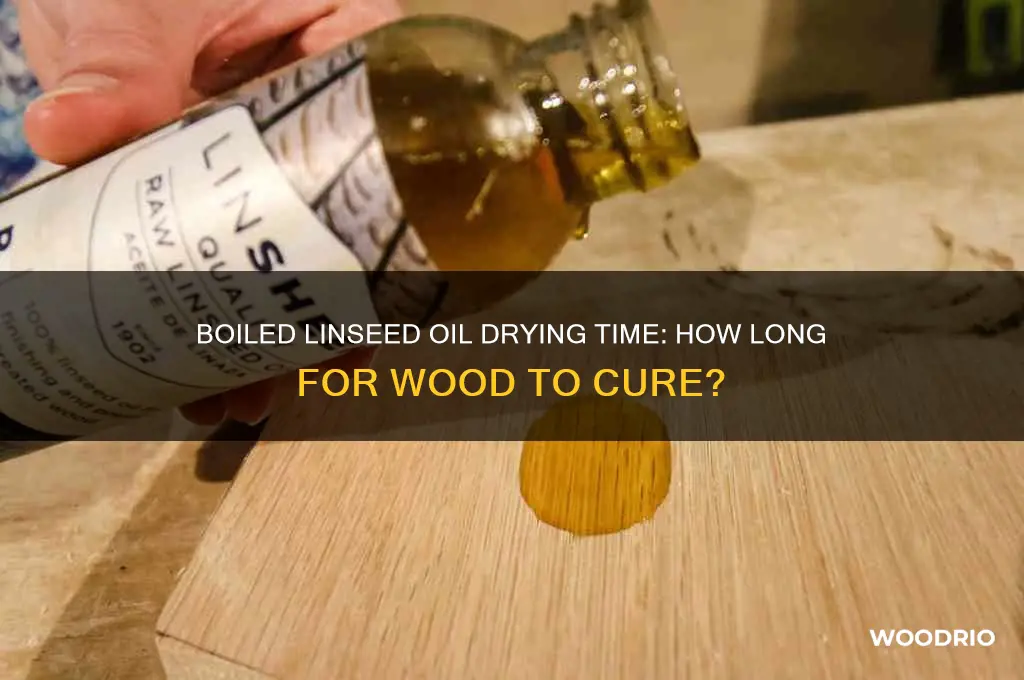

Boiled linseed oil is a popular wood finish known for its ability to enhance the natural beauty of wood while providing protection. However, one common question among woodworkers and DIY enthusiasts is how long it takes for boiled linseed oil to dry on wood. The drying time can vary depending on several factors, including the humidity, temperature, and the thickness of the oil application. Generally, boiled linseed oil can take anywhere from 24 to 72 hours to dry to the touch, but it may require additional time, up to a week or more, to fully cure and reach its maximum hardness. Understanding these variables is crucial for achieving the desired finish and ensuring the longevity of the treated wood.

| Characteristics | Values |

|---|---|

| Drying Time (Surface Dry) | 2-8 hours (depending on humidity, temperature, and wood porosity) |

| Drying Time (Touch Dry) | 8-24 hours |

| Full Cure Time | 7-15 days (for maximum hardness and durability) |

| Factors Affecting Drying Time | Humidity, temperature, wood type, thickness of application, ventilation |

| Optimal Drying Conditions | 70-75°F (21-24°C), low humidity, good airflow |

| Reapplication Time | 24-48 hours after initial coat (if additional coats are needed) |

| Accelerating Drying | Use heat lamps, fans, or heaters (with caution to avoid overheating) |

| Sanding Between Coats | Light sanding after 24 hours (if necessary) |

| Durability After Full Cure | Provides a hard, protective finish resistant to moisture and wear |

| Odor During Drying | Mild linseed oil scent (non-toxic but well-ventilated area recommended) |

Explore related products

What You'll Learn

Temperature Impact on Drying Time

Temperature plays a pivotal role in determining how quickly boiled linseed oil dries on wood, with warmer conditions accelerating the process and cooler temperatures slowing it down. At 70°F (21°C) and above, boiled linseed oil typically dries to the touch within 4 to 6 hours and fully cures in 24 to 48 hours. However, at 50°F (10°C), drying time can extend to 8 hours for touch dryness and up to 72 hours for full curing. Below 50°F, the oil may remain tacky indefinitely, as the chemical reactions necessary for drying are severely hindered. This sensitivity to temperature makes it essential to plan application during optimal weather conditions or in controlled environments.

