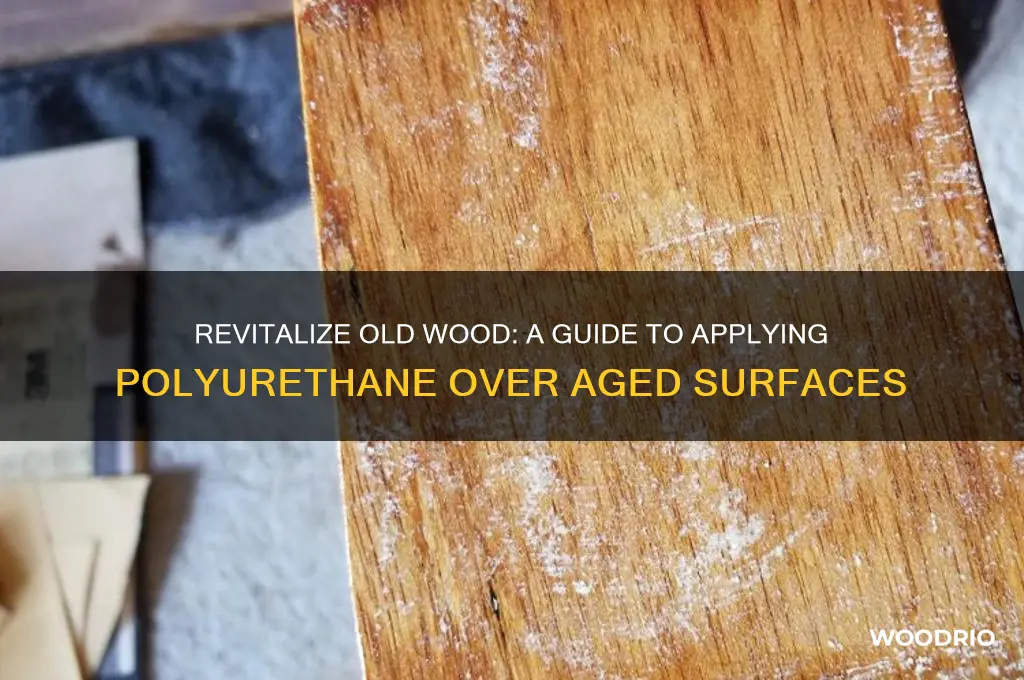

Applying polyurethane over old wood is a great way to restore and protect its natural beauty while adding durability and a fresh finish. Before starting, it’s essential to assess the condition of the wood, ensuring it’s clean, smooth, and free of old finishes or stains that may interfere with adhesion. Begin by sanding the surface to remove any rough spots, dirt, or existing coatings, using progressively finer grits for a smooth base. Clean the wood thoroughly to remove dust and debris, and consider applying a wood conditioner if the wood is bare to ensure even absorption. Once prepared, apply the polyurethane in thin, even coats using a brush, roller, or sprayer, allowing each layer to dry completely before sanding lightly between coats for a smooth finish. This process not only enhances the wood’s appearance but also provides long-lasting protection against wear, moisture, and damage.

| Characteristics | Values |

|---|---|

| Surface Preparation | Clean thoroughly, sand to roughen surface, remove dust and grease |

| Sanding Grit | 120-150 grit for initial sanding, 220 grit for final smoothing |

| Cleaning Agents | Mineral spirits, TSP (trisodium phosphate), or wood cleaner |

| Polyurethane Type | Oil-based or water-based (choose based on desired finish and odor tolerance) |

| Application Tools | High-quality brush, foam brush, or sprayer |

| Application Technique | Thin, even coats, following the wood grain |

| Drying Time | 2-4 hours between coats (varies by product and humidity) |

| Number of Coats | 2-3 coats recommended for durability |

| Light Sanding Between Coats | 220-320 grit to ensure smooth finish |

| Cure Time | 24-48 hours before light use, 72 hours for full cure |

| Maintenance | Reapply polyurethane every 3-5 years or as needed |

| Common Issues | Bubbling, streaking, or uneven finish (avoid over-brushing or applying thick coats) |

| Safety Precautions | Work in a well-ventilated area, wear gloves and a mask |

| Compatibility | Test on a small area first to ensure compatibility with existing finish |

| Environmental Factors | Avoid applying in high humidity or extreme temperatures |

