Bondo, a popular polyester-based filler commonly used for repairing wood, metal, and other surfaces, is known for its durability and versatility. When applied to wood, Bondo can last for many years, depending on factors such as the quality of application, environmental conditions, and the type of wood being repaired. Proper surface preparation, including cleaning, sanding, and priming, is crucial to ensure adhesion and longevity. In ideal conditions, such as indoor use with minimal exposure to moisture and temperature fluctuations, Bondo can remain effective for decades. However, outdoor applications or exposure to harsh elements may shorten its lifespan, requiring periodic maintenance or reapplication to maintain its structural integrity and appearance. Understanding these variables is essential for maximizing the durability of Bondo on wood surfaces.

| Characteristics | Values |

|---|---|

| Durability on Wood | Bondo, a polyester-based filler, can last 5-10 years on wood when properly applied and maintained. |

| Factors Affecting Longevity | - Moisture Exposure: Reduced lifespan in damp or wet conditions. - UV Exposure: Sunlight can degrade Bondo over time. - Surface Preparation: Proper sanding and priming extend durability. - Coating: Applying paint or sealant enhances longevity. |

| Indoor vs. Outdoor Use | - Indoor: Can last up to 10+ years with minimal exposure to elements. - Outdoor: Typically lasts 3-7 years due to weather exposure. |

| Flexibility | Bondo is rigid and may crack if the wood expands or contracts significantly. |

| Resistance to Rot | Does not prevent wood rot; the wood itself must be treated or resistant. |

| Maintenance Required | Periodic inspection and reapplication of protective coatings are necessary for outdoor use. |

| Compatibility with Wood | Best used for small repairs or filling gaps; not suitable for structural repairs. |

| Environmental Impact | Contains volatile organic compounds (VOCs); proper ventilation is required during application. |

| Cost-Effectiveness | Relatively inexpensive and widely available, making it a popular choice for minor wood repairs. |

Explore related products

$14.19 $16.8

What You'll Learn

Bondo's durability on wood surfaces

Bondo, a popular polyester-based filler, is often used to repair wood surfaces, but its longevity depends on several factors. When applied correctly, Bondo can last anywhere from 5 to 15 years on wood, depending on environmental conditions and maintenance. For instance, indoor applications with minimal exposure to moisture and temperature fluctuations tend to outlast outdoor uses, where UV rays and humidity accelerate degradation. Proper surface preparation, such as sanding and cleaning the wood, is critical to ensuring adhesion and maximizing durability.

To enhance Bondo’s lifespan on wood, follow these steps: first, clean the wood surface thoroughly to remove dirt, grease, and loose fibers. Next, apply a thin layer of Bondo, ensuring it’s evenly distributed and pressed firmly into any gaps or cracks. Allow it to cure fully, typically 20–30 minutes for most formulations, before sanding smooth. For added protection, especially in outdoor settings, seal the repaired area with a high-quality wood sealer or paint. This not only extends the life of the Bondo but also blends the repair seamlessly with the surrounding wood.

A comparative analysis reveals that while Bondo is durable, it may not match the longevity of epoxy-based fillers, which can last 20+ years on wood. However, Bondo’s affordability and ease of use make it a practical choice for many DIY enthusiasts. For example, a 1-quart tub of Bondo costs around $10–$15, compared to $20–$30 for epoxy fillers. If you’re repairing a wooden table with minor cracks, Bondo’s quick curing time and sandability make it ideal for small-scale projects where extreme durability isn’t a priority.

One cautionary note: Bondo is not recommended for structural wood repairs, as it lacks the flexibility to withstand significant movement or weight. For load-bearing applications, such as repairing a wooden beam, consult a professional or opt for a more robust material like epoxy or wood epoxy putty. Additionally, avoid using Bondo on wood surfaces that will be in constant contact with water, as prolonged moisture exposure can cause it to soften and fail prematurely. Always assess the specific demands of your project before choosing Bondo as your repair medium.

Understanding Standard Lengths of 1-Inch Thick Wood Planks

You may want to see also

Explore related products

Factors affecting Bondo lifespan on wood

Bondo's durability on wood hinges on several key factors, each playing a critical role in determining how long the repair will last. One of the most significant factors is the type of wood being repaired. Softwoods like pine or cedar, which are more porous and prone to moisture absorption, may not hold Bondo as effectively as hardwoods like oak or maple. The natural oils and density of hardwoods provide a more stable base for Bondo to adhere to, potentially extending its lifespan. For instance, a Bondo repair on a pine door might last 5–7 years, while the same repair on an oak surface could endure for 10–15 years under similar conditions.

