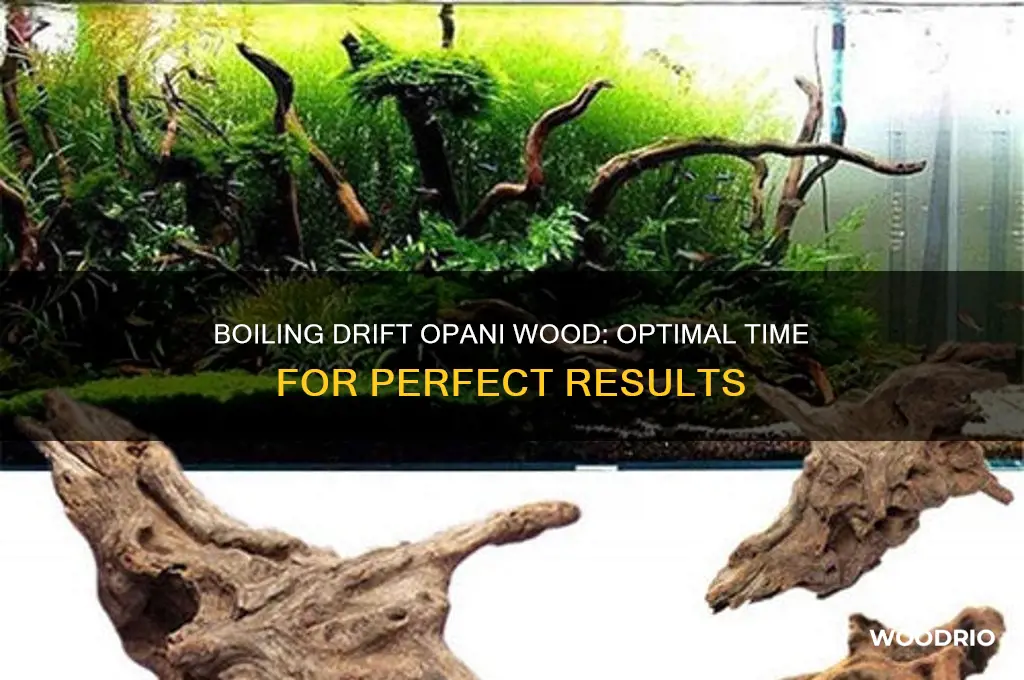

Boiling driftwood, such as opani wood, is a crucial step in preparing it for use in aquariums or terrariums, as it helps remove tannins, toxins, and potential pests. The duration required to boil opani wood depends on its size, density, and desired outcome, but generally, it should be boiled for at least 1 to 2 hours. Larger or thicker pieces may require multiple boiling sessions or longer durations, up to 4 hours, to ensure thorough cleaning and waterlogging. After boiling, the wood should be soaked in fresh water for several days to a week to further leach out tannins and stabilize it for its intended use. Always monitor the wood during boiling to prevent it from drying out or cracking, and consider weighing it down if it floats excessively.

Explore related products

What You'll Learn

Pre-Boil Preparation Steps

Drift opani wood, prized for its unique grain and durability, requires careful preparation before boiling to ensure optimal results. The pre-boil phase is critical for removing impurities, stabilizing the wood, and enhancing its natural beauty. Here’s a focused guide on the essential steps to take before submerging your drift opani wood in boiling water.

Step 1: Clean the Wood Thoroughly

Begin by scrubbing the wood with a stiff brush and mild detergent to remove dirt, salt, and debris accumulated during its time in the water. Rinse it under running water, ensuring no residue remains. For stubborn stains, a mixture of vinegar and water (1:1 ratio) can be applied, followed by a thorough rinse. This step prevents contaminants from affecting the wood’s appearance or structural integrity during boiling.

