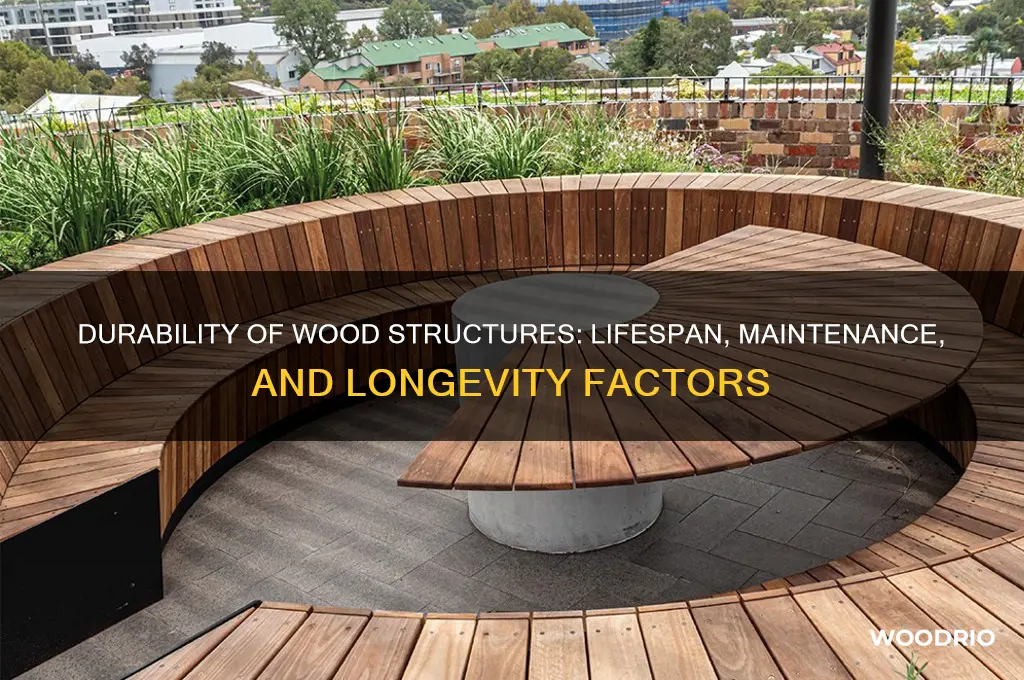

Wood structures, when properly designed, constructed, and maintained, can last for decades or even centuries, depending on factors such as the type of wood, environmental conditions, and protective treatments applied. Hardwoods like oak and cedar are naturally more durable and resistant to decay, while softer woods may require additional preservatives to extend their lifespan. Exposure to moisture, pests, and extreme weather can significantly impact longevity, making regular maintenance, such as sealing and inspections, crucial. With advancements in modern treatments like pressure-treating and composite materials, wood structures are increasingly resilient, offering a balance of aesthetic appeal and durability for both indoor and outdoor applications.

| Characteristics | Values |

|---|---|

| Average Lifespan (Treated Wood) | 40+ years |

| Average Lifespan (Untreated Wood) | 10-30 years |

| Lifespan with Proper Maintenance | Up to 100 years |

| Decay Resistance (Naturally Durable Woods) | 25-50+ years (e.g., Cedar, Redwood) |

| Decay Resistance (Pressure-Treated Wood) | 20-40 years |

| Insect Resistance (Naturally Resistant Woods) | 15-30+ years (e.g., Cypress, Teak) |

