is essential. Start by washing the rolling pin with a mild dish soap and warm water, using a soft-bristled brush or sponge to gently scrub away surface dirt. Avoid soaking the wood, as prolonged exposure to water can cause warping or cracking. Focus on crevices and engraved areas where debris tends to collect. This initial step not only prepares the surface for repair but also ensures that any treatments or finishes adhere properly.

Drying the rolling pin completely is just as critical as the cleaning itself. Moisture trapped in the wood can lead to mold, mildew, or structural damage. After washing, pat the rolling pin dry with a clean towel and let it air-dry in a well-ventilated area for at least 24 hours. For added assurance, consider using a hairdryer on a low heat setting, keeping it at a safe distance to avoid overheating the wood. Rotate the rolling pin periodically to ensure all surfaces, including the handles and barrel, are thoroughly dried. Incomplete drying can undermine subsequent repair efforts, so patience is key.

Residue removal is the final step in this cleaning process and should not be overlooked. Even after washing and drying, stubborn residues like old food particles, wax, or varnish may remain. For sticky residues, a paste of baking soda and water can be applied, left for 10–15 minutes, and then scrubbed off gently. For tougher residues, a fine-grit sandpaper (220-grit or higher) can be used to carefully sand the affected areas, taking care not to damage the wood’s surface. Always sand in the direction of the grain to maintain the rolling pin’s integrity. This meticulous approach ensures the wood is pristine and ready for the next phase of repair or restoration.

The importance of this cleaning process cannot be overstated, as it directly impacts the longevity and functionality of the rolling pin. Skipping or rushing through these steps can lead to unsatisfactory results, such as finishes that peel or wood that deteriorates prematurely. Think of this cleaning phase as the foundation of your repair project—a clean, dry, residue-free surface is essential for any treatments, such as oiling, waxing, or refinishing, to take hold effectively. By investing time in this initial stage, you’re not just cleaning the rolling pin; you’re preserving its life and ensuring it remains a reliable kitchen tool for years to come.

Bigleaf Hydrangeas: Blooming Secrets of Old Wood Explained

You may want to see also

Explore related products

Sand Smoothly: Use fine-grit sandpaper to smooth rough surfaces and edges

Fine-grit sandpaper is your first line of defense against the wear and tear that time inflicts on wooden rolling pins. Over years of use, the surface can become rough, splintered, or marred by cracks, making it less effective for rolling dough and potentially unsafe. Starting with a grit between 120 and 180 allows you to remove surface imperfections without stripping away too much of the wood’s natural texture. This initial pass prepares the surface for finer sanding, ensuring a smoother, more polished finish.

The technique matters as much as the tool. Always sand in the direction of the wood grain to avoid creating scratches or further damage. Use light, even pressure, and work systematically across the entire surface, paying extra attention to edges and handles where roughness is most noticeable. For curved areas, wrap the sandpaper around a block or use your fingers to conform to the shape, maintaining consistent contact. This methodical approach ensures uniformity and prevents over-sanding in any one spot.

Once the coarse grit has done its job, progress to a finer grit—220 or higher—to refine the surface further. This step is where the rolling pin begins to regain its original smoothness. Fine-grit sandpaper removes the scratches left by the coarser grit, creating a silky finish that’s both functional and aesthetically pleasing. After sanding, wipe the surface with a damp cloth to remove dust and inspect your work. If any rough spots remain, repeat the process until the entire pin is uniformly smooth.

A word of caution: while sanding is essential, it’s easy to overdo it. Excessive sanding can thin the wood, weaken structural integrity, or alter the pin’s shape. Always prioritize preservation over perfection, especially with antique or sentimental pieces. After sanding, consider applying a food-safe mineral oil or beeswax to condition the wood, enhance its appearance, and protect it from future damage. This final step not only extends the rolling pin’s life but also ensures it remains safe for culinary use.

Exploring the Size and History of Vintage Wooden Barrels

You may want to see also

Explore related products

Apply Oil: Coat with food-safe mineral oil to restore moisture and protect wood

Wooden rolling pins, especially older ones, can dry out over time, leading to cracks, splinters, or a rough surface that affects their functionality. Applying food-safe mineral oil is a simple yet effective way to restore moisture, protect the wood, and extend the life of your rolling pin. This process not only enhances the wood’s natural beauty but also ensures the surface remains smooth and safe for food preparation. Mineral oil is ideal because it’s non-toxic, odorless, and won’t go rancid like some other oils, making it a trusted choice for kitchenware.

