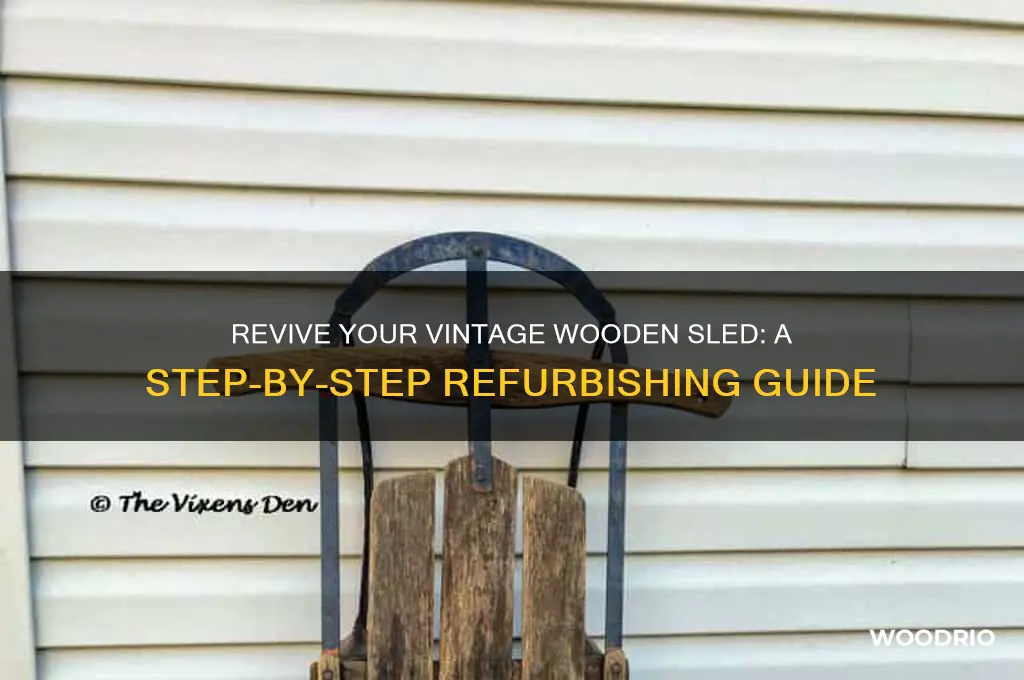

Refurbishing an old wooden sled is a rewarding project that breathes new life into a cherished winter classic. Begin by thoroughly inspecting the sled for damage, such as cracks, splinters, or loose parts, addressing these issues with wood glue, clamps, or replacement pieces as needed. Sand the entire surface to remove old paint, stains, or rough spots, ensuring a smooth base for refinishing. Apply a coat of wood sealant or stain to protect the sled from moisture and enhance its natural beauty, followed by a durable outdoor paint if desired. Finally, check and tighten all hardware, such as metal runners or bindings, and add a fresh coat of wax to the runners for smooth gliding. With care and attention to detail, your refurbished wooden sled will be ready for many more winters of snowy adventures.

| Characteristics | Values |

|---|---|

| Inspection | Thoroughly examine the sled for cracks, splinters, loose parts, and rusted hardware. |

| Cleaning | Remove dirt, grime, and old finish using a stiff brush, sandpaper, or a mild detergent solution. |

| Repairs | Fill cracks with wood filler, replace broken parts with matching wood, and tighten or replace loose hardware. |

| Sanding | Sand the entire sled progressively with finer grits of sandpaper (starting from coarse to fine) to smooth the surface and remove imperfections. |

| Finishing | Apply a suitable wood finish like varnish, polyurethane, or linseed oil to protect the wood and enhance its appearance. Consider multiple thin coats for best results. |

| Hardware Maintenance | Clean and lubricate metal runners and hardware to ensure smooth gliding and prevent rust. |

| Personalization | Add personal touches like painting, stenciling, or carving designs onto the sled. |

| Storage | Store the refurbished sled in a dry place to prevent warping and damage. |

Explore related products

$10.99

What You'll Learn

- Inspect for Damage: Check sled for cracks, splinters, loose parts, and structural integrity before starting repairs

- Sand and Smooth: Remove old paint, rough surfaces, and splinters using sandpaper for a clean base

- Repair and Replace: Fix cracks with wood glue, replace broken slats, and reinforce weak joints

- Paint or Stain: Apply primer, paint, or wood stain to protect and enhance the sled’s appearance

- Add Hardware: Reattach or replace runners, handles, and screws for functionality and safety

Inspect for Damage: Check sled for cracks, splinters, loose parts, and structural integrity before starting repairs

Before diving into the restoration of an old wooden sled, a meticulous inspection is paramount. Start by examining the sled for any visible cracks, especially in high-stress areas like the runners and the seat. Cracks can compromise the sled’s structural integrity and worsen during use, so identify them early. Use a bright light and a magnifying glass if necessary to spot hairline fractures that might otherwise go unnoticed.

