Wood dust, a byproduct of woodworking activities such as sawing, sanding, and routing, can remain suspended in the air for varying lengths of time depending on factors like particle size, air movement, and ventilation. Finer particles, typically smaller than 10 microns, can stay airborne for hours or even days, posing significant health risks such as respiratory issues and long-term conditions like occupational asthma or lung cancer. Larger particles tend to settle more quickly, often within minutes to hours. Proper ventilation, dust extraction systems, and personal protective equipment are essential to minimize airborne wood dust and protect workers from its harmful effects. Understanding how long wood dust remains in the air is crucial for implementing effective safety measures in woodworking environments.

| Characteristics | Values |

|---|---|

| Particle Size | Smaller particles (<10 μm) can remain suspended for hours to days. |

| Airflow and Ventilation | High airflow disperses dust quickly; poor ventilation prolongs suspension. |

| Humidity | High humidity causes particles to settle faster due to increased weight. |

| Temperature | Warmer air keeps particles suspended longer; cooler air aids settling. |

| Dust Concentration | Higher concentrations increase suspension time due to particle collisions. |

| Settling Time | Fine wood dust (<5 μm) can stay airborne for days; larger particles settle within hours. |

| Indoor vs. Outdoor | Indoor environments with limited airflow retain dust longer than outdoors. |

| Health Risks | Prolonged exposure to airborne wood dust increases respiratory risks (e.g., asthma, cancer). |

| Regulatory Limits | OSHA limits wood dust exposure to 5 mg/m³ (8-hour TWA) to minimize health risks. |

| Control Measures | Proper ventilation, dust extraction systems, and PPE reduce airborne dust duration. |

Explore related products

What You'll Learn

Factors affecting wood dust suspension time

Wood dust suspension time in the air is influenced by a complex interplay of factors, each contributing to how long particles remain airborne. Understanding these factors is crucial for managing air quality in woodworking environments and mitigating health risks such as respiratory issues or explosions. Particle size, air currents, humidity, and temperature collectively determine the fate of wood dust once it becomes airborne.

Particle Size and Shape: The Foundation of Suspension

Smaller wood dust particles, typically those under 10 micrometers (μm) in diameter, can remain suspended for hours or even days due to their reduced settling velocity. Particles larger than 100 μm settle quickly, often within minutes. Irregularly shaped particles, common in wood dust, may exhibit unpredictable aerodynamics, prolonging suspension compared to spherical particles of similar size. For example, sanding operations generate finer dust that stays airborne longer than coarser sawdust from cutting.

Air Movement: The Invisible Hand

Air currents, whether natural or mechanical, significantly extend suspension time by preventing particles from settling. In woodworking shops, fans, open windows, or HVAC systems can keep dust aloft, increasing exposure risks. Still air, conversely, allows particles to settle more rapidly. A study found that in a room with air movement at 0.5 meters per second, 5-μm wood particles remained suspended for over 24 hours, while in still air, they settled within 6 hours.

Humidity and Temperature: Silent Influencers

High humidity causes wood dust particles to absorb moisture, increasing their mass and accelerating settling. At 80% relative humidity, 10-μm particles settle 30% faster than at 40% humidity. Temperature also plays a role: warmer air reduces particle settling by decreasing air density, while cooler air promotes settling. For instance, dust in a 20°C workshop settles more slowly than in a 10°C environment.

Practical Tips for Control

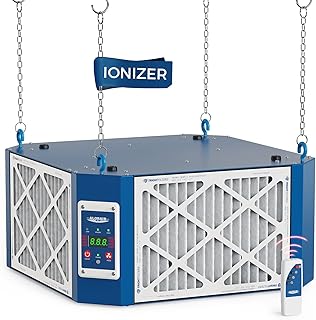

To minimize suspension time, use dust extraction systems with filters rated for fine particles (e.g., HEPA filters capturing 99.97% of particles ≥0.3 μm). Keep air movement controlled—avoid fans that disperse dust and seal windows during high-dust operations. Maintain optimal humidity (40–60%) to prevent particle clumping without prolonging suspension. Regularly clean surfaces to prevent re-entrainment of settled dust into the air.

By addressing these factors systematically, woodworkers can reduce airborne dust exposure, creating safer and healthier workspaces.

How Long Does Spider Wood Take to Sink in Aquariums?

You may want to see also

Explore related products

$400.57 $499.99

Particle size impact on airborne duration

Wood dust particles vary widely in size, typically ranging from 0.1 to 100 micrometers (μm). This size directly influences how long they remain suspended in the air. Larger particles, such as those exceeding 10 μm, are heavier and settle quickly, often within minutes. In contrast, finer particles under 5 μm can stay airborne for hours or even days, posing a greater inhalation risk. Understanding this size-based behavior is critical for assessing exposure risks in woodworking environments.

