Drilling through old farmhouse wood requires careful consideration due to its age, potential brittleness, and unique characteristics. Unlike modern lumber, aged wood may contain hidden nails, knots, or cracks, making it prone to splitting or damage. To ensure a clean and safe hole, it's essential to use the right tools, such as a sharp, high-quality drill bit and a drill with adjustable speed settings. Pre-drilling pilot holes, using a backing board to prevent tear-out, and applying gentle pressure can help preserve the wood's integrity. Additionally, inspecting the wood for hidden obstructions and working slowly will minimize the risk of accidents or structural damage, allowing you to achieve precise results while maintaining the rustic charm of the farmhouse wood.

Explore related products

$14.79 $18.98

What You'll Learn

- Tools Needed: Essential tools for drilling through aged, hardened farmhouse wood safely and efficiently

- Wood Condition: Assessing wood density, rot, or damage before drilling to avoid breakage

- Drill Bit Selection: Choosing the right bit type and size for old, tough wood fibers

- Drilling Techniques: Slow, steady drilling methods to prevent splintering or cracking the wood

- Safety Tips: Protective gear and precautions to avoid injuries when working with aged wood

Tools Needed: Essential tools for drilling through aged, hardened farmhouse wood safely and efficiently

Drilling through aged, hardened farmhouse wood requires a strategic selection of tools to ensure precision, safety, and efficiency. The density and unpredictability of old wood demand specialized equipment that can handle its unique challenges, such as embedded nails, warping, and increased brittleness. Here’s a breakdown of the essential tools you’ll need for the task.

High-Quality Drill with Variable Speed Control

A powerful, corded drill with variable speed settings is non-negotiable. Aged wood can splinter or crack under high speeds, so the ability to adjust RPMs allows you to start slow and increase gradually as needed. Opt for a drill with at least 700 watts of power to handle the wood’s hardness without stalling. Corded models provide consistent power, eliminating the risk of battery drain mid-task.

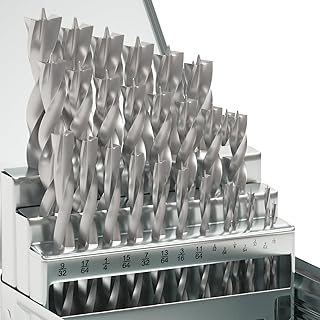

Titanium or Cobalt Drill Bits

Standard steel bits will dull quickly against hardened wood. Titanium-coated or cobalt bits are designed for durability and heat resistance, making them ideal for tough materials. For farmhouse wood, choose a set of bits ranging from 1/8 inch to 1/2 inch in diameter. Start with a smaller pilot hole to reduce the risk of splitting, then gradually increase the bit size if needed.

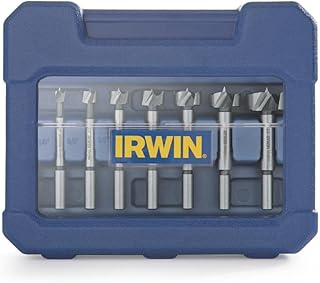

Wood-Specific Drill Bit Set with Brad Point

Brad point bits are engineered for clean, precise holes in wood. Their sharp, centered point prevents wandering, while the cutting edges reduce splintering. This is especially critical in aged wood, where the grain can be uneven. Use a brad point bit for any hole larger than 1/4 inch to maintain accuracy and minimize damage to the surrounding material.

Clamp and Backer Board

Securing the wood is as important as the drilling itself. Use a sturdy clamp to hold the piece in place, preventing movement that could lead to accidents or uneven holes. Pair this with a backer board—a sacrificial piece of wood placed behind the drilling area—to prevent blowout and provide a clean exit point for the bit. This simple setup ensures stability and protects the wood’s integrity.

Safety Gear: Eye Protection and Dust Mask

Drilling aged wood releases fine particles and debris that can irritate the eyes and lungs. Always wear safety goggles to shield your eyes from flying splinters. A dust mask, preferably with a respirator rating of N95 or higher, is essential to avoid inhaling wood dust, which can be harmful over time. These precautions are small but critical for long-term health.

By equipping yourself with these tools, you’ll be prepared to tackle the unique challenges of drilling through aged farmhouse wood. Each item serves a specific purpose, from preventing damage to ensuring your safety, allowing you to work efficiently and achieve professional results.