Next, run your hands along the sled’s surface to detect splinters or rough patches. Splinters not only pose a safety hazard but can also indicate deeper wood deterioration. Sandpaper or a wood file can address minor issues, but significant splintering may require wood filler or replacement of the affected section. Always wear gloves during this step to avoid injury.

Loose parts, such as screws, bolts, or metal bindings, are another critical area to inspect. Wobbly handles or detached metal components can lead to accidents during use. Tighten loose hardware with the appropriate tools, and replace missing or damaged parts with matching materials to maintain the sled’s authenticity and functionality.

Finally, assess the sled’s overall structural integrity by applying gentle pressure to different areas. Sit on the sled (if it’s designed for seating) or simulate weight distribution to check for weakness. If the wood flexes excessively or emits creaking sounds, it may need reinforcement, such as adding braces or gluing joints with waterproof wood adhesive.

This inspection phase is not just about identifying problems—it’s about prioritizing safety and ensuring the sled’s longevity. Skipping this step could lead to mid-repair discoveries that complicate the process or render the sled unsafe for use. By addressing damage early, you lay the foundation for a successful refurbishment that honors the sled’s history while making it functional for years to come.

Eco-Friendly Ways to Dispose of Old Deck Wood Responsibly

You may want to see also

Explore related products

$54.99 $82.99

Sand and Smooth: Remove old paint, rough surfaces, and splinters using sandpaper for a clean base

The first step in reviving an old wooden sled is to strip away the past. Layers of weathered paint, rough patches, and splintered wood not only detract from its aesthetic but can compromise its functionality. Sanding is the cornerstone of this process, transforming a neglected relic into a smooth, safe, and visually appealing piece.

Begin with a medium-grit sandpaper, such as 120-grit, to tackle the bulk of the old paint and rough surfaces. This grit strikes a balance between aggressiveness and control, allowing you to remove imperfections without damaging the wood. For intricate areas or stubborn spots, consider using a sanding block or a power sander with a detail attachment to ensure even pressure and precision.

As you progress, the goal shifts from removal to refinement. Switch to a finer grit, like 220-grit, to smooth out the scratches left by the coarser paper. This step is crucial for achieving a polished finish and preparing the surface for staining, painting, or sealing. Pay special attention to edges and corners, where splinters are most likely to form, ensuring they are rounded and safe to the touch.

While sanding is essential, it’s equally important to approach it with care. Over-sanding can thin the wood, weakening its structure, especially in older sleds. Work in the direction of the grain to avoid creating cross-grain scratches, which can be difficult to correct. Regularly wipe the surface with a damp cloth to remove dust and assess your progress, ensuring you don’t go too far.

The result of this meticulous process is a clean, smooth base that breathes new life into the sled. It’s not just about aesthetics; a well-sanded surface enhances the adhesion of finishes, prolonging the sled’s lifespan. Whether you’re restoring a family heirloom or upcycling a flea market find, sanding is the foundation upon which all other refurbishment efforts rest. With patience and attention to detail, you’ll uncover the timeless beauty hidden beneath years of wear and tear.

Does Old Barn Wood Last? Durability, Preservation, and Reuse Tips

You may want to see also

Explore related products

Repair and Replace: Fix cracks with wood glue, replace broken slats, and reinforce weak joints

Cracks in an old wooden sled aren’t just unsightly—they compromise its structural integrity. Wood glue is your first line of defense. Choose a high-quality, waterproof wood glue designed for structural repairs. Apply it generously into the crack, using a thin spatula to ensure it penetrates deeply. Clamp the area firmly, if possible, and allow it to dry for at least 24 hours. For deeper cracks, consider filling them with wood filler after gluing to restore a smooth surface. Always sand the area lightly afterward to blend it with the surrounding wood.

Broken slats are a common issue in aged sleds, but replacing them isn’t as daunting as it seems. Measure the length and width of the damaged slat, then source a matching piece of wood from a hardware store or repurpose wood from another project. Cut the new slat to size, ensuring it fits snugly into the sled’s frame. Secure it with wood screws or nails, pre-drilling holes to prevent splitting. Stain or paint the new slat to match the original finish, maintaining the sled’s aesthetic appeal.

Weak joints are often the result of years of stress and wear. Reinforcing them is crucial for safety and longevity. Disassemble the joint if possible, clean out old glue, and apply a fresh layer of epoxy or wood glue. For added strength, insert wooden dowels or metal brackets into the joint before reassembling. If disassembly isn’t feasible, inject glue into the joint using a syringe and clamp or brace the area until it dries. Regularly inspect joints after refurbishment to catch any future weakening early.

While repairing cracks, replacing slats, and reinforcing joints are essential steps, they’re just part of a larger restoration process. Each repair should be approached with care, balancing functionality and preservation of the sled’s character. For antique sleds, consider consulting a professional to ensure historically accurate materials and techniques are used. With patience and attention to detail, your refurbished sled can glide through snow for years to come, blending old-world charm with renewed durability.

David Austin Roses: Blooming on Old Wood or New Growth?