Surface preparation is another critical factor that can make or break Bondo's longevity. Properly cleaning, sanding, and priming the wood before application ensures maximum adhesion. Neglecting to remove dirt, grease, or old finishes can lead to premature failure. For optimal results, sand the wood to a 120-grit finish, wipe away dust with a tack cloth, and apply a thin coat of epoxy primer. This preparatory step can add 2–3 years to the repair’s lifespan, especially in high-moisture environments like bathrooms or outdoor furniture.

The application technique also significantly impacts Bondo's durability. Overloading the mixture with hardener can cause it to crack as it cures, while under-mixing results in weak, crumbly patches. Follow the manufacturer’s instructions precisely: mix 1 part hardener to 20 parts resin (by volume) for wood repairs. Apply thin layers, allowing each to cure fully before sanding and adding another. This layered approach reduces stress on the material and ensures a stronger bond, potentially doubling the repair’s lifespan compared to a single thick application.

Environmental conditions, particularly moisture and temperature, are external factors that can accelerate Bondo’s deterioration. Prolonged exposure to water or high humidity can cause the repaired area to swell, crack, or delaminate. Similarly, extreme temperature fluctuations can weaken the bond between Bondo and wood. To mitigate this, seal Bondo repairs with a waterproof sealant or paint, especially for outdoor applications. In coastal or humid climates, consider using a marine-grade epoxy instead of standard Bondo for added resilience.

Finally, the intended use of the repaired wood surface plays a role in Bondo’s lifespan. High-traffic areas like floors or tabletops will wear down faster than stationary pieces like wall panels or decorative trim. For heavily used surfaces, reinforce Bondo repairs with fiberglass mesh or fabric for added strength. Regular maintenance, such as re-sealing every 2–3 years, can also extend the repair’s life. By considering these factors and tailoring your approach, you can maximize Bondo’s effectiveness and ensure long-lasting results on wood.