Step 2: Dry the Wood Gradually

Moisture trapped within the wood can cause cracking or warping when exposed to heat. Air-dry the wood in a well-ventilated area for 3–5 days, avoiding direct sunlight to prevent uneven drying. For faster results, use a dehumidifier or place the wood near a fan. Ensure the wood feels dry to the touch before proceeding, as residual moisture can lead to steam pockets during boiling.

Step 3: Inspect and Repair Cracks

Carefully examine the wood for cracks, splits, or weak spots. Minor cracks can be filled with wood epoxy or glue, while larger issues may require reinforcement with wooden dowels. Allow repairs to cure fully (typically 24 hours) before boiling. This step ensures the wood remains intact and structurally sound throughout the process.

Step 4: Pre-Soak for Even Absorption

Submerge the wood in a container of warm water for 2–4 hours before boiling. This pre-soak helps the wood absorb heat more evenly, reducing the risk of splitting. Add a tablespoon of salt per gallon of water to further stabilize the wood fibers. This preparatory soak mimics the boiling process on a gentler scale, preparing the wood for the higher temperatures to come.

By meticulously following these pre-boil preparation steps, you’ll set the stage for a successful boiling process that enhances the drift opani wood’s natural qualities. Each step addresses a specific challenge, ensuring the wood emerges from boiling ready for its intended use, whether as a decorative piece or functional item.

Woodpeckers' Long Beaks: Do They Really Eat Wood?

You may want to see also

Explore related products

Ideal Boiling Time Range

Boiling driftwood, particularly opani wood, requires precision to achieve the desired outcome without compromising its structural integrity. The ideal boiling time range typically falls between 1 to 3 hours, depending on the wood’s density, size, and intended use. Shorter durations (1 hour) are sufficient for smaller pieces or surface sterilization, while larger, denser pieces may require up to 3 hours to ensure thorough treatment. Always monitor the process to avoid over-boiling, which can lead to brittleness or discoloration.

From an analytical perspective, the boiling process serves two primary purposes: removing tannins and eliminating pests or pathogens. Tannins, responsible for staining water, are gradually extracted during boiling, with noticeable reduction occurring after the first hour. However, complete tannin removal may take closer to 3 hours, especially in older or more weathered wood. For pest control, a minimum of 2 hours is recommended to ensure any larvae or microorganisms are eradicated. Balancing these objectives within the 1- to 3-hour window is key to preserving the wood’s aesthetic and structural qualities.

Instructively, start by fully submerging the driftwood in a large pot of water, ensuring it’s covered by at least 2 inches of liquid. Bring the water to a rolling boil, then reduce the heat to a gentle simmer. For smaller pieces (under 6 inches), aim for 1 hour of boiling, checking periodically for tannin release. Larger pieces (over 12 inches) should be boiled for 2 to 3 hours, with occasional stirring to ensure even treatment. After boiling, allow the wood to cool in the water before removing it to prevent cracking.

Comparatively, boiling is often preferred over soaking or baking due to its efficiency in tannin removal and pest control. While soaking can take days to weeks, boiling achieves similar results in hours. Baking, though faster, risks drying out the wood unevenly, leading to warping. Boiling’s controlled heat distribution makes it the most reliable method, provided the ideal time range is observed. For example, a 10-inch piece of opani wood boiled for 2 hours will retain its natural texture while being free of tannins and pests, making it ideal for aquariums or decorative use.

Practically, always wear gloves when handling boiled wood, as it can remain hot for extended periods. Use a dedicated pot for boiling, as tannins may stain cookware. For aquarium use, rinse the wood thoroughly after boiling to remove any residual tannins. If the wood still releases color after the initial boil, repeat the process for an additional hour. By adhering to the 1- to 3-hour range and following these tips, you can effectively prepare driftwood for its intended purpose while maintaining its natural beauty.

