Reinforcing an old wood foundation is a critical process that involves assessing the structural integrity of the existing wood, identifying areas of weakness or damage, and implementing targeted solutions to enhance stability and longevity. Common methods include sistering new lumber alongside deteriorated sections, adding steel brackets or joist hangers for additional support, and applying epoxy or wood hardeners to repair rot or decay. In some cases, moisture barriers or waterproofing treatments are applied to prevent future damage, while proper ventilation and drainage systems are installed to mitigate environmental stressors. This comprehensive approach ensures the foundation remains robust and capable of supporting the structure above, blending traditional craftsmanship with modern materials and techniques.

Explore related products

What You'll Learn

- Inspect for Damage: Check wood for rot, cracks, or pest infestations before reinforcing

- Clean and Prep: Remove debris, dirt, and old sealant to ensure proper adhesion

- Add Support Beams: Install new beams or posts to distribute weight and stabilize the foundation

- Apply Waterproofing: Use sealants or coatings to protect wood from moisture and decay

- Reinforce with Brackets: Attach metal brackets or plates to strengthen joints and connections

Inspect for Damage: Check wood for rot, cracks, or pest infestations before reinforcing

Before reinforcing an old wood foundation, a meticulous inspection is crucial. Start by examining the wood for signs of rot, which often manifests as a soft, spongy texture or discoloration. Use a screwdriver to gently probe the surface; if it sinks in easily, the wood is compromised. Rot typically occurs in areas with prolonged moisture exposure, such as near leaky pipes or poorly drained soil. Addressing the source of moisture is essential before proceeding with reinforcement to prevent recurring damage.

Cracks in the wood are another red flag, especially if they are wide or extend deep into the structure. Measure cracks wider than 1/4 inch, as these can weaken the foundation’s integrity. Hairline cracks may be less concerning but should still be monitored. For deeper cracks, consider using epoxy fillers designed for structural wood repair. However, if the cracks are extensive or accompanied by sagging, consult a structural engineer to assess whether reinforcement alone is sufficient.

Pest infestations, particularly termites and carpenter ants, can silently undermine a wood foundation. Look for telltale signs such as small holes, sawdust-like frass, or hollow-sounding wood when tapped. Termite damage often appears as grooves or tunnels within the wood, while carpenter ants leave smoother excavations. If pests are detected, treat the infestation professionally before reinforcing. Use borate-based wood preservatives to deter future infestations, applying them according to manufacturer instructions for optimal protection.

A systematic approach to inspection ensures no damage is overlooked. Begin by dividing the foundation into sections and document findings with notes or photos. Pay special attention to joints, corners, and areas in contact with soil or masonry. For older homes, consider hiring a certified inspector with experience in historic structures, as they may identify issues less obvious to the untrained eye. This thorough assessment not only guides the reinforcement process but also prevents costly mistakes down the line.

Finally, prioritize safety and practicality during inspection. Wear protective gear, including gloves and a mask, when handling old wood that may contain mold or chemicals. Use proper lighting to avoid missing subtle signs of damage. If the foundation is in a crawl space or basement, ensure adequate ventilation and stability before entering. By addressing rot, cracks, and pests proactively, you lay the groundwork for a successful and lasting reinforcement of your old wood foundation.

Megan Woods' Age: Unveiling the Singer's Timeless Journey and Birth Year

You may want to see also

Explore related products

Clean and Prep: Remove debris, dirt, and old sealant to ensure proper adhesion

Before any reinforcement can take place, the foundation must be stripped of all contaminants that could compromise the bond between the wood and the new materials. This step is often overlooked, but it’s the linchpin of a successful repair. Debris, dirt, and old sealant act as barriers, preventing adhesives, epoxies, or new wood treatments from adhering properly. Even microscopic particles can weaken the structural integrity over time. Think of it as preparing a canvas for a masterpiece—the surface must be pristine for the art to last.

The process begins with a thorough inspection. Use a bright light and magnifying glass to identify cracks, crevices, or hidden pockets of dirt. Hand tools like wire brushes, scrapers, and chisels are ideal for removing loose debris and flaking wood. For stubborn grime, a pressure washer set to a low-to-medium setting (1,500–2,000 PSI) can be effective, but caution is key—excessive force can damage the wood fibers. Follow this with a stiff-bristle brush and a mixture of mild detergent and water to dissolve oils or stains. Rinse thoroughly and allow the wood to dry completely, as moisture can trap air pockets beneath the surface.

Old sealant is perhaps the most insidious culprit. Its remnants can create a slippery, non-porous layer that repels new treatments. Chemical strippers (citrus-based or solvent-based) are effective but require careful application. Apply a thin, even coat, let it sit for 15–30 minutes, then scrape off with a plastic putty knife to avoid scratching the wood. For hard-to-reach areas, a rotary tool with a wire brush attachment can be invaluable. Always wear gloves, goggles, and a respirator when working with chemicals, and ensure proper ventilation.