Explore related products

What You'll Learn

- Surface Preparation: Clean, sand, and remove old finish for proper adhesion

- Choosing Polyurethane: Select oil- or water-based type based on wood and desired look

- Application Tools: Use brushes, rollers, or sprayers for even coverage

- Coat Application: Apply thin, multiple coats, sanding lightly between layers

- Drying and Curing: Allow ample drying time and avoid use until fully cured

Surface Preparation: Clean, sand, and remove old finish for proper adhesion

Before applying polyurethane over old wood, the surface must be meticulously prepared to ensure adhesion and longevity. Neglecting this step can lead to peeling, bubbling, or an uneven finish. The process begins with a thorough cleaning to remove dirt, grease, and grime that accumulate over time. Use a mild detergent mixed with warm water and a soft-bristle brush to scrub the surface. For stubborn stains or wax buildup, a solvent like mineral spirits or trisodium phosphate (TSP) solution can be more effective. Rinse the wood thoroughly and allow it to dry completely—at least 24 hours—before proceeding.

Sanding is the next critical step, as it creates a rough surface for the polyurethane to grip. Start with a coarse-grit sandpaper (80–120 grit) to remove the old finish and smooth out imperfections. Work in the direction of the wood grain to avoid scratches. Once the old finish is gone, switch to a finer grit (150–220 grit) to create a uniform surface. Pay special attention to edges, corners, and detailed areas, as these spots often retain more of the old finish. After sanding, remove all dust with a tack cloth or a vacuum with a brush attachment. Residual dust can interfere with adhesion, so this step cannot be rushed.

Removing the old finish entirely is essential, particularly if it’s flaking or uneven. Chemical strippers are a reliable option for this task, but they require caution. Apply the stripper generously with a brush, let it sit according to the manufacturer’s instructions (typically 15–30 minutes), and then scrape off the softened finish with a plastic scraper. Avoid metal scrapers, as they can damage the wood. For smaller projects or delicate surfaces, a heat gun can be used to soften the finish, followed by careful scraping. Always work in a well-ventilated area and wear protective gear, including gloves and a respirator, when using chemicals or heat.

The final step in surface preparation is assessing the wood’s condition. If the wood is dry or porous, apply a wood conditioner to ensure even absorption of the polyurethane. This is particularly important for softwoods like pine or cedar. For older wood, inspect for cracks, splits, or rot. Repair these issues before proceeding, using wood filler or epoxy for structural integrity. Once the surface is clean, smooth, and free of old finish, it’s ready for polyurethane. Proper preparation may seem time-consuming, but it’s the foundation for a durable and professional-looking finish.

Guava Fruit Production: Understanding Old Wood's Role in Yield

You may want to see also

Explore related products

Choosing Polyurethane: Select oil- or water-based type based on wood and desired look

Polyurethane selection hinges on the wood’s condition and your aesthetic goals. Oil-based polyurethane penetrates deeper, enhancing the wood’s natural grain and providing a richer, amber hue. This makes it ideal for older wood with character, such as antique furniture or reclaimed flooring, where you want to accentuate warmth and depth. Water-based polyurethane, on the other hand, dries clear and maintains the wood’s original color, making it better suited for lighter woods or projects where you prefer a more natural, unaltered appearance.

Consider the wood’s age and porosity when choosing. Older wood, especially if it’s dry or weathered, absorbs oil-based polyurethane more readily, which can help revive its texture and luster. However, if the wood is already dark or you’re working with a piece that has a lighter, modern finish, water-based polyurethane avoids adding unwanted yellowing. Test a small, inconspicuous area first to ensure the result aligns with your vision.

Application techniques differ slightly between the two types. Oil-based polyurethane requires more ventilation due to its strong fumes and longer drying time—typically 8–24 hours between coats. Water-based polyurethane dries faster, often within 2–4 hours, and has lower VOC emissions, making it a safer option for indoor projects. Both types require thin, even coats applied with a high-quality brush or foam applicator to avoid streaks or bubbles.

