Green wood cremation, an eco-friendly alternative to traditional cremation, involves the use of untreated, natural wood to create a sustainable and biodegradable urn or container for ashes. When considering how long the process takes, it’s important to note that the duration depends on factors such as the type of wood, its moisture content, and the cremation method used. Typically, green wood cremation can take anywhere from 2 to 4 hours, similar to conventional cremation, but the focus remains on minimizing environmental impact by avoiding harsh chemicals and utilizing renewable materials. This method appeals to those seeking a more earth-conscious way to honor their loved ones while reducing their carbon footprint.

| Characteristics | Values |

|---|---|

| Cremation Time for Green Wood | 2-4 hours (varies based on wood type, moisture content, and kiln size) |

| Moisture Content of Green Wood | 40-60% (significantly higher than seasoned wood at 20%) |

| Temperature Required | 1400-1600°F (760-871°C) |

| Energy Consumption | 2-3 times higher than seasoned wood cremation |

| Emissions | Higher due to moisture evaporation and longer burn time |

| Ash Volume | Less compared to seasoned wood due to higher moisture loss |

| Common Wood Types | Pine, fir, spruce, and other softwoods |

| Pre-Drying Requirement | Often necessary to reduce moisture content before cremation |

| Environmental Impact | Higher carbon footprint due to increased energy use |

| Cost | Higher due to longer processing time and energy consumption |

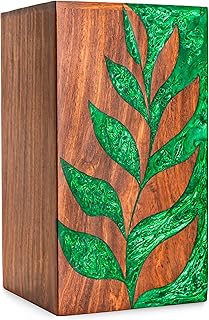

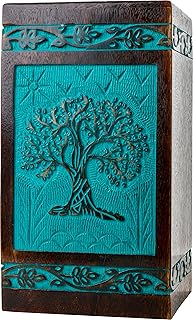

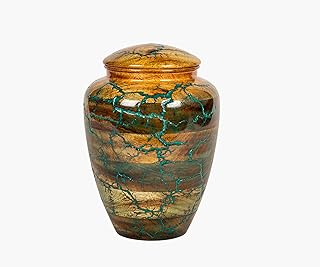

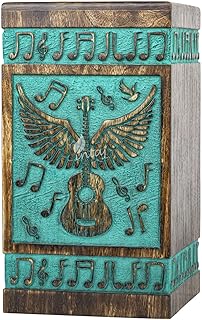

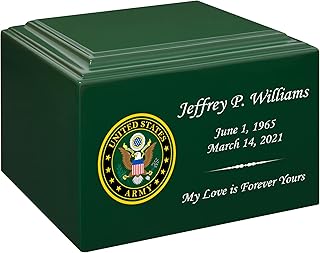

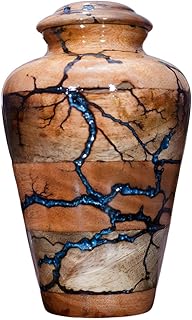

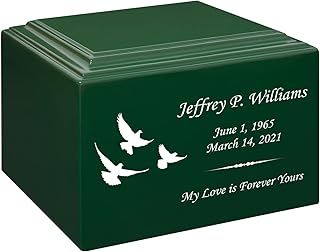

Explore related products

What You'll Learn

Drying Time Requirements

Green wood, freshly cut and still retaining its natural moisture, poses a unique challenge in cremation processes. The presence of water significantly impacts the efficiency and duration of cremation, making drying time a critical factor. Unlike seasoned wood, which has been air-dried to reduce moisture content, green wood can contain up to 50% water by weight. This high moisture level necessitates additional time and energy to evaporate the water before the wood can effectively combust. Understanding the drying time requirements is essential for optimizing cremation procedures and ensuring complete and efficient results.

From a practical standpoint, drying green wood before cremation involves a systematic approach. The first step is to assess the moisture content, which can be done using a moisture meter. For cremation purposes, the ideal moisture content should be below 20%. To achieve this, green wood can be air-dried in a well-ventilated area, protected from rain, and elevated off the ground to prevent moisture absorption. This process can take anywhere from several weeks to several months, depending on factors such as humidity, temperature, and wood density. For faster results, kiln drying is an option, reducing drying time to days but requiring specialized equipment and energy input.