| Insect Resistance (Chemically Treated Wood) | 10-25 years |

| Fire Resistance | Low (can be improved with treatments) |

| Moisture Resistance (Without Treatment) | 5-15 years |

| Moisture Resistance (With Treatment) | 20-40+ years |

| UV Resistance (Without Protection) | 5-10 years |

| UV Resistance (With Protection) | 15-30+ years |

| Structural Integrity (Well-Maintained) | 50-100+ years |

| Environmental Factors Impact | Significant (climate, exposure, maintenance) |

| Cost-Effectiveness | High (compared to many alternatives) |

| Sustainability | Renewable and biodegradable |

Explore related products

$53.16 $69.95

What You'll Learn

Climate impact on wood durability

Wood durability is a delicate dance with climate, where temperature, humidity, and precipitation dictate the rhythm of decay. In tropical regions, where temperatures hover between 25°C and 30°C (77°F and 86°F) and annual rainfall exceeds 2000 mm (79 inches), wood structures face a formidable foe: fungal decay. High moisture content, typically above 20%, creates an ideal breeding ground for fungi, which can reduce the lifespan of untreated wood to a mere 5-10 years. In contrast, arid climates with less than 250 mm (10 inches) of annual rainfall and temperatures exceeding 35°C (95°F) present a different challenge: UV radiation and thermal degradation. Here, wood may last 15-20 years, but its surface will crack, warp, and lose structural integrity over time.

Consider the role of humidity, a silent yet potent force in wood deterioration. In coastal areas with relative humidity levels consistently above 70%, wood absorbs moisture like a sponge, expanding and contracting with each cycle. This movement weakens the cellular structure, making it susceptible to insect infestation and rot. For instance, termites thrive in humid environments, causing up to 30% loss in wood density within 3 years. To mitigate this, apply moisture-resistant treatments such as creosote or copper azole, which can extend wood life by 2-3 times in high-humidity zones.

Temperature extremes act as a double-edged sword, accelerating degradation in both hot and cold climates. In regions with freezing winters, wood repeatedly exposed to temperatures below 0°C (32°F) experiences frost damage. Ice crystals form within the wood cells, causing them to rupture and reducing tensile strength by up to 40%. Conversely, in hot climates, temperatures above 40°C (104°F) accelerate oxidation, breaking down lignin and cellulose. Applying UV-resistant coatings and thermal barriers can reduce surface temperature by 10-15°C, significantly slowing degradation.

Rainfall patterns provide a final, critical variable in the climate-wood durability equation. In areas with intense, sporadic rainfall, such as monsoon regions, wood is subjected to rapid wetting and drying cycles. This causes internal stresses, leading to checks, splits, and warping. For example, untreated pine in such conditions may fail structurally within 7 years. Incorporating water-repellent sealants and designing structures with proper drainage can reduce moisture absorption by 50%, doubling the wood’s lifespan.

To maximize wood durability in any climate, adopt a multi-pronged strategy. In wet climates, elevate structures on foundations to reduce ground contact and ensure ventilation. In dry climates, use shade structures to minimize UV exposure. Regularly inspect for signs of decay, such as discoloration or softness, and treat with fungicides or insecticides as needed. By understanding and adapting to climate-specific challenges, wood structures can endure for decades, blending functionality with natural beauty.

Mastering Precision: Drilling Long, Straight Holes in Wood Effortlessly

You may want to see also

Explore related products

Types of wood and longevity

Wood structures, when properly maintained, can endure for centuries, but the type of wood used plays a pivotal role in determining their lifespan. For instance, teak, a dense and oily hardwood, is renowned for its exceptional durability, often lasting 50 to 100 years in outdoor structures like decks and bridges. Its natural resistance to rot, insects, and moisture makes it a premium choice, though its cost reflects its longevity. In contrast, softer woods like pine, while more affordable, typically last only 10 to 20 years outdoors without treatment. Understanding these differences is crucial for anyone planning a wood-based project.

To maximize longevity, consider the environment where the wood will be used. Tropical hardwoods like ipe and mahogany thrive in humid climates due to their inherent resistance to decay and pests, often lasting 40 to 75 years in such conditions. In drier regions, cedar and redwood are excellent choices, as their natural oils repel insects and resist warping, ensuring a lifespan of 20 to 30 years with minimal maintenance. For interior structures, oak and maple are ideal, offering durability and aesthetic appeal for up to 100 years when protected from moisture and pests.

Treatment and maintenance significantly extend the life of wood structures, regardless of type. Pressure-treated pine, for example, can last 20 to 40 years outdoors by incorporating preservatives that ward off rot and insects. Regular sealing or staining every 2 to 3 years further protects wood from UV damage and moisture infiltration. For hardwoods, while naturally durable, periodic cleaning and refinishing can enhance their appearance and structural integrity. Investing in proper care ensures that even less durable woods can outperform expectations.