Durability is another factor. Oil-based polyurethane is generally more resistant to scratches and wear, making it a better choice for high-traffic areas like floors or tabletops. Water-based polyurethane, while durable, may require more frequent touch-ups in heavily used spaces. For older wood, this decision should balance the desired look with the piece’s intended use.

Ultimately, the choice between oil- and water-based polyurethane depends on whether you want to enhance or preserve the wood’s natural beauty. If you’re aiming for a timeless, aged look with added warmth, oil-based is the way to go. For a crisp, contemporary finish that lets the wood speak for itself, water-based polyurethane is the better option. Always prepare the wood surface properly—sanding lightly and removing dust—to ensure adhesion and a flawless result.

Avery Woods' Husband's Age: Unveiling the Mystery Behind Their Love Story

You may want to see also

Explore related products

Application Tools: Use brushes, rollers, or sprayers for even coverage

Choosing the right application tool for polyurethane over old wood is crucial for achieving a smooth, even finish. Brushes, rollers, and sprayers each offer distinct advantages and are suited to different project needs. Brushes, for instance, provide excellent control and are ideal for detailed work or smaller surfaces. Natural bristle brushes are often recommended for oil-based polyurethanes, while synthetic brushes work well with water-based versions. However, brushes can leave visible strokes if not applied carefully, making them less ideal for large, flat surfaces.

Rollers, on the other hand, are efficient for covering large areas quickly and evenly. They are particularly useful for floors or tabletops, where a consistent finish is essential. Use a high-quality, shed-resistant roller cover to avoid lint contamination. For best results, apply the polyurethane in thin, even coats, working in the direction of the wood grain. Rollers can be paired with a brush for edges and corners, ensuring comprehensive coverage without overlap marks.

Sprayers offer the most uniform finish, especially for intricate or textured wood surfaces. They are the tool of choice for professionals seeking a flawless, factory-like appearance. However, sprayers require careful preparation, including masking off surrounding areas and ensuring proper ventilation. HVLP (High Volume Low Pressure) sprayers are recommended for polyurethane application, as they minimize overspray and provide better control. Practice on a scrap piece of wood to get a feel for the spray pattern and flow rate before tackling your project.

Each tool has its trade-offs. Brushes offer precision but demand skill to avoid streaks; rollers are efficient but can leave bubbles if overloaded; sprayers deliver perfection but require more setup and cleanup. The key is to match the tool to the project’s scale, complexity, and desired finish. For example, a small antique table might benefit from a brush for detailed work, while a large wooden floor would be better suited to a roller or sprayer.

Regardless of the tool chosen, proper technique is essential. Apply thin coats, allowing each layer to dry completely before sanding lightly (220-grit sandpaper) and applying the next. Overloading the tool or rushing the process can lead to drips, bubbles, or an uneven finish. Always follow the manufacturer’s instructions for drying times and application tips specific to the polyurethane product. With the right tool and careful execution, you can transform old wood into a durable, beautifully finished surface.

Can Sage Thrive on Aging Wood? Uncovering the Truth

You may want to see also

Explore related products

Coat Application: Apply thin, multiple coats, sanding lightly between layers

Applying polyurethane over old wood is an art that hinges on patience and precision. The key to a flawless finish lies in the application of thin, multiple coats, with light sanding between each layer. This method ensures a smooth, even surface that enhances the wood’s natural beauty without obscuring its character. Thick coats, while tempting for quicker coverage, often lead to drips, bubbles, or an uneven texture that can mar the final result. By contrast, thin coats allow the polyurethane to adhere properly, curing uniformly and building up to a durable, protective layer.

The process begins with preparation—cleaning the wood thoroughly to remove dust, grease, or old finishes. Once the surface is ready, apply the first coat with a high-quality brush or foam applicator, working in the direction of the grain. Aim for a thin, even layer, as if you’re painting with water rather than a viscous liquid. Allow this coat to dry completely, following the manufacturer’s recommended drying time, typically 2–4 hours depending on humidity and temperature. Rushing this step can cause the layers to blend, defeating the purpose of multiple coats.