Once cleaned, the wood should feel rough to the touch—a sign its pores are open and ready to bond. Test adhesion by applying a small amount of epoxy to a discreet area. If it sets firmly within 24 hours, the surface is prepped correctly. If not, repeat the cleaning process. This step, though time-consuming, is non-negotiable. Skipping it risks costly failures down the line, such as delamination or uneven settling. In the world of foundation repair, patience in preparation pays dividends in longevity.

Finally, consider the environmental factors. Humidity, temperature, and wood age influence drying times and adhesion. For older foundations (50+ years), the wood may be more brittle, requiring gentler cleaning methods. In humid climates, use a dehumidifier or space heater to expedite drying. By treating this phase as a science—methodical, precise, and tailored to the material—you ensure the foundation is not just clean, but primed for reinforcement that will stand the test of time.

Rambling Roses: Blooming on Old Wood or New Growth?

You may want to see also

Explore related products

$36.58 $49

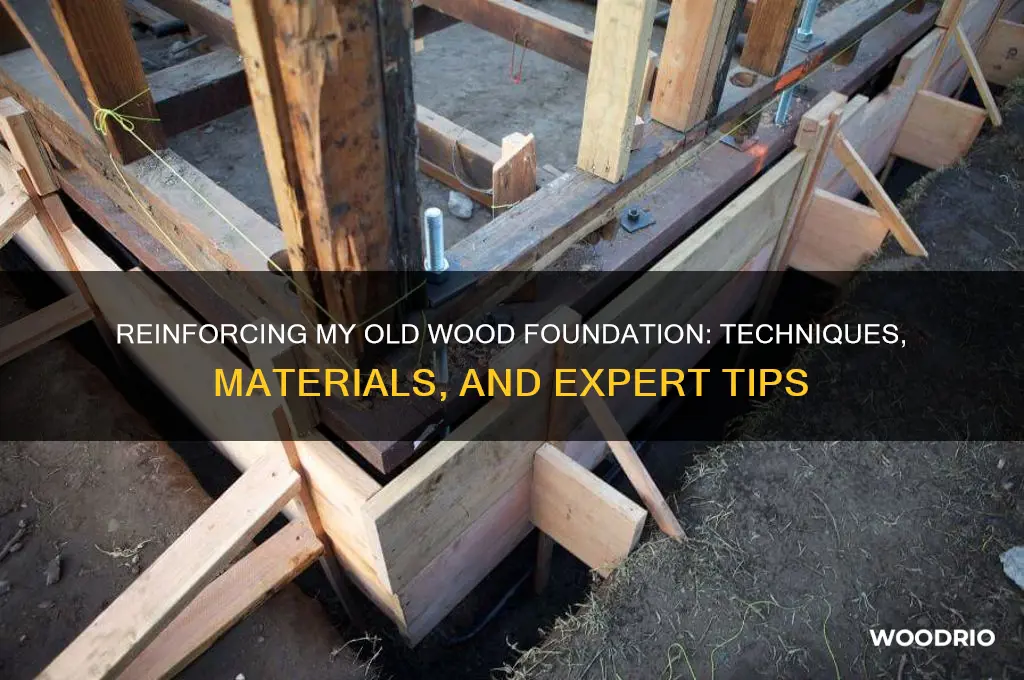

Add Support Beams: Install new beams or posts to distribute weight and stabilize the foundation

One of the most effective ways to reinforce an old wood foundation is by adding support beams or posts. Over time, wooden foundations can sag or weaken due to soil movement, moisture, or the weight of the structure above. Installing new beams redistributes the load, preventing further settling and stabilizing the foundation. This method is particularly useful when the original foundation lacks sufficient structural integrity or when repairs alone cannot address the underlying issues.

To begin, assess the foundation’s condition by identifying areas of weakness or visible sagging. Use a level to check for uneven floors or walls, as these are telltale signs of foundation distress. Once problem areas are pinpointed, determine the optimal placement for new beams. Typically, beams are installed perpendicular to the existing joists or along load-bearing walls. For maximum effectiveness, ensure the beams rest on solid footings or piers that extend below the frost line to prevent shifting.

The installation process involves careful planning and precision. Start by measuring and cutting the beams to the required length, using pressure-treated lumber or engineered wood products for durability. Position the beams directly beneath the floor joists or walls, securing them with galvanized metal connectors to ensure a strong bond. If the foundation is severely compromised, consider adding temporary jacks to lift the structure slightly before placing the beams. This step alleviates pressure on the new supports during installation.

While adding support beams is a proven method, it’s not without challenges. Overloading the beams can lead to further damage, so consult a structural engineer to calculate the appropriate size and spacing. Additionally, improper installation can exacerbate existing issues, making professional guidance invaluable. Despite these considerations, the long-term benefits of added stability and extended foundation life make this approach a worthwhile investment for older homes.

In comparison to other reinforcement methods, such as sistering joists or adding steel brackets, installing support beams offers a more comprehensive solution by addressing the foundation’s overall load distribution. While sistering involves strengthening individual joists, beams provide a systemic fix that can prevent future problems. Similarly, steel brackets are often used for localized repairs, whereas beams offer a holistic approach to stabilization. For homeowners seeking a robust, long-lasting solution, adding support beams is a strategic choice that combines practicality with structural integrity.