When selecting wood, balance cost, durability, and environmental impact. Reclaimed wood, for instance, offers a sustainable option with unique character, often lasting as long as new wood when properly restored. Engineered wood products like laminated veneer lumber (LVL) combine the strength of hardwoods with consistency, making them suitable for load-bearing structures with lifespans of 50 to 100 years. By aligning wood type with specific needs and committing to maintenance, builders can create structures that stand the test of time.

When Will Your Pressure-Treated Fence Fade to Grey?

You may want to see also

Explore related products

$227.02 $379.99

Maintenance practices for extended lifespan

Wood structures, when properly maintained, can endure for centuries, as evidenced by historic timber-framed buildings still standing today. However, their longevity hinges on consistent care tailored to their environment and use. The first critical practice is regular inspection, ideally conducted biannually in spring and fall. Look for signs of moisture intrusion, such as warping, discoloration, or mold, as water is wood’s primary enemy. Pay close attention to areas prone to rot, like joints, sills, and foundations. Early detection of issues like termite damage or fungal growth can prevent costly repairs and extend the structure’s lifespan significantly.

Moisture management is the cornerstone of wood preservation. Ensure proper drainage around the structure by maintaining a slope of at least 5% away from the foundation. Gutters and downspouts should be cleaned and repaired to direct water away from wood surfaces. For elevated structures, like decks or piers, use pressure-treated lumber or apply water-repellent sealants every 2–3 years. In humid climates, consider installing vapor barriers or dehumidifiers in enclosed spaces to reduce moisture levels. For exterior wood, a breathable sealant allows the material to expand and contract naturally while repelling water.

Protective treatments play a vital role in safeguarding wood from environmental stressors. For instance, borate-based preservatives can be applied to untreated wood to deter insects and fungi. These treatments are particularly effective in preventing termite infestations and are safe for indoor use. For outdoor structures, UV-resistant stains or paints should be reapplied every 3–5 years to shield against sun damage, which can cause cracking and fading. In coastal areas, where salt exposure is a concern, use marine-grade sealants designed to resist corrosion and degradation.

Structural reinforcement becomes necessary as wood ages and loses strength. Weakened beams or posts should be sistered with new lumber rather than replaced entirely, saving time and preserving the structure’s integrity. For historic buildings, consult a preservation specialist to ensure repairs align with original construction techniques. Regularly tighten hardware like bolts and brackets to prevent loosening due to wood movement. In high-traffic areas, such as floors or staircases, consider adding protective finishes or rugs to minimize wear and tear.

Finally, proactive measures can preempt many common issues. Trim vegetation at least 12 inches away from wood structures to reduce moisture retention and discourage pests. Install metal flashing where wood meets masonry to prevent water wicking. For decks, use stainless steel or galvanized fasteners to avoid rust stains and structural compromise. By combining these practices, wood structures can not only survive but thrive, blending durability with timeless aesthetic appeal.

From Forest to Factory: Crafting Long Wooden Planks Explained

You may want to see also

Explore related products

Pest and decay resistance factors

Wood structures, when properly maintained, can endure for centuries, as evidenced by ancient timber buildings still standing today. However, their longevity is significantly influenced by pest and decay resistance factors. These factors are not inherent to all wood types and often require proactive measures to ensure durability. For instance, naturally resistant woods like cedar and redwood contain oils and tannins that deter insects and fungi, making them ideal for outdoor structures. Conversely, softer woods like pine are more susceptible and may require treatment to enhance their resilience. Understanding these differences is crucial for selecting the right material and implementing protective strategies.

One of the most effective methods to enhance pest and decay resistance is through chemical treatments. Pressure-treating wood with preservatives such as chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ) can extend its lifespan by decades. For example, ACQ-treated wood is commonly used in decking and fencing, offering up to 40 years of protection against termites and fungal decay. It’s important to follow manufacturer guidelines for application, ensuring the wood is thoroughly saturated. However, caution must be exercised with CCA-treated wood, as it contains arsenic and is no longer recommended for residential use due to health concerns.

Physical barriers and design considerations also play a vital role in minimizing pest and decay risks. Proper ventilation and moisture management are critical, as damp conditions accelerate wood deterioration and attract pests. Elevating wooden structures off the ground using concrete piers or metal bases can prevent direct contact with soil, reducing moisture absorption and termite access. Additionally, incorporating drainage systems and using water-resistant barriers can further safeguard against decay. These measures, combined with regular inspections, can significantly prolong the life of wood structures.