Rambling Roses: Blooming on Old Wood or New Growth?

You may want to see also

Explore related products

Wood Condition: Assessing wood density, rot, or damage before drilling to avoid breakage

Old farmhouse wood, with its weathered patina and historical charm, often conceals hidden vulnerabilities. Before drilling into it, assess its condition to prevent splitting, crumbling, or catastrophic breakage. Start by examining the surface for visible signs of rot, such as discoloration, softness, or a spongy texture. Press a screwdriver gently into suspect areas; if it penetrates easily, the wood is compromised and drilling there risks structural failure.

Density plays a critical role in drilling success. Hardwoods like oak or maple, common in older homes, are denser and more resistant to splitting than softer woods like pine. However, age can alter density. Tap the wood with a hammer; a hollow sound indicates decay or delamination, while a sharp, solid sound suggests intact density. For a more precise assessment, use a moisture meter to detect water damage, which weakens wood fibers. Readings above 20% moisture content signal trouble.

Damage assessment goes beyond surface-level inspection. Look for cracks, checks, or previous drill holes, which act as stress points. If drilling near a knot, angle the bit slightly away from it to avoid the harder, more brittle grain. For severely damaged areas, consider reinforcing the wood with epoxy or consolidating loose fibers with wood hardener before drilling.

Practical tip: Test your drill bit on a scrap piece of similar wood to gauge its condition. If the wood splinters excessively or the bit binds, adjust your approach. Use a smaller pilot hole or switch to a brad-point bit, which reduces tear-out in fragile wood. Always drill slowly, applying steady pressure, and prioritize preservation over speed.

In conclusion, treating old farmhouse wood with respect begins with understanding its condition. By assessing density, rot, and damage, you not only protect the wood’s integrity but also ensure your project’s longevity. Take the time to evaluate—it’s the difference between a repair and a restoration.

Pruning Old Wood Hydrangeas: A Step-by-Step Guide for Healthy Blooms

You may want to see also

Explore related products

Drill Bit Selection: Choosing the right bit type and size for old, tough wood fibers

Old farmhouse wood, often dense and hardened by decades of weathering, demands a strategic approach to drilling. The wrong bit can splinter, burn, or dull quickly, turning a simple task into a frustrating ordeal. Selecting the right drill bit type and size is crucial for clean, efficient holes without damaging the wood’s integrity.

Bit Type Matters: A Comparative Analysis

For aged wood fibers, high-speed steel (HSS) bits are often inadequate due to their tendency to overheat and blunt rapidly. Instead, opt for cobalt or carbide-tipped bits, which retain sharpness longer and handle the hardness of old wood. Cobalt bits, with their heat resistance, are ideal for prolonged drilling, while carbide-tipped bits excel in cutting through tough, fibrous grains. For softer sections or pilot holes, a brad-point bit provides precision, but its delicate tip may wear quickly in denser areas.

Size Selection: Balancing Precision and Durability

Start with a smaller bit size than your final hole diameter to reduce torque and prevent splitting. For example, use a 1/8-inch bit to create a pilot hole before advancing to a 1/2-inch bit. This gradual approach minimizes stress on the wood fibers and prolongs bit life. When drilling larger holes, step up incrementally (e.g., 1/4-inch to 3/8-inch to 1/2-inch) to maintain control and accuracy.

Practical Tips for Success

Always apply steady, moderate pressure to avoid overheating the bit. Use a sharp awl or nail to create a starting point for the bit, ensuring it doesn’t wander. For vertical or angled drilling, secure the wood with clamps to prevent movement. If the wood is particularly brittle, consider spraying the area with water or a lubricant to reduce friction and prolong bit life.

Cautions and Troubleshooting

Avoid forcing the drill, as excessive pressure can cause the bit to bind or break. If the bit begins to smoke or the wood shows signs of burning, stop immediately and allow the bit to cool. Check the bit’s sharpness regularly; a dull bit will tear rather than cut, leading to rough edges and potential splintering. For stubborn spots, switch to a fresh bit or re-evaluate your approach.

Choosing the right drill bit type and size for old farmhouse wood is a blend of science and patience. By selecting durable materials, starting small, and working methodically, you can preserve the wood’s character while achieving clean, professional results. The right tools and techniques transform a daunting task into a manageable—even rewarding—project.