A comparative analysis reveals that the drying time for green wood cremation is not just a matter of convenience but also of environmental and economic impact. Air drying, while cost-effective and energy-efficient, demands significant time and space, making it less feasible for large-scale operations. Kiln drying, on the other hand, accelerates the process but consumes more energy, increasing operational costs and carbon footprint. Additionally, the type of wood plays a role; softer woods like pine dry faster than denser hardwoods like oak. Balancing these factors is crucial for facilities aiming to minimize both time and resource expenditure.

Persuasively, investing in proper drying techniques for green wood cremation yields long-term benefits. Incomplete drying can lead to prolonged cremation times, higher fuel consumption, and even equipment strain due to the energy required to evaporate excess moisture. Moreover, improperly dried wood may result in incomplete combustion, leaving behind residual material that requires additional processing. By prioritizing adequate drying, cremation facilities can enhance operational efficiency, reduce costs, and maintain environmental sustainability. Practical tips include stacking wood in single rows to maximize air circulation and using moisture meters to monitor progress regularly.

In conclusion, drying time requirements for green wood cremation are a critical yet often overlooked aspect of the process. Whether through air drying or kiln drying, achieving the optimal moisture content is essential for efficient combustion. Facilities must weigh the trade-offs between time, cost, and environmental impact when choosing a drying method. By adopting best practices and understanding the nuances of wood moisture management, cremation providers can ensure smoother operations and better outcomes. This attention to detail not only streamlines the cremation process but also aligns with broader goals of sustainability and resource conservation.

Minwax Wood Filler Drying Time: Quick Guide for Perfect Results

You may want to see also

Explore related products

Cremation Process Duration

The duration of a cremation process, particularly for green wood, hinges on several factors, including the type of wood, its moisture content, and the efficiency of the cremation unit. Green wood, which retains a higher moisture level compared to seasoned wood, typically requires a longer cremation time due to the energy needed to evaporate the water before combustion can occur. This process can extend the cremation time by 30% to 50% compared to drier materials, often ranging from 3 to 5 hours instead of the standard 2 to 3 hours for seasoned wood or other materials.

To optimize the cremation process for green wood, pre-drying the material can significantly reduce the overall duration. This can be achieved by air-drying the wood for several weeks or using a kiln to expedite the process. For instance, kiln-drying green wood for 48 to 72 hours at 120°F to 140°F can reduce its moisture content from 50% to below 20%, making it more suitable for cremation. This preparatory step not only shortens the cremation time but also ensures a more consistent and efficient burn.

Another critical factor is the cremation unit’s design and capacity. Modern cremators equipped with advanced combustion technology and secondary chambers for afterburning can handle green wood more effectively. These units often feature programmable controls that adjust temperature and airflow based on the material’s moisture content, ensuring a thorough and timely cremation. For example, units with a capacity of 1,500°F to 2,000°F can process green wood more efficiently than older models, reducing the risk of incomplete combustion or excessive fuel consumption.

Practical tips for managing green wood cremation include selecting wood with a lower initial moisture content, such as softwoods like pine, which dry faster than hardwoods like oak. Additionally, breaking the wood into smaller pieces increases the surface area, allowing for faster drying and more uniform combustion. Cremation operators should also monitor the process closely, adjusting settings as needed to maintain optimal conditions. For instance, increasing the air supply during the initial phase can help evaporate moisture more quickly, while reducing it during the final stages ensures complete combustion without wasting energy.

In conclusion, while green wood cremation inherently takes longer than that of drier materials, strategic preparation and the use of advanced equipment can mitigate delays. By pre-drying the wood, selecting appropriate types, and leveraging modern cremator technology, operators can achieve efficient and timely cremations. Understanding these variables allows for better planning and resource management, ensuring a respectful and environmentally conscious process.