To maximize efficiency, consider the following steps when applying boiled linseed oil in varying temperatures. In warmer climates, apply thin coats to prevent the oil from drying too quickly and leaving uneven patches. For cooler environments, use a hairdryer or heat gun on low settings to gently warm the surface after application, but avoid overheating, which can damage the wood. If working indoors, maintain a consistent temperature of at least 65°F (18°C) for best results. Always allow for adequate ventilation to aid evaporation, regardless of temperature.

A comparative analysis reveals that temperature not only affects drying time but also the quality of the finish. In warmer conditions, the oil penetrates deeper into the wood fibers, enhancing durability and richness of color. Cooler temperatures, however, can lead to a surface-level finish that may be less resilient to wear and tear. For outdoor projects, aim for application during mild, dry days with temperatures between 60°F and 80°F (15°C to 27°C) to balance drying speed and finish quality. Avoid applying boiled linseed oil in direct sunlight, as rapid drying can cause blotching or uneven absorption.

For those in colder climates, a persuasive argument can be made for using additives to improve drying times. Mixing boiled linseed oil with a solvent like mineral spirits (in a 3:1 oil-to-solvent ratio) can reduce viscosity and enhance penetration, even in cooler temperatures. Alternatively, consider using a commercial linseed oil product with added dryers, which are metallic salts that accelerate curing. However, be cautious with additives, as they may alter the natural properties of the oil or pose health risks if not handled properly. Always wear gloves and work in a well-ventilated area when using modified products.

In conclusion, understanding the temperature impact on drying time is crucial for achieving a flawless finish with boiled linseed oil. By adjusting application techniques, choosing optimal conditions, and considering additives when necessary, you can ensure the oil dries efficiently and effectively, regardless of the climate. Whether working on indoor furniture or outdoor decking, temperature control is a key factor in mastering this traditional wood finishing technique.

Drying Wood Chips: Understanding the Timeframe for Optimal Results

You may want to see also

Explore related products

Humidity Effects on Oil Curing

Humidity plays a pivotal role in the curing time of boiled linseed oil on wood, often dictating whether the finish sets to a smooth, durable sheen or remains tacky and underwhelming. At 50% relative humidity and 70°F (21°C), boiled linseed oil typically reaches a dry-to-touch state within 6–8 hours and fully cures in 24–48 hours. However, as humidity climbs above 70%, curing time can double or even triple due to reduced evaporation rates of the oil’s solvent carriers. Conversely, in arid conditions below 30% humidity, the oil may dry too quickly, leading to an uneven, blotchy finish. Understanding this relationship is critical for achieving optimal results, especially in environments with fluctuating moisture levels.

To mitigate humidity’s impact, consider these practical steps: First, apply boiled linseed oil in thin, even coats using a natural-bristle brush or lint-free cloth, as over-application exacerbates curing issues in humid conditions. Second, maintain a consistent temperature between 65°F and 75°F (18°C–24°C) to balance evaporation and oxidation rates. Third, use a dehumidifier or fan to reduce ambient moisture, particularly in basements or during rainy seasons. For outdoor projects, schedule application during dry, mild weather and avoid evenings when dew points rise. Lastly, if humidity is unavoidable, extend curing time by lightly sanding the surface after 48 hours and applying a second coat to ensure proper polymerization.

The science behind humidity’s effect lies in its interference with the oil’s oxidation process. Boiled linseed oil contains metallic dryers (typically manganese) that accelerate curing by reacting with oxygen. High humidity creates a moisture barrier, slowing oxygen absorption and delaying polymerization. In contrast, low humidity accelerates solvent evaporation, leaving the oil’s binders to cure too rapidly, often resulting in a brittle finish. This delicate balance underscores why woodworkers in humid climates, such as coastal regions, often prefer alternative finishes like tung oil, which cures via polymerization alone and is less humidity-sensitive.