Between coats, lightly sand the surface with 220–320 grit sandpaper. This step removes any imperfections, such as raised grain or dust particles, and creates a subtle texture for the next coat to grip. Wipe away the sanding residue with a tack cloth or a damp, lint-free cloth. The sanding should be gentle—just enough to smooth the surface without cutting through to the wood. Repeat the application and sanding process for 2–4 coats, depending on the desired thickness and protection level. Each coat adds depth and durability, but overdoing it can make the finish look plasticky or overly glossy.

A practical tip is to test the process on a scrap piece of similar wood or an inconspicuous area to gauge drying times and the finish’s appearance. For water-based polyurethanes, consider adding a flow control additive to reduce bubbles and improve application. Oil-based products may require thinning with mineral spirits if they appear too thick. Always work in a well-ventilated area, especially with oil-based finishes, and wear protective gear like gloves and a mask.

The final takeaway is that thin, multiple coats with light sanding between layers are not just a technique—they’re a philosophy. This approach respects the wood’s history while ensuring a professional, long-lasting finish. It’s a balance of craftsmanship and restraint, where each layer contributes to a cohesive whole. By embracing this method, you transform old wood into a timeless piece, preserving its story while adding a protective, lustrous sheen.

Unveiling Amy Wood's Age: A Comprehensive Look at Her Life

You may want to see also

Explore related products

Drying and Curing: Allow ample drying time and avoid use until fully cured

Polyurethane application over old wood is a delicate process, and the drying and curing phase is where patience truly pays off. The transformation from a liquid finish to a durable, protective coat requires time, often more than you might expect. For oil-based polyurethanes, the drying time between coats can range from 8 to 24 hours, while water-based versions may dry in as little as 2 to 4 hours. However, drying is just the first step; curing, which can take days or even weeks, is when the finish hardens completely and reaches its maximum durability. Rushing this process can lead to a marred surface, sticky residue, or weakened protection.

Consider the environmental factors that influence drying and curing times. Humidity, temperature, and airflow play significant roles. In high-humidity conditions, drying times can double, while low temperatures can slow the process to a crawl. Optimal conditions for curing are a temperature range of 70–75°F (21–24°C) and humidity below 50%. To expedite drying, ensure proper ventilation by opening windows or using fans, but avoid direct heat sources like heaters or sunlight, which can cause uneven drying and bubbling.

A common mistake is assuming the surface is ready for use once it feels dry to the touch. This is a critical error, as the finish may still be soft and susceptible to damage. For light use, such as placing objects on a table, wait at least 24–48 hours after the final coat. However, for heavy use, such as walking on floors or placing heavy furniture, allow a full 72 hours to a week. For maximum durability, especially in high-traffic areas, extend the curing period to 30 days. During this time, avoid dragging objects across the surface and use felt pads under furniture legs to prevent scratches.

To test if the polyurethane has fully cured, perform a simple "thumbprint test." Press your thumb firmly on the surface; if no imprint remains, the finish is cured. Another method is to tape a piece of masking tape to the surface and pull it off quickly. If the finish peels or sticks to the tape, it’s not fully cured. These tests are particularly useful for floors or large surfaces where visual inspection alone may not suffice.

In conclusion, drying and curing are not interchangeable terms but distinct phases in the polyurethane application process. While drying allows you to apply additional coats, curing ensures the finish reaches its full potential in hardness and durability. By respecting these timelines and adjusting for environmental conditions, you’ll achieve a professional-quality finish that protects and enhances your old wood for years to come. Patience in this stage is not just a virtue—it’s a necessity.

Does Old Barn Wood Last? Durability, Preservation, and Reuse Tips

You may want to see also

Frequently asked questions

It’s not recommended to apply polyurethane directly over old wood without sanding. Sanding removes the old finish, smooths the surface, and ensures proper adhesion of the new polyurethane. Skipping this step may result in poor adhesion, uneven finish, or peeling.

To prepare old wood, start by cleaning the surface to remove dirt, grease, or old wax. Then, sand the wood with progressively finer grits (e.g., 120, 150, and 220 grit) to smooth the surface and remove the old finish. Wipe away dust with a tack cloth before applying polyurethane.

Typically, 2-3 coats of polyurethane are sufficient for old wood. Apply thin, even coats, allowing each layer to dry completely (usually 2-4 hours) and lightly sanding with 220-grit sandpaper between coats for better adhesion. The final coat does not need sanding.