Does Wood Decay in Aging Homes? Understanding Old House Maintenance

You may want to see also

Explore related products

Apply Waterproofing: Use sealants or coatings to protect wood from moisture and decay

Moisture is the arch-nemesis of wood foundations, accelerating rot, attracting pests, and compromising structural integrity. Waterproofing acts as a shield, repelling water and preventing its destructive effects. Sealants and coatings form a protective barrier, sealing pores and cracks to deny moisture entry. This simple yet effective measure can significantly extend the lifespan of an old wood foundation.

Opting for the right waterproofing product is crucial. Silicone-based sealants offer superior flexibility, ideal for areas prone to movement, while acrylic coatings provide a breathable barrier, allowing moisture vapor to escape while repelling liquid water. Consider the foundation's condition, climate, and desired durability when making your choice. Application methods vary, but generally involve thorough cleaning and drying of the wood surface, followed by brush, roller, or spray application of the chosen product. Multiple coats may be necessary for optimal protection.

Imagine a weathered pier, its wooden pilings constantly battered by waves and tides. Without waterproofing, these pilings would succumb to rot within years. However, a regular application of marine-grade sealant creates a hydrophobic barrier, repelling water and allowing the pier to stand strong against the relentless assault of the sea. This real-world example highlights the transformative power of waterproofing, demonstrating its ability to protect wood even in the harshest environments.

While waterproofing is essential, it's not a standalone solution. Proper drainage around the foundation is equally crucial to prevent water pooling and seepage. Additionally, regular inspections and reapplication of waterproofing every few years ensure continued protection. By combining waterproofing with other maintenance practices, you can effectively safeguard your old wood foundation for generations to come.

Natalie Wood's Age in Gypsy: A Surprising Revelation

You may want to see also

Explore related products

$15.86 $16.8

Reinforce with Brackets: Attach metal brackets or plates to strengthen joints and connections

Metal brackets and plates offer a straightforward yet effective solution for reinforcing weak joints and connections in old wood foundations. These components act as external skeletons, redistributing stress and preventing further deterioration. Typically made from galvanized steel or aluminum to resist corrosion, they are secured using heavy-duty screws or bolts designed for structural applications. For maximum effectiveness, brackets should be installed at critical points such as beam-to-post connections, sill plate joints, or areas showing signs of cracking or warping. This method is particularly useful when the original wood has degraded but remains structurally viable with additional support.

The process begins with assessing the foundation to identify vulnerable joints. Measure the dimensions of the wood members to ensure the brackets fit snugly, as gaps can compromise their load-bearing capacity. Pre-drilling holes is essential to prevent wood splitting, especially in aged timber. For example, a 4-inch by 4-inch bracket might require ½-inch diameter bolts spaced every 6 inches along the joint. Always use a torque wrench to tighten fasteners to the manufacturer’s specifications, typically 75–100 foot-pounds for structural screws in hardwood. Applying a bead of construction adhesive between the bracket and wood can further enhance stability.

While brackets are durable, their long-term effectiveness depends on proper installation and environmental conditions. In humid climates, ensure all metal components are coated with a rust-inhibiting primer, even if they are galvanized. Avoid overloading the reinforced joints; brackets are meant to stabilize, not to compensate for severe structural failure. Regular inspections every 1–2 years can catch early signs of bracket loosening or corrosion, allowing for timely maintenance. For foundations in flood-prone areas, consider elevating brackets or using marine-grade stainless steel for added resilience.

Comparing this method to alternatives like sistering or epoxy injection, bracket reinforcement stands out for its simplicity and cost-effectiveness. Sistering involves adding new wood alongside old, which can be labor-intensive and may not address joint weaknesses directly. Epoxy injection, while effective for cracks, does little to strengthen connections. Brackets, on the other hand, provide immediate mechanical support and can be installed with basic tools. However, they are most suitable for localized issues rather than widespread foundation damage, making them a targeted rather than comprehensive solution.

In practice, combining brackets with other reinforcement techniques can yield the best results. For instance, installing brackets at critical joints while sistering beams can address both connection and member weaknesses. Always consult a structural engineer when dealing with load-bearing elements, as improper reinforcement can lead to catastrophic failure. With careful planning and execution, metal brackets can extend the life of an old wood foundation by decades, preserving both safety and historical integrity.

Lost and Found: A Toddler's Miraculous Survival in the Wild

You may want to see also

Frequently asked questions

Common methods include sistering (attaching new lumber alongside old), adding steel brackets or joist hangers, installing foundation piers, and applying epoxy or wood hardeners to damaged areas.

Signs include sagging floors, visible cracks in the wood, rot or termite damage, and noticeable shifting or settling of the structure.

Minor repairs like sistering or applying wood hardeners can be DIY, but major structural issues like foundation piers or extensive rot repair typically require a professional contractor.

Pressure-treated lumber, steel brackets, epoxy resins, and concrete piers are commonly used for reinforcement, depending on the specific issues and structural needs.