Consider a practical scenario: sanding a wooden surface generates a mix of particle sizes. Coarse dust accumulates on nearby surfaces almost immediately, while finer particles linger, creating a persistent hazard. To mitigate this, use HEPA filtration systems, which capture particles as small as 0.3 μm with 99.97% efficiency. Additionally, wet sanding or misting techniques reduce particle dispersion by binding dust to water droplets, effectively increasing particle size and accelerating settling.

The health implications of particle size cannot be overstated. Particles under 2.5 μm (PM2.5) can penetrate deep into the lungs, while ultrafine particles (<0.1 μm) may enter the bloodstream. Prolonged exposure to such sizes increases the risk of respiratory diseases, including asthma and chronic bronchitis. For workers, wearing N95 respirators, which filter out 95% of particles ≥0.3 μm, is essential. Regular air quality monitoring with particle counters can identify size distributions, enabling targeted control measures.

Comparing wood dust to other airborne contaminants highlights its unique challenges. For instance, silica dust, often larger and denser, settles faster than fine wood particles. This distinction underscores the need for wood-specific control strategies. Unlike chemical fumes, which disperse uniformly, wood dust concentration varies with particle size and airflow patterns. Thus, localized exhaust ventilation, positioned close to the dust source, is more effective than general room ventilation for capturing larger particles before they settle.

In summary, particle size dictates airborne duration and health risks associated with wood dust. Larger particles settle swiftly, while finer ones persist, requiring tailored control measures. Implementing HEPA filtration, wet methods, and proper respiratory protection addresses size-specific hazards. By focusing on particle size, workplaces can significantly reduce exposure, safeguarding both short-term and long-term health.

Durability Unveiled: Understanding the Lifespan of Wooden Gates

You may want to see also

Explore related products

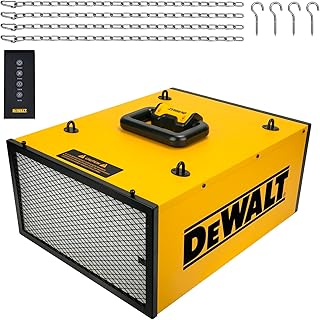

$126.35 $144.99

Airflow and ventilation effects on dust

Wood dust particles, typically ranging from 1 to 100 micrometers in size, behave differently in the air depending on airflow and ventilation. Larger particles (50+ micrometers) settle quickly due to gravity, often within minutes, while finer particles (<10 micrometers) can remain suspended for hours or even days. This distinction is critical because finer particles are more likely to penetrate deep into the respiratory system, posing health risks like asthma, bronchitis, or, in extreme cases, lung cancer. Understanding how airflow and ventilation influence particle dispersion is key to mitigating these risks.

Effective ventilation systems can drastically reduce wood dust concentration by diluting and removing particles from the air. For instance, a well-designed exhaust system with a capture velocity of 2,000 feet per minute (fpm) near the dust source can prevent particles from dispersing widely. In contrast, poor ventilation or turbulent airflow can stir up settled dust, increasing airborne time and exposure. OSHA recommends maintaining airborne wood dust levels below 5 mg/m³ as an 8-hour time-weighted average (TWA) for employee safety. Achieving this requires not only proper ventilation but also strategic airflow management to direct dust toward collection points.

In workspaces like woodworking shops, airflow patterns should be engineered to minimize dust recirculation. For example, placing intake vents low and exhaust vents high creates a natural convection current that pulls dust downward and outward. HEPA filters in ventilation systems can capture 99.97% of particles 0.3 micrometers or larger, ensuring that even fine dust is removed. However, filters must be regularly maintained to prevent clogging, which reduces airflow efficiency and allows dust to accumulate.

For DIY enthusiasts or small workshops, practical steps include using local exhaust ventilation (LEV) tools like dust collectors with cyclone separators, which can remove up to 90% of wood dust before it becomes airborne. Positioning fans to direct airflow away from breathing zones and toward open windows or exhaust points can also help. A simple rule of thumb: if you can see dust lingering in a beam of light, your ventilation is inadequate. Immediate action, such as increasing airflow or using a portable air purifier, can reduce exposure risks.

In summary, airflow and ventilation are not just about moving air but about controlling dust behavior. By optimizing these factors, you can significantly reduce the time wood dust stays airborne, protecting both health and workspace cleanliness. Whether in a professional setting or a home garage, understanding and applying these principles is essential for safe wood dust management.

Engineered Wood Span: Understanding Maximum Lengths and Structural Limits

You may want to see also

Explore related products

Humidity influence on wood dust settling

Wood dust particles, typically ranging from 1 to 100 micrometers in size, exhibit varying behavior in the air depending on humidity levels. At low humidity (below 30%), wood dust remains lighter and more suspended due to reduced moisture absorption, which keeps particles dry and less likely to clump. Conversely, in high-humidity environments (above 60%), particles absorb moisture, increasing their mass and accelerating settling rates. This relationship is critical in workplaces like sawmills or carpentry shops, where humidity control can directly impact airborne dust concentrations and respiratory risks.