Exploring the Length of Night in the Woods: A Detailed Guide

You may want to see also

Explore related products

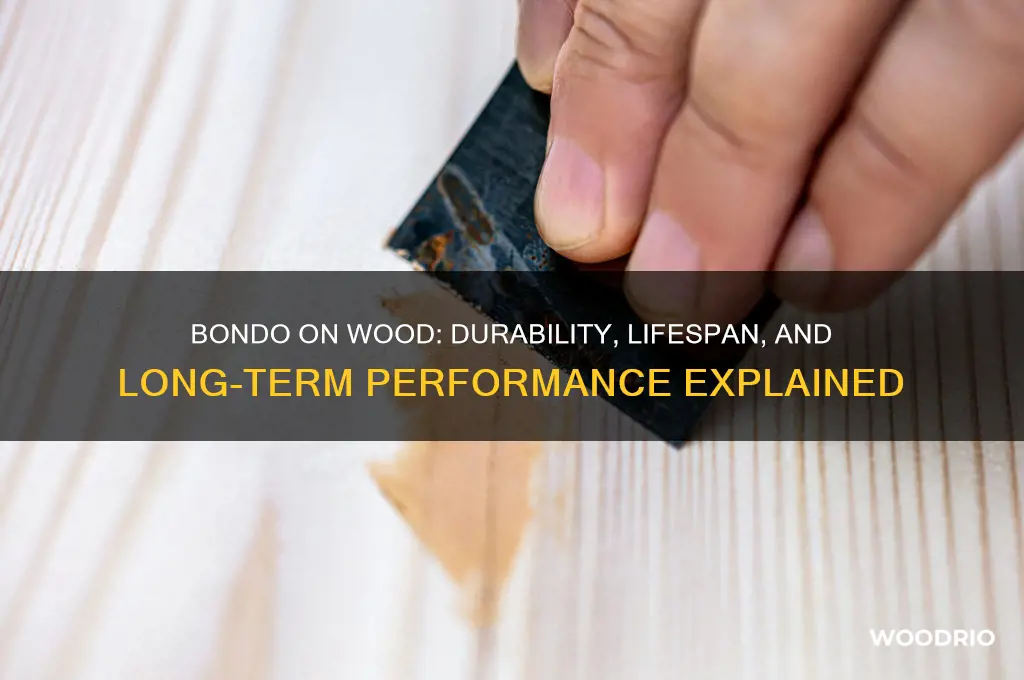

Proper application for longevity on wood

Bondo, a polyester-based filler commonly used for auto body repairs, can also be applied to wood to fill gaps, cracks, or imperfections. However, its longevity on wood depends heavily on proper application techniques. Unlike metal, wood is a porous, organic material that expands and contracts with changes in moisture and temperature. This movement can cause Bondo to crack or detach if not applied correctly. To ensure durability, the wood surface must be prepared meticulously, and the Bondo must be applied in a way that accommodates the wood’s natural tendencies.

Preparation is Key: Before applying Bondo, the wood surface must be clean, dry, and free of loose debris. Sand the area to create a rough texture, which helps the Bondo adhere better. For deeper repairs, ensure the wood is structurally sound; Bondo is not a structural adhesive and cannot replace rotten or damaged wood. If the wood is prone to moisture exposure, consider sealing it with a wood preservative or primer before application. This step is particularly crucial for outdoor projects, where humidity and temperature fluctuations are more extreme.

Application Technique: When mixing Bondo, follow the manufacturer’s instructions precisely. A common ratio is 1 part hardener to 25 parts filler, but this can vary by product. Over-mixing or under-mixing can compromise the cure, leading to premature failure. Apply the Bondo in thin layers, allowing each layer to cure fully before sanding and adding another. Thick applications are more prone to cracking as the wood moves. For larger repairs, use a reinforcing mesh or fiberglass cloth between layers to add flexibility and strength.

Sealing and Finishing: Once the Bondo is cured and sanded smooth, it must be sealed to protect it from moisture and UV damage. A high-quality primer followed by a durable paint or varnish is essential, especially for outdoor applications. Avoid oil-based finishes, as they can cause the Bondo to soften over time. For indoor projects, a clear polyurethane coat can provide both protection and a natural wood appearance. Regular maintenance, such as re-sealing every 2–3 years, can significantly extend the life of the repair.

Environmental Considerations: The lifespan of Bondo on wood varies depending on environmental conditions. In dry, temperature-controlled indoor settings, properly applied Bondo can last 10–15 years or more. Outdoors, however, exposure to rain, sun, and temperature extremes reduces this to 5–7 years, even with optimal application. To maximize longevity, consider the wood’s intended use and environment during the preparation and finishing stages. For example, marine-grade sealants and UV-resistant paints are ideal for outdoor furniture or structures.

By following these steps—thorough preparation, precise application, proper sealing, and consideration of environmental factors—Bondo can provide a long-lasting repair on wood surfaces. While it may not be as permanent as wood-specific fillers, its versatility and strength make it a viable option when used correctly. Regular inspection and maintenance will ensure the repair remains intact, preserving both the functionality and appearance of the wood.

Drying Wood Discs: Timeframe and Tips for Perfect Results

You may want to see also

Explore related products

Bondo vs. wood rot resistance

Bondo, a polyester-based filler commonly used for auto body repairs, is sometimes applied to wood to address imperfections or damage. However, its longevity on wood, particularly in the context of resisting wood rot, is a nuanced topic. Bondo is not inherently designed to combat moisture or fungal growth, the primary culprits behind wood rot. While it can temporarily fill cracks or holes, its effectiveness diminishes when exposed to damp or humid conditions. Wood, being a natural material, absorbs and releases moisture, which can cause Bondo to crack, peel, or delaminate over time. This vulnerability underscores the importance of understanding Bondo’s limitations in wood applications.

To maximize Bondo’s durability on wood, proper surface preparation is critical. The wood must be clean, dry, and free of loose debris. Sanding the area to create a rough surface enhances adhesion, and applying a primer specifically designed for wood can improve bonding. However, even with meticulous preparation, Bondo’s resistance to wood rot remains inferior to specialized wood fillers or treatments. For instance, epoxy-based wood fillers are more moisture-resistant and flexible, making them better suited for areas prone to dampness. Bondo’s polyester composition lacks the flexibility to withstand wood’s natural expansion and contraction, which can lead to failure in outdoor or high-moisture environments.