You may want to see also

Explore related products

Paint or Stain: Apply primer, paint, or wood stain to protect and enhance the sled’s appearance

Protecting and enhancing the appearance of an old wooden sled begins with choosing the right finish. Paint and stain both offer unique benefits, but their application processes and outcomes differ significantly. Paint provides a vibrant, opaque layer that can completely transform the sled’s look, while stain penetrates the wood, enriching its natural grain and texture. Before deciding, consider the sled’s condition, desired aesthetic, and intended use—whether it’s a decorative piece or a functional winter accessory.

Steps for Application: Start by sanding the sled’s surface to remove old paint, rough patches, or splinters. Use 120-grit sandpaper for initial smoothing, followed by 220-grit for a finer finish. If using paint, apply a primer first to ensure adhesion and longevity. For stain, clean the wood thoroughly to allow even absorption. Apply the primer or stain in thin, even coats using a brush or sprayer, following the manufacturer’s drying times between layers. Paint typically requires 2–3 coats, while stain may need 1–2, depending on the desired depth of color.

Cautions and Considerations: Paint can hide imperfections but may chip or peel over time, especially in harsh outdoor conditions. Stain, while more forgiving, offers less protection against moisture and UV damage unless sealed with a topcoat. For outdoor sleds, choose exterior-grade paint or stain and apply a clear sealant for added durability. Avoid over-saturating the wood with stain, as it can lead to uneven coloring or a sticky surface. Always work in a well-ventilated area and wear protective gear, including gloves and a mask.

Comparative Analysis: Paint is ideal for those seeking a bold, customized look or needing to cover extensive damage. Stain, on the other hand, preserves the sled’s rustic charm and is better suited for vintage or sentimental pieces. For a middle ground, consider a tinted wood finish, which combines the protection of paint with the natural beauty of stain. Whichever option you choose, proper preparation and application are key to achieving a professional, long-lasting result.

Practical Tips: Test your chosen finish on a small, inconspicuous area to ensure it meets your expectations. For intricate designs or patterns, use painter’s tape to create clean lines. If refinishing a sled with historical value, consult a conservator to avoid damaging its integrity. Finally, store the sled in a dry, cool place when not in use to prolong the finish’s life. With the right approach, your refurbished sled will be both a functional and decorative masterpiece.

Endless Summer Hydrangea: Old Wood or New Wood Bloomers?

You may want to see also

Explore related products

$23.99

$178.6 $266.3

$56.99 $59.99

Add Hardware: Reattach or replace runners, handles, and screws for functionality and safety

The runners on a wooden sled are its lifeline, enduring the brunt of friction and cold. Over time, they warp, crack, or detach entirely, rendering the sled unsafe and unusable. Reattaching or replacing them is non-negotiable for functionality. Start by assessing the damage: minor cracks can be filled with wood epoxy, while severely damaged runners must be replaced. Use hardwood like ash or hickory for durability, ensuring the new runners match the original dimensions. Secure them with galvanized screws to prevent rust, pre-drilling holes to avoid splitting the wood. This step alone can transform a relic into a reliable winter companion.

Handles are the sled’s control center, and their absence or instability compromises safety. If the original handles are loose, remove them and inspect the mounting points. Reinforce weak areas with wood glue and clamps, allowing ample drying time. For missing or broken handles, opt for replacements made of sturdy materials like metal or hardwood. Attach them at a comfortable height and angle, typically 12–18 inches above the sled’s surface, ensuring a firm grip for both children and adults. Test the handles by applying pressure in all directions to confirm stability before use.

Screws are the unsung heroes of sled construction, holding everything together. Rusted or stripped screws must be replaced immediately, as they weaken the sled’s structure. Use stainless steel or galvanized screws of the same gauge to maintain integrity. When reattaching hardware, apply a thread-locking adhesive to the screws to prevent loosening over time. Periodically check all fasteners, especially after heavy use, and tighten as needed. This small but critical step ensures the sled remains safe for years to come.

Comparing the cost of new hardware to the value of safety, the investment is negligible. A set of runners costs $20–$50, handles $10–$30, and screws mere cents. Yet, these components are the difference between a sled that glides smoothly and one that fails mid-descent. Prioritize quality over price, as cheap replacements may not withstand winter conditions. By meticulously addressing each piece of hardware, you not only restore the sled’s functionality but also preserve its nostalgic charm, ensuring it’s ready for another generation of snowy adventures.

Hydrangea Blooming Secrets: Do Mop Heads Flower on Old Wood?

You may want to see also

Frequently asked questions

You'll need sandpaper (various grits), wood filler, primer, paint or stain, varnish or sealant, a brush or roller, and possibly replacement parts like runners or screws.

Use sandpaper or a power sander to strip away old paint or finish. Start with coarse grit (80-120) and progress to finer grit (220) for a smooth surface.

Yes, fill cracks or holes with wood filler, let it dry, and sand it smooth. For larger damage, consider gluing or clamping broken pieces together before filling.

Apply a coat of outdoor-grade varnish or sealant after painting or staining. Reapply annually to maintain protection against moisture and wear.