Drying Time for Wood Siding on Aluminum: Essential Tips and Guidelines

You may want to see also

Explore related products

Checking Wood Readiness

Boiling driftwood, particularly opani wood, requires careful attention to ensure it’s fully prepared for its intended use. One critical step often overlooked is checking the wood’s readiness during the boiling process. This isn’t just about time—it’s about observing physical and structural changes that signal the wood is ready. For instance, opani wood typically begins to lighten in color and release tannins after 30–60 minutes of boiling, but these indicators alone aren’t definitive. Readiness depends on factors like wood density, size, and desired outcome (e.g., aquarium-safe or crafting purposes).

Analytical Approach:

The science behind checking wood readiness lies in understanding how boiling affects cellulose and lignin, the primary components of wood. As opani wood boils, cellulose softens, and lignin breaks down, making the wood more pliable and less prone to cracking. A practical test involves gently bending a small piece of the wood after 1–2 hours of boiling. If it flexes without snapping, it’s nearing readiness. However, over-boiling can lead to excessive brittleness, so monitoring structural integrity is key. For larger pieces, extend boiling time by 30-minute increments, checking after each interval.

Instructive Steps:

To check readiness, start by using tongs to remove a small section of the wood after the first hour of boiling. Allow it to cool briefly, then press your fingernail into the surface. If it leaves a slight indentation without splintering, the wood is softening appropriately. For aquarium use, test the water’s pH and clarity after boiling—tannins should be minimal, and the water should be slightly amber. If the water remains dark or pH drops below 6.0, continue boiling and replace the water every 30 minutes until stable.

Comparative Insight:

Unlike denser hardwoods, opani wood responds more quickly to boiling due to its porous structure. While oak or maple might require 4–6 hours to achieve similar results, opani often reaches readiness in 2–3 hours. However, this faster processing time demands vigilance. Over-boiled opani wood can become too soft, losing its shape, while under-boiled wood may retain harmful bacteria or toxins. Comparing opani to other driftwoods highlights the importance of tailoring the boiling duration and readiness checks to the specific wood type.

Descriptive Takeaway:

Imagine holding a piece of opani wood that’s been boiled to perfection: it’s lighter in hue, smooth to the touch, and emits a faint, earthy aroma. The surface is free of cracks, and when bent, it holds its shape without breaking. This is the goal of checking wood readiness—achieving a balance between softness and structural integrity. By observing color, texture, and flexibility, you ensure the wood is not just boiled, but transformed into a durable, safe material for its intended purpose.

Practical Tip:

Keep a timer and log observations during the boiling process. Note changes in water color, wood texture, and flexibility at 30-minute intervals. For aquarium enthusiasts, invest in a tannin remover or activated carbon to expedite water clarification post-boil. Crafters should air-dry the wood for 24–48 hours after boiling to stabilize its shape before sanding or carving. Patience and attention to detail are your best tools in mastering this process.

Navigating COVID Recovery: When Are You Truly Out of the Woods?

You may want to see also

Explore related products

Cooling and Drying Process

After boiling driftwood, the cooling and drying process is a delicate balance between preserving its natural beauty and ensuring structural integrity. Rapid cooling can cause cracks or warping, while improper drying may lead to mold or decay. To avoid these pitfalls, start by allowing the wood to cool gradually in the boiling water. This process, known as annealing, helps relieve internal stresses built up during boiling. Once the water reaches room temperature, remove the wood and gently pat it dry with a clean cloth to remove excess moisture.

The drying phase is where patience becomes paramount. Place the driftwood in a well-ventilated area, away from direct sunlight or heat sources, which can cause uneven drying. A humidity level below 50% is ideal to prevent mold growth. For larger pieces, consider using a fan to circulate air, but avoid high-speed settings that could stress the wood. Smaller pieces may dry within a week, while larger logs can take several weeks. Monitor the wood regularly, checking for signs of cracking or warping, and adjust the drying environment as needed.

A comparative analysis of drying methods reveals that air-drying is the most natural and cost-effective approach, though it requires time. Kiln-drying, while faster, is impractical for most hobbyists due to the specialized equipment required. Another method, oven-drying at low temperatures (140°F or 60°C), can expedite the process but carries a higher risk of damage if not closely monitored. For driftwood enthusiasts, air-drying remains the safest and most accessible option, preserving the wood’s unique textures and colors.