For those seeking eco-friendly alternatives, thermal modification and natural oils offer viable options. Thermally modified wood, treated at high temperatures to alter its cellular structure, becomes highly resistant to decay and insects without chemical additives. This process can increase wood’s lifespan by 25–30 years, making it suitable for outdoor applications. Similarly, applying natural oils like linseed or tung oil can enhance resistance while maintaining the wood’s aesthetic appeal. These methods are particularly appealing for environmentally conscious projects, though they may require more frequent reapplication compared to chemical treatments.

In conclusion, pest and decay resistance factors are pivotal in determining the longevity of wood structures. By selecting naturally resistant wood species, applying chemical treatments, implementing physical barriers, or opting for eco-friendly alternatives, one can significantly mitigate risks. Each approach has its advantages and limitations, and the choice depends on the specific application, environmental conditions, and personal preferences. Proactive measures not only preserve the structural integrity of wood but also ensure its sustainability for future generations.

Driftwood vs. Stone: Which Natural Material Outlasts the Other?

You may want to see also

Explore related products

Treatment methods to preserve wood structures

Wood structures, when left untreated, can succumb to decay, insect damage, and weathering within a decade or two. However, with proper preservation methods, their lifespan can extend to 40 years or more, even in harsh environments. The key lies in understanding and applying treatment methods that address the primary threats to wood: moisture, fungi, and insects.

Pressure Treatment: The Gold Standard

Pressure-treating wood involves infusing preservatives like chromated copper arsenate (CCA) or alkaline copper quaternary (ACQ) into the material under high pressure. This process ensures deep penetration, protecting the wood from rot, termites, and fungal decay. For optimal results, use ACQ-treated wood for above-ground structures and CCA alternatives for ground-contact applications. Note: CCA is restricted in some regions due to arsenic concerns, so always check local regulations.

Coatings and Sealants: Surface-Level Defense

While not as durable as pressure treatment, coatings like paint, stain, and sealants provide a barrier against moisture and UV damage. Apply a water-repellent sealer annually to exposed wood surfaces, ensuring complete coverage. For added protection, use paints or stains with mildewcides and UV inhibitors. Pro tip: Sand the surface lightly before reapplication to ensure proper adhesion.

Natural Oils: Eco-Friendly Preservation

For those seeking chemical-free options, natural oils like linseed, tung, or hemp oil can enhance wood’s resistance to moisture and cracking. Apply a generous coat, allow it to penetrate for 12–24 hours, and wipe off excess. Repeat every 6–12 months, depending on exposure. While less effective against insects, these oils are ideal for indoor or lightly exposed structures.

Heat Treatment: A Chemical-Free Alternative

Thermally modifying wood involves heating it to high temperatures (180–240°C) in a controlled environment, altering its cellular structure to resist moisture and decay. This method, while costly, is eco-friendly and ideal for saunas, decks, and cladding. Treated wood can last 25+ years with minimal maintenance. Caution: Heat-treated wood may darken and become brittle, so handle with care during installation.

By combining these methods—pressure treatment for structural integrity, coatings for surface protection, natural oils for eco-conscious care, and heat treatment for longevity—wood structures can withstand the test of time, blending durability with aesthetic appeal.

Metal vs. Wood Porch Swings: Which Lasts Longer Outdoors?

You may want to see also

Frequently asked questions

Wood structures can last anywhere from 20 to 100+ years, depending on factors like wood type, maintenance, climate, and construction quality.

Yes, hardwoods like cedar, redwood, and teak are more durable and can last 40+ years, while softer woods like pine may last 15–30 years without proper treatment.

Extreme weather, such as heavy rain, snow, or humidity, can accelerate decay, rot, and insect damage, reducing the lifespan of wood structures if not properly protected.

Absolutely. Regular staining, sealing, and inspections can prevent moisture damage, insect infestations, and rot, potentially doubling or tripling the structure's lifespan.

Proper construction techniques, including adequate ventilation, moisture barriers, and correct fastening, significantly enhance durability and can extend the life of a wood structure by decades.