A comparative analysis reveals that while Bondo can last 5–10 years on wood under ideal conditions (e.g., indoor use with minimal moisture exposure), its lifespan drops significantly in harsher settings. In contrast, epoxy fillers or wood hardeners can endure 15–20 years or more, especially when combined with preventive measures like sealants or paint. For example, treating wood with a borate solution before applying Bondo can inhibit fungal growth, but this adds complexity and cost. The takeaway is clear: Bondo is a temporary solution for wood repair, not a long-term defense against rot.

Practical tips for using Bondo on wood include avoiding outdoor applications unless the wood is well-sealed and protected from moisture. For minor indoor repairs, such as filling nail holes or small cracks, Bondo can be effective if the wood is stable and dry. Always follow the manufacturer’s instructions for mixing ratios (typically 2% cream hardener to filler by weight) and curing times. However, for structural repairs or areas at risk of rot, prioritize epoxy-based products or professional wood restoration methods. Understanding these distinctions ensures that Bondo is used appropriately, avoiding costly failures and prolonging the life of wood structures.

Buffalo's Wood Fence Lifespan: Factors Affecting Durability in Harsh Winters

You may want to see also

Explore related products

Maintenance tips to extend Bondo's life on wood

Bondo, a popular polyester-based filler, can last on wood for several years if properly applied and maintained. However, its longevity depends on factors like exposure to moisture, temperature fluctuations, and physical stress. To maximize its lifespan, consider these maintenance tips tailored to its unique properties and common challenges.

Surface Preparation and Application Precision

The foundation of Bondo’s durability lies in meticulous preparation. Before application, ensure the wood is clean, dry, and free of loose debris. Sand the area lightly to create a rough surface, enhancing adhesion. When mixing Bondo, follow the manufacturer’s ratio (typically 2% hardener by volume) and work quickly, as it cures within 5–20 minutes. Apply thin layers rather than a single thick coat to prevent cracking. Properly feathering the edges during application ensures a seamless blend with the wood, reducing stress points that could lead to premature failure.

Protective Coatings and Environmental Shielding

Once cured, Bondo requires a protective barrier to resist moisture and UV damage. Apply a primer within 24 hours of curing, followed by a high-quality exterior paint or sealant. For outdoor applications, choose UV-resistant coatings to prevent discoloration and degradation. In high-moisture areas, consider marine-grade varnishes or epoxy sealers. Regularly inspect the finish for cracks or chips, and reapply coatings every 1–2 years to maintain protection. Avoid placing Bondo-repaired wood in direct contact with soil or standing water, as these conditions accelerate deterioration.

Routine Inspection and Timely Repairs

Even with proper care, Bondo may develop hairline cracks or delamination over time. Conduct bi-annual inspections, especially after extreme weather events. Use a magnifying glass to detect micro-fractures and address them promptly with a fresh layer of Bondo. For larger repairs, remove the damaged area with a chisel or rotary tool, clean the surface, and reapply the filler. Ignoring minor issues can lead to water infiltration, causing the wood substrate to rot and compromising the entire repair.

Temperature and Humidity Management

Bondo’s flexibility diminishes in extreme temperatures, making it prone to cracking in cold climates or softening in heat. For outdoor projects, choose a flexible additive designed for wood repairs to improve resilience. In indoor applications, maintain stable humidity levels (40–60%) to prevent wood expansion and contraction, which can stress the filler. Avoid placing Bondo-repaired wood near heat sources or in areas with drastic temperature swings, such as attics or uninsulated garages.

By combining precise application techniques, protective coatings, regular maintenance, and environmental awareness, you can significantly extend Bondo’s life on wood. While it may not last indefinitely, these strategies ensure it remains functional and aesthetically pleasing for 5–10 years or more, depending on conditions.

Durability of Wood Gazebos: Lifespan and Maintenance Tips

You may want to see also

Frequently asked questions

Bondo can last for many years on wood, depending on factors like application quality, environmental conditions, and maintenance. Properly applied and sealed, it can endure for decades.

Bondo can deteriorate if exposed to moisture, extreme temperatures, or UV rays. Sealing it with paint or varnish helps prolong its lifespan.

Bondo can withstand outdoor conditions if properly sealed and maintained. However, prolonged exposure to harsh weather may reduce its durability.

Inspect Bondo on wood annually, especially if it’s outdoors, to check for cracks, peeling, or other signs of wear that may require repair.

Yes, Bondo on wood can be repaired by sanding down the damaged area and reapplying Bondo. If the damage is extensive, it may need to be replaced entirely.