A comparative analysis reveals that while boiled linseed oil is prized for its durability and rich patina, its humidity dependency makes it less forgiving than modern finishes. Polyurethane, for instance, cures via a chemical reaction unaffected by moisture, making it a reliable choice in damp environments. However, for those committed to the natural aesthetic of linseed oil, strategic timing and environmental control can yield superior results. For example, applying oil during the dry hours of midday and using a moisture meter to ensure wood humidity below 12% can significantly improve curing efficiency.

In conclusion, mastering the interplay between humidity and boiled linseed oil requires both patience and precision. By monitoring environmental conditions, adjusting application techniques, and allowing ample curing time, woodworkers can harness the oil’s beauty while minimizing its drawbacks. Whether restoring antique furniture or finishing a new project, recognizing humidity’s role ensures a finish that not only looks stunning but also stands the test of time.

Wood Decomposition Timeline: Factors Affecting Breakdown and Decay Process

You may want to see also

Explore related products

Oil Application Thickness Influence

The thickness of your boiled linseed oil application directly impacts drying time, with thicker coats taking significantly longer to cure. This is because thicker layers restrict oxygen flow, hindering the oxidation process crucial for drying. While a thin coat might dry within 24 hours under ideal conditions, a heavy application can take several days, even weeks, to fully cure.

Understanding this relationship is key to achieving a durable and aesthetically pleasing finish.

Imagine applying a thin, even coat of boiled linseed oil to a wooden tabletop. This allows oxygen to penetrate the oil, promoting rapid oxidation and a relatively quick drying time. Conversely, slathering on a thick layer creates a barrier, slowing down the drying process and potentially leading to a sticky, uneven finish.

Think of it like painting a wall: thin, even coats dry faster and smoother than thick, globby ones.

For optimal results, aim for a thin, uniform application. Use a clean, lint-free cloth or brush to apply a generous but controlled amount of oil. Wipe away any excess immediately to prevent pooling and ensure a consistent thickness. Remember, multiple thin coats are always preferable to a single thick one. This layered approach allows each coat to dry properly, resulting in a deeper penetration of the oil and a more durable finish.

As a general guideline, allow at least 24 hours of drying time between coats, sanding lightly with fine-grit sandpaper before applying the next layer.

While thicker applications might seem like a time-saver, they often lead to frustration and unsatisfactory results. The prolonged drying time increases the risk of dust and debris settling on the surface, marring the finish. Additionally, thick coats are more prone to cracking and peeling as the wood expands and contracts with changes in humidity. By embracing the "thin and patient" approach, you'll achieve a beautiful, long-lasting finish that showcases the natural beauty of the wood.

Varnish Drying Time on Wood: Factors Affecting Cure Duration

You may want to see also

Explore related products

Accelerating Drying with Heat Sources

Heat can significantly accelerate the drying time of boiled linseed oil on wood, but its application requires careful consideration to avoid damaging the wood or finish. The drying process of linseed oil is a chemical reaction known as polymerization, which is temperature-dependent. At room temperature (around 70°F or 21°C), boiled linseed oil typically takes 8–24 hours to dry to the touch and up to 72 hours for a full cure. Applying heat can reduce these times by up to 50%, but improper use can lead to uneven drying, blistering, or discoloration.

To effectively use heat, start by ensuring the wood surface is clean, dry, and evenly coated with a thin layer of boiled linseed oil. Thicker applications will take longer to dry and are more prone to issues when heat is applied. Use a heat source such as a heat gun, hairdryer, or infrared lamp, maintaining a distance of 6–12 inches from the surface. Move the heat source continuously to avoid overheating any single area. Aim for a surface temperature of 100–120°F (38–49°C), which can be monitored with a non-contact infrared thermometer. Exceeding this range risks scorching the wood or oil.