Drying Wood Slabs: Essential Tips for Perfect Moisture Levels

You may want to see also

Explore related products

Moisture Impact on Burning

Green wood, often referred to as "wet" or "unseasoned" wood, contains a significant amount of moisture, typically ranging from 30% to 200% of its dry weight, depending on the species and freshness. This moisture acts as a heat sink during combustion, absorbing thermal energy that would otherwise be used to sustain the burning process. As a result, green wood requires substantially more time and energy to reach ignition temperature (approximately 572°F or 300°C) compared to seasoned wood, which has a moisture content below 20%. For cremation purposes, this delay translates to longer burn times, often exceeding 4 to 6 hours, versus the 2 to 3 hours typical for dry wood.

To mitigate the impact of moisture, pre-drying green wood is essential. Air-drying for 6 to 12 months reduces moisture content to manageable levels, while kiln-drying accelerates this process to weeks. However, in cremation scenarios, such preparation is rarely feasible. Instead, practitioners must account for the prolonged burn time by using larger fuel quantities or supplemental heat sources. For instance, adding 50% more green wood by volume or incorporating dry kindling can help maintain consistent combustion. Caution is advised, though, as excessive moisture can lead to incomplete burning, leaving behind uncremated material or increasing particulate emissions.

The science behind moisture’s effect on burning lies in the phase-change energy required to convert water from liquid to vapor. For every kilogram of water evaporated, approximately 2,260 kJ of energy is consumed—energy that does not contribute to raising the wood’s temperature. This inefficiency is compounded in cremation, where uniform heat distribution is critical. Moisture pockets within the wood create uneven burning, potentially leaving cooler zones that hinder complete combustion. To counteract this, periodic turning of the material or forced air circulation can improve heat penetration, though these methods add complexity to the process.

Practically, understanding moisture’s role allows for better planning and resource allocation. For small-scale cremations, such as pet or ceremonial burns, using green wood is feasible but requires patience and vigilance. Monitoring the fire’s progress and adjusting fuel placement every 30 to 60 minutes ensures steady combustion. For larger-scale operations, green wood is generally discouraged due to its inefficiency and environmental drawbacks, including higher smoke production and increased fuel consumption. In all cases, prioritizing dry wood remains the most reliable approach, but when green wood is the only option, acknowledging and adapting to its moisture content is key to success.

Cedar Wood Deck Lifespan: Durability, Maintenance, and Longevity Explained

You may want to see also

Explore related products

Fuel Efficiency Factors

The duration of green wood cremation is significantly influenced by fuel efficiency, a factor often overlooked in favor of more obvious variables like wood moisture content. Efficient fuel usage not only reduces cremation time but also minimizes environmental impact and operational costs. Understanding the key elements that affect fuel efficiency can help optimize the process, ensuring both effectiveness and sustainability.

Combustion Chamber Design plays a pivotal role in fuel efficiency. A well-insulated chamber retains heat more effectively, reducing the need for continuous fuel input. Modern cremation units often incorporate refractory materials with high thermal resistance, such as ceramic fiber boards, which can withstand temperatures up to 1,800°F (982°C). These materials minimize heat loss, allowing the chamber to maintain optimal combustion temperatures with less fuel. For instance, a unit with 4 inches of ceramic insulation can reduce fuel consumption by up to 20% compared to less insulated models.

Airflow Control is another critical factor. Proper oxygen supply ensures complete combustion, preventing the formation of smoke and unburned particles that waste fuel. Cremation units equipped with adjustable air dampers allow operators to fine-tune airflow based on the wood’s moisture content. For green wood, which typically contains 40-60% moisture, a higher initial airflow rate (e.g., 200 cubic feet per minute) can help drive off moisture faster, followed by a reduction to 100 cubic feet per minute for efficient combustion of dry wood. This staged approach maximizes fuel efficiency while minimizing cremation time.