To enhance the drying process, consider applying a thin coat of wood preservative or natural oil once the wood is partially dried. This step not only protects against moisture but also enriches the wood’s appearance. However, avoid using heavy sealants until the wood is completely dry, as they can trap residual moisture. Practical tips include rotating the wood periodically to ensure even drying and using a moisture meter to confirm the wood’s internal moisture content is below 15% before use.

In conclusion, the cooling and drying process is as critical as boiling itself in preparing driftwood for crafting or display. By prioritizing gradual cooling, controlled drying conditions, and regular monitoring, you can preserve the wood’s natural beauty while ensuring its longevity. Whether you’re a seasoned artisan or a beginner, mastering this phase will elevate the quality of your driftwood projects.

When Will Wood Prices Drop? A Forecast for Buyers

You may want to see also

Explore related products

Common Boiling Mistakes

Boiling driftwood, particularly opani wood, is a delicate process that requires precision and patience. One common mistake is overboiling, which can lead to the wood becoming brittle or losing its natural oils. While there’s no one-size-fits-all boiling time, most sources suggest 1–2 hours for opani wood, depending on its density and size. Exceeding this timeframe, even by 30 minutes, can strip the wood of its unique texture and color, rendering it unsuitable for aquariums or decorative purposes. Always monitor the wood closely after the first hour, testing its flexibility to avoid over-treatment.

Another frequent error is neglecting to pre-soak the wood before boiling. Opani wood, like many driftwoods, contains tannins that can discolor water and leach into the environment. Soaking the wood for 24–48 hours in a bucket of water, changing it daily, helps remove these tannins and reduces boiling time. Skipping this step not only prolongs the boiling process but also increases the risk of water discoloration, which can be problematic for aquarium setups. Think of pre-soaking as the essential prep work that sets the stage for successful boiling.

A less obvious but equally critical mistake is using the wrong pot or container. Boiling opani wood requires a large, non-reactive vessel, such as stainless steel or ceramic. Aluminum or copper pots can react with the tannins, altering the wood’s appearance and potentially releasing harmful substances. Additionally, the pot should be at least twice the size of the wood to allow for even heat distribution and prevent overcrowding. Using an undersized or reactive container can lead to uneven boiling, leaving parts of the wood untreated or damaged.

Finally, ignoring water quality is a mistake that often goes unnoticed. Tap water contains minerals and chemicals like chlorine that can affect the boiling process. For best results, use distilled or dechlorinated water, especially if the wood is intended for aquarium use. Chlorine, in particular, can react with tannins, prolonging boiling time and leaving residue on the wood. Investing in a simple water conditioner or opting for distilled water ensures a cleaner, more efficient boil, preserving the wood’s natural beauty and safety for aquatic life.

By avoiding these common pitfalls—overboiling, skipping pre-soaking, using improper containers, and disregarding water quality—you can ensure that your opani wood is safely and effectively prepared for its intended use. Each step, though small, plays a crucial role in the overall outcome, transforming raw driftwood into a polished, functional piece.

Elmer's Wood Glue Shelf Life: Durability and Storage Tips Revealed

You may want to see also

Frequently asked questions

Boil driftwood for at least 1-2 hours, but for heavily tannin-rich wood like opani, extend the boiling time to 3-4 hours. Repeat the process daily for 3-7 days, changing the water each time, until the water remains clear.

Yes, boiling is primarily necessary for aquarium use to remove tannins and potential toxins. If using driftwood for decorative purposes, you can skip boiling, but consider soaking it in water for a few days to remove dirt and debris.

The driftwood is ready when the water remains clear after boiling and soaking for several days. Additionally, test the water for tannins using a tannin test kit or by observing if it stains a white cloth. If no tannins are detected, the wood is safe to use.