To mitigate wood dust exposure, consider these actionable steps: maintain indoor humidity between 40% and 50% using dehumidifiers or humidifiers, depending on your climate. For example, in a woodworking shop, a hygrometer can monitor humidity levels, and a portable dehumidifier can reduce moisture to optimal ranges. Additionally, install local exhaust ventilation near dust-generating tools to capture particles before they disperse. Regularly clean surfaces with a damp cloth to prevent dust recirculation, and ensure workers wear N95 respirators in areas where dust levels exceed OSHA’s permissible exposure limit of 5 mg/m³ for wood dust.

Comparing low- and high-humidity scenarios reveals distinct advantages and challenges. In dry conditions, dust remains airborne longer, increasing inhalation risks but simplifying cleanup as particles settle slowly. In contrast, high humidity speeds settling, reducing airborne exposure but creating slippery, dust-laden surfaces that require frequent maintenance. For instance, a study in a humid tropical workshop found that wood dust settled 30% faster than in a dry desert environment, but workers reported more frequent floor cleaning to prevent hazards.

From a persuasive standpoint, controlling humidity isn’t just about compliance—it’s about protecting health and productivity. Prolonged exposure to wood dust, especially in humid conditions, can lead to respiratory issues like asthma or, in extreme cases, nasal cancer. By investing in humidity control systems and proper ventilation, employers can reduce absenteeism, lower healthcare costs, and foster a safer work environment. For example, a Canadian sawmill reduced worker complaints of respiratory irritation by 40% after implementing a humidity-controlled dust management plan.

Finally, understanding the interplay between humidity and wood dust settling allows for tailored solutions. In arid regions, focus on preventing dust suspension by using water misting systems near cutting areas. In humid climates, prioritize surface cleaning and anti-slip measures to manage settled dust. For instance, a furniture factory in a humid coastal area reduced dust-related accidents by 25% after introducing daily floor treatments with dust-binding agents. By addressing humidity’s role, you can create a safer, more efficient workspace tailored to your specific conditions.

Evan Rachel Wood and Justin Long: Did They Date?

You may want to see also

Explore related products

Dust control methods to reduce airborne time

Wood dust particles, ranging from 1 to 100 microns, can remain suspended in the air for minutes to hours, depending on size, air currents, and ventilation. Smaller particles, under 10 microns, pose the greatest health risk as they penetrate deep into the lungs and are slow to settle. Effective dust control methods are essential to minimize airborne time and protect workers from respiratory hazards like asthma, bronchitis, and even lung cancer.

Engineering controls form the backbone of dust reduction strategies. Local exhaust ventilation (LEV) systems, such as hoods and ducts, capture dust at its source before it disperses. For woodworking machinery, ensure LEV systems are properly designed with adequate airflow—typically 2,000–4,000 cubic feet per minute (cfm) for table saws and 1,000–2,000 cfm for sanders. Regularly inspect and clean ducts to prevent blockages, as even a 20% reduction in airflow can significantly decrease efficiency.

Administrative controls complement engineering solutions by altering work practices. Wet methods, like using water-based sprays during cutting or sanding, suppress dust formation. For example, applying a mist of water at 30–50 psi to the cutting blade reduces airborne particles by up to 90%. Additionally, schedule high-dust tasks during periods of low occupancy and limit exposure time to 15–30 minutes per hour, followed by breaks in clean air zones.

Personal protective equipment (PPE) serves as a last line of defense. Respirators with N95 or P100 filters are effective for particles under 2.5 microns, but ensure workers are fit-tested and trained. Disposable masks should be replaced daily or when breathing resistance increases. For prolonged tasks, powered air-purifying respirators (PAPRs) offer higher comfort and protection, especially in environments with dust concentrations exceeding 10 mg/m³.

Combining these methods creates a layered defense, drastically reducing wood dust’s airborne time. For instance, a workshop using LEV, wet cutting, and respirators can cut particle suspension time by 75%, from hours to mere minutes. Regular monitoring with real-time dust meters ensures compliance with OSHA’s permissible exposure limit of 5 mg/m³ for wood dust, safeguarding both health and productivity.

Understanding Wood Decay: Factors Influencing Decomposition and Longevity

You may want to see also

Frequently asked questions

Wood dust can remain suspended in the air for several hours, depending on factors like particle size, air movement, and ventilation. Finer particles may stay airborne longer, while larger particles settle more quickly.

Yes, wood dust will eventually settle on surfaces, typically within a few hours to a day. However, fine particles may remain airborne longer and require proper ventilation or air filtration to clear.

Yes, settled wood dust can become airborne again if disturbed by movement, cleaning, or air currents. Using damp cleaning methods and proper dust control measures can prevent recirculation.