Fuel Type and Quality also impact efficiency. Natural gas is the most efficient fuel for cremation, with a combustion efficiency of up to 90%, compared to 70-80% for propane. However, the availability and cost of natural gas vary by region, making propane a viable alternative. Regardless of fuel type, ensuring a consistent supply pressure (e.g., 7 inches water column for natural gas) is essential to maintain optimal combustion. Contaminants in fuel, such as rust or debris, can clog burners and reduce efficiency, so regular maintenance of fuel lines and filters is crucial.

Operator Practices can further enhance fuel efficiency. Pre-drying green wood in a solar kiln or dehumidified environment reduces its moisture content, decreasing the energy required for cremation. For example, reducing wood moisture from 50% to 30% can shorten cremation time by 25-30%. Additionally, operators should avoid overloading the cremation chamber, as this restricts airflow and increases fuel consumption. A general rule is to fill the chamber to no more than 75% of its capacity, ensuring adequate space for air circulation.

By addressing these fuel efficiency factors—combustion chamber design, airflow control, fuel type and quality, and operator practices—cremation facilities can significantly reduce the time required for green wood cremation while lowering fuel costs and environmental impact. Implementing these strategies not only streamlines operations but also aligns with sustainable practices in an industry increasingly focused on reducing its carbon footprint.

Durability of Wolmanized Wood: Lifespan and Longevity Explained

You may want to see also

Explore related products

Safety Precautions for Green Wood

Green wood, with its higher moisture content, poses unique challenges during cremation, making safety precautions essential. Unlike seasoned wood, green wood requires longer burn times, increasing the risk of incomplete combustion and excessive smoke. This not only prolongs the cremation process but also heightens the potential for hazardous emissions, including carbon monoxide and particulate matter. Crematorium operators must account for these factors to ensure both efficiency and safety.

Step 1: Moisture Assessment and Preparation

Before cremation, assess the moisture content of the green wood. A moisture meter can provide precise readings, ideally below 20% for safer combustion. If the wood exceeds this threshold, consider kiln-drying or air-drying it for several weeks. For immediate use, pre-drying the wood in a controlled environment can reduce moisture levels, minimizing the risk of excessive smoke and prolonged burn times.

Step 2: Controlled Combustion Techniques

When cremating green wood, start with a low-temperature burn to gradually release moisture without causing flare-ups. Gradually increase the temperature to ensure thorough combustion. Use a cremator with adjustable settings to maintain control over the process. Avoid overloading the chamber, as this can lead to uneven burning and increased safety risks.

Caution: Ventilation and Emission Monitoring

Proper ventilation is critical when cremating green wood. Ensure the crematorium’s exhaust system is functioning optimally to expel smoke and harmful gases. Install carbon monoxide and particulate matter detectors to monitor emissions in real-time. If levels exceed safety thresholds (e.g., CO levels above 35 ppm), halt the process and address the issue before proceeding.

Practical Tip: Post-Cremation Cleanup

After cremation, inspect the chamber for residual ash or unburned wood, as green wood can leave behind more debris than seasoned wood. Thoroughly clean the chamber to prevent buildup, which can affect future cremations and pose fire hazards. Regular maintenance of the cremator’s filters and exhaust system is equally vital to ensure long-term safety.

By implementing these safety precautions, crematorium operators can mitigate the risks associated with green wood cremation, ensuring a safer and more efficient process. Attention to moisture levels, controlled combustion, and vigilant monitoring are key to addressing the unique challenges posed by green wood.

Buffalo's Wood Fence Lifespan: Factors Affecting Durability in Harsh Winters

You may want to see also

Frequently asked questions

The cremation process for green wood typically takes longer than for dry wood, ranging from 3 to 6 hours, depending on the moisture content and the size of the wood.

Yes, the moisture in green wood significantly increases cremation time because the heat must first evaporate the water before the wood can combust and ash properly.

Yes, green wood can be cremated in a standard unit, but it requires more energy and time due to the moisture content, which may increase operational costs.

Yes, cremating green wood requires careful monitoring to ensure complete combustion, and it may produce more smoke and emissions compared to dry wood, necessitating proper ventilation and filtration systems.