Do Apple Trees Fruit on Old Wood? Uncovering the Truth

You may want to see also

Explore related products

Drilling Techniques: Slow, steady drilling methods to prevent splintering or cracking the wood

Old farmhouse wood, often weathered and aged, demands respect when drilling. Its inherent brittleness and unpredictable grain patterns make it susceptible to splintering and cracking under aggressive drilling. Slow, steady techniques are paramount to preserving the wood's integrity while achieving clean, precise holes.

Imagine the wood fibers as tightly woven threads. A rapid, forceful drill bit acts like a blunt needle, tearing and fraying the threads. Conversely, a slow, controlled approach allows the bit to gently part the fibers, minimizing damage.

Technique Breakdown:

- Speed Control: Set your drill to a low speed setting, ideally below 500 RPM. This reduces friction and heat buildup, both of which can exacerbate splintering.

- Pilot Hole Precision: Always start with a pilot hole using a smaller diameter bit. This initial hole guides the larger bit and prevents the wood from splitting under pressure. For hardwoods, a pilot hole diameter half the size of your final bit is recommended.

- Backer Board Backup: Place a sacrificial piece of wood behind the drilling area. This backer board provides support and prevents tear-out on the exit side of the hole.

- Lubrication: Consider applying a small amount of beeswax or paraffin wax to the drill bit. This acts as a lubricant, reducing friction and further minimizing heat generation.

Pro Tip: For particularly stubborn wood, dip the bit in wax and let it cool before drilling.

The Art of Patience: Drilling through old farmhouse wood is a test of patience. Rushing the process will inevitably lead to costly mistakes. Embrace the slow, deliberate rhythm, allowing the drill bit to do its work without forcing it. The reward is a clean, professional-looking hole that preserves the character and beauty of the aged wood.

Did Old Wooden Ships Leak? Unraveling the Myth of Seaworthiness

You may want to see also

Explore related products

Safety Tips: Protective gear and precautions to avoid injuries when working with aged wood

Working with aged wood from old farmhouses presents unique challenges, including brittle material, hidden nails, and potential contaminants like lead paint or mold. Before drilling, assess the wood’s condition—look for cracks, rot, or embedded metal. A single misstep can lead to splintered wood, broken bits, or personal injury. Always assume the wood is unpredictable and prepare accordingly.

Protective gear is non-negotiable. Wear ANSI-rated safety glasses to shield your eyes from flying debris, as aged wood tends to splinter aggressively. A dust mask or respirator with N95 or higher filtration is essential to avoid inhaling wood dust, which can carry harmful particles from decades-old treatments. For prolonged work, consider hearing protection, as older wood often requires more forceful drilling, increasing tool noise. Leather gloves can prevent splinters, but ensure they fit snugly to avoid catching on the drill.

Precautions extend beyond gear. Secure the wood firmly in a vise or clamp to prevent it from shifting under pressure, which can cause the drill bit to kick back. Use a sharp, high-quality bit designed for hardwood to minimize resistance and reduce the risk of binding. Start with a pilot hole to guide the bit and prevent the wood from cracking. If the wood is painted, test for lead using a home testing kit and take extra precautions, such as wetting the surface to minimize dust.

Finally, work in a well-ventilated area to disperse dust and fumes. Keep a first aid kit nearby for minor injuries, and know the location of your nearest emergency facility. Aged wood may be rich in history, but it demands respect and preparation to handle safely. Treat each project as a delicate operation, and you’ll preserve both the wood and yourself.

Blueberries: Understanding Growth on Old vs. New Wood for Optimal Harvest

You may want to see also

Frequently asked questions

Use a high-speed steel (HSS) or carbide-tipped drill bit, as they are durable and can handle the hardness and potential nails or screws embedded in old wood.

Use a sharp drill bit, drill at a slower speed, and consider using a pilot hole or a brad point bit to guide the drill and reduce splitting.

Wear safety goggles, check for hidden nails or screws with a stud finder or magnet, and ensure the wood is stable and secure before drilling.

Yes, you can reuse the wood, but fill any unwanted holes with wood filler or plugs, and sand the area smooth to maintain its appearance.

Apply gentle, consistent pressure, use a lubricant like wax or soap on the bit, and periodically back the drill out to clear wood chips from the hole.