To begin, clean your rolling pin thoroughly with mild soap and warm water, ensuring all food residue and dirt are removed. Dry it completely with a clean towel and allow it to air-dry for at least an hour to ensure no moisture remains. Once dry, pour a small amount of food-safe mineral oil onto a clean cloth or paper towel—start with about a teaspoon, as a little goes a long way. Rub the oil onto the rolling pin in a circular motion, covering the entire surface, including the handles and any crevices. Focus on areas that appear particularly dry or cracked, as these will absorb the oil more readily.

The frequency of oiling depends on how often you use the rolling pin and the condition of the wood. For heavily used or older rolling pins, apply oil once a month to maintain moisture and protection. For lightly used or newer pins, every 2–3 months should suffice. After applying the oil, let the rolling pin sit for at least 30 minutes to allow the wood to absorb it fully. Wipe off any excess oil with a clean cloth to prevent a greasy residue, which could transfer to food during use.

One practical tip is to pair this maintenance routine with a visual inspection of your rolling pin. Look for signs of wear, such as deepening cracks or loose handles, which may require additional repairs. Regular oiling not only preserves the wood but also gives you an opportunity to catch potential issues early. Over time, this simple care routine will keep your rolling pin in excellent condition, ensuring it remains a reliable tool in your kitchen for years to come.

Stuart Woods' Wife: Unveiling Her Age and Their Love Story

You may want to see also

Explore related products

Repair Cracks: Fill gaps with wood glue or epoxy, clamp, and let dry

Cracks in a wooden rolling pin aren't just unsightly—they can compromise its functionality and longevity. Repairing these fissures with wood glue or epoxy is a straightforward yet effective method to restore both form and function. The key lies in choosing the right adhesive and applying it meticulously to ensure a strong, seamless bond.

Steps to Repair Cracks:

Begin by cleaning the rolling pin thoroughly, removing any debris or loose wood fibers from the cracked area. For fine cracks, wood glue is ideal due to its flexibility and compatibility with wood. Apply a thin, even layer of glue into the crack, using a toothpick or small brush to ensure it penetrates deeply. For wider gaps, epoxy resin is a better choice, as it hardens into a rigid, durable filler. Mix the epoxy according to the manufacturer’s instructions, then press it firmly into the crack, slightly overfilling to account for shrinkage during curing.

Cautions and Tips:

Avoid using excessive glue or epoxy, as this can lead to uneven surfaces or difficulty sanding later. Clamping is crucial to hold the crack closed while the adhesive dries. Use a clamp or wrap the rolling pin tightly with rubber bands, ensuring even pressure along the crack. Allow the adhesive to cure fully—typically 24 hours for wood glue and 48 hours for epoxy—before handling the rolling pin.

Practical Takeaway:

This repair method not only extends the life of your rolling pin but also preserves its natural feel and texture. With proper care, the repaired area can be just as strong as the original wood, allowing you to continue using the rolling pin for years to come. Whether you’re a professional baker or a home cook, this simple fix ensures your trusty tool remains reliable and functional.

Reinforcing My Old Wood Foundation: Techniques, Materials, and Expert Tips

You may want to see also

Frequently asked questions

Gently scrub the rolling pin with warm, soapy water using a soft brush or sponge. Avoid soaking it, as prolonged exposure to water can cause the wood to warp or crack. Dry it thoroughly with a clean towel and let it air dry completely before proceeding with repairs.

Apply a food-safe wood glue into the crack or split, ensuring it penetrates deeply. Clamp the rolling pin lightly or use rubber bands to hold the pieces together while the glue dries. Sand the repaired area lightly once dry to ensure a smooth finish.

Sand the rolling pin with fine-grit sandpaper (220-grit or higher) to remove any rough spots or old finish. Apply a food-safe mineral oil or beeswax to condition and protect the wood. Rub it in thoroughly, let it absorb, and buff off any excess for a smooth, natural finish.