While heat accelerates drying, it does not replace proper ventilation. Ensure the workspace is well-ventilated to allow solvent evaporation, a critical part of the drying process. Combining heat with a fan can enhance evaporation while dispersing heat evenly. For larger projects, consider using a heated workspace or tent to maintain consistent warmth without direct heat application. However, avoid using open flames or high-temperature sources, as they pose fire risks and can degrade the oil’s properties.

A practical tip is to apply heat in stages, especially for multiple coats. After the first coat dries to the touch (typically 4–6 hours with heat), lightly sand the surface with 220-grit sandpaper to improve adhesion before applying the next coat. Repeat the heating process for subsequent layers, ensuring each coat is fully dry before proceeding. This method not only speeds up drying but also enhances the finish’s durability and appearance.

In conclusion, heat is a powerful tool for accelerating the drying of boiled linseed oil on wood, but it demands precision and caution. By controlling temperature, maintaining ventilation, and applying heat evenly, you can achieve a faster, more consistent finish without compromising quality. Always test on a small area first to ensure compatibility with your wood type and desired outcome.

Charcoal vs. Wood: Which Burns Longer for Your Fire Needs?

You may want to see also

Explore related products

Comparing Boiled vs. Raw Linseed Oil

Boiled linseed oil and raw linseed oil are both derived from flaxseeds, but their drying times and properties differ significantly due to processing methods. Boiled linseed oil contains metallic dryers that accelerate curing, typically drying to the touch within 8–12 hours and fully curing in 24–48 hours under ideal conditions. Raw linseed oil, lacking these additives, can take 2–7 days to dry to the touch and up to several weeks to fully cure, depending on humidity and temperature. This disparity makes boiled linseed oil a preferred choice for projects requiring quicker turnaround times.

The application process for these oils also varies. Boiled linseed oil penetrates wood more rapidly, making it ideal for sealing and finishing projects where time is a constraint. Raw linseed oil, while slower, offers deeper penetration over time, enhancing the wood’s natural grain without darkening it as much as its boiled counterpart. For best results, apply both oils thinly with a brush or cloth, wiping off excess to avoid sticky surfaces. Multiple coats may be necessary, allowing ample drying time between applications.

One critical distinction lies in their suitability for specific projects. Boiled linseed oil is better for outdoor furniture, decks, or flooring due to its faster drying time and added durability. Raw linseed oil, being free of metallic dryers, is safer for food-contact surfaces like cutting boards or salad bowls, though it requires patience during application. Always ensure proper ventilation when working with either product, as both release volatile organic compounds (VOCs) during drying.

A practical tip for accelerating raw linseed oil drying is to warm the wood surface slightly before application, as heat aids absorption. Conversely, avoid applying boiled linseed oil in direct sunlight or high heat, as this can cause uneven drying or surface tackiness. For both oils, sanding between coats with fine-grit sandpaper ensures smoother finishes. Understanding these nuances allows woodworkers to choose the right oil for their project’s timeline and purpose.

Durability Unveiled: Lifespan of Composition Wood Siding Explained

You may want to see also

Frequently asked questions

Boiled linseed oil typically takes 24 to 48 hours to dry to the touch, but it can take 7 to 14 days to fully cure, depending on humidity, temperature, and wood type.

Yes, warmer temperatures (70°F to 80°F or 21°C to 27°C) accelerate drying, while cooler or humid conditions can significantly slow it down, extending drying time to several days or more.

Yes, you can speed up drying by ensuring good ventilation, using a fan, or applying heat gently. However, avoid excessive heat, as it can cause uneven drying or damage the wood.

The oil is fully cured when the wood no longer feels tacky or oily to the touch, and it has a consistent, matte or satin finish. Test a small area to ensure it’s completely dry before applying additional coats or using the wood.

![Chelsea Classical Studio Linseed Oil Paint Medium - Cold Pressed Extra Pale Naturally Clarified De-Yellowed by Natural Processed Linseed Oil - [2 oz. Bottle]](https://m.media-amazon.com/images/I/61s773Hu-EL._AC_UL320_.jpg)