Drying apple wood is a crucial step for anyone looking to use it for smoking, cooking, or crafting, as it ensures the wood burns efficiently and imparts its signature sweet, fruity flavor. The time required to dry apple wood depends on several factors, including the wood’s moisture content, the thickness of the pieces, and the drying conditions. Typically, freshly cut apple wood can take anywhere from 6 months to 2 years to fully season, with smaller pieces drying faster than larger logs. Proper airflow, protection from rain, and a dry, shaded environment are essential to prevent mold and ensure even drying. For those seeking quicker results, kiln-drying can reduce the time to just a few weeks, though this method requires specialized equipment. Understanding the drying process is key to maximizing the wood’s quality and usability.

| Characteristics | Values |

|---|---|

| Drying Time (Air Drying) | 6 months to 2 years, depending on thickness and climate conditions |

| Moisture Content Goal | 20% or less for optimal burning |

| Splitting Recommendation | Split logs into 4-6 inch pieces for faster drying |

| Stacking Method | Stack wood in a dry, well-ventilated area, off the ground, and covered |

| Kiln Drying Time | 2-4 weeks, significantly faster than air drying |

| Ideal Drying Conditions | Low humidity (below 60%), good airflow, and protection from rain/snow |

| Checking Dryness | Wood should be lighter in weight, ends may crack, and it makes a hollow sound when tapped |

| Seasoning Indicator | Bark may peel or come off easily when properly dried |

| Storage After Drying | Store in a dry, covered area to prevent reabsorption of moisture |

| Best Use After Drying | Ideal for smoking meats, firewood, or woodworking projects |

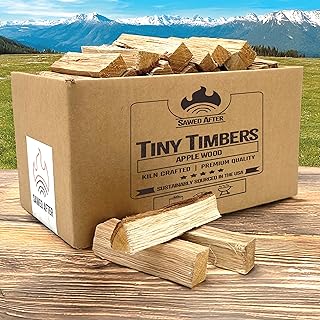

Explore related products

What You'll Learn

- Optimal Drying Conditions: Sunlight, airflow, and low humidity speed up apple wood drying efficiently

- Seasoning Timeframe: Typically takes 6–12 months for apple wood to fully dry and cure

- Moisture Content Check: Use a moisture meter; aim for 20% or less for proper dryness

- Stacking Techniques: Split and stack wood loosely to enhance air circulation during drying

- Indoor vs. Outdoor Drying: Outdoor drying is faster, but indoor storage prevents mold and pests

Optimal Drying Conditions: Sunlight, airflow, and low humidity speed up apple wood drying efficiently

Drying apple wood is a delicate balance of patience and precision, but optimal conditions can significantly reduce the waiting time. Sunlight, airflow, and low humidity are the trifecta of factors that accelerate this process, transforming raw wood into a usable material for smoking, crafting, or firewood. Understanding how these elements interact with the wood’s moisture content is key to achieving efficient drying without compromising quality.

Analytical Insight: Sunlight acts as a natural catalyst in the drying process, providing both heat and UV radiation that break down surface moisture. However, direct sunlight can cause uneven drying, leading to cracks or warping. To mitigate this, position the wood in a way that maximizes exposure during the cooler parts of the day, such as morning or late afternoon. This approach ensures the wood benefits from solar energy without the risk of overheating. Pairing sunlight with consistent airflow amplifies its effectiveness, as moving air carries moisture away from the wood’s surface, preventing saturation.

Instructive Steps: To optimize drying, stack apple wood in a single layer on a raised platform or rack, ensuring each piece is spaced at least 1–2 inches apart. This arrangement promotes airflow around all sides of the wood. Place the setup in a well-ventilated area with partial sunlight, such as under a shade cloth or near a wall that blocks harsh midday rays. For best results, aim for a humidity level below 50%, which can be monitored using a hygrometer. If natural conditions are unfavorable, consider using fans to enhance airflow or dehumidifiers to reduce moisture in the environment.

Comparative Perspective: Compared to air-drying in a damp, shaded area, which can take 6–12 months, combining sunlight, airflow, and low humidity reduces drying time to 3–6 months. For instance, apple wood dried in a sunny, breezy location with humidity control reaches a moisture content of 20% (ideal for smoking) in as little as 4 months, whereas wood left in a humid, stagnant environment may never drop below 30%. This comparison highlights the efficiency gained by manipulating environmental factors.

Practical Tips: Rotate the wood periodically to ensure even drying and inspect for mold or insect infestations, which thrive in damp conditions. If rain is frequent, cover the wood with a waterproof tarp, ensuring it’s loose enough to allow airflow. For those in humid climates, consider kiln-drying as an alternative, though it requires specialized equipment. Finally, test the wood’s moisture level using a moisture meter; readings between 15–20% indicate readiness for use.

Persuasive Takeaway: Investing time in creating optimal drying conditions pays dividends in both speed and quality. While it may require initial effort to set up the right environment, the reduced drying time and superior end product make it a worthwhile endeavor. Whether for smoking meats or crafting furniture, properly dried apple wood enhances the final outcome, proving that nature’s tools—sunlight, airflow, and low humidity—are the most effective when harnessed thoughtfully.

Tom Ford Oud Wood Longevity: How Long Does It Last?

You may want to see also

Explore related products

Seasoning Timeframe: Typically takes 6–12 months for apple wood to fully dry and cure

Apple wood, prized for its sweet aroma and steady burn, demands patience. The seasoning process, a critical phase in transforming freshly cut logs into prime firewood, typically spans 6 to 12 months. This timeframe isn’t arbitrary; it’s rooted in the wood’s density and moisture content. Apple wood, being moderately dense, retains water more stubbornly than softer woods like pine. Rushing this process risks incomplete drying, leading to inefficient burning, excessive smoke, and creosote buildup in chimneys.

To optimize seasoning, start by splitting logs into 4- to 6-inch lengths, exposing more surface area to air. Stack the wood in a single row, off the ground, and cover the top with a tarp while leaving the sides open for airflow. Placement matters: choose a sunny, well-ventilated spot to accelerate evaporation. Monitor progress by checking the wood’s weight or using a moisture meter; seasoned apple wood should read below 20% moisture content.

Comparatively, hardwoods like oak or hickory may take up to 2 years to season fully, while softer woods like ash can dry in 6 months. Apple wood falls in the middle, making it a manageable choice for those willing to wait. However, regional climate plays a role—humid areas may extend the timeline, while arid regions can shorten it.

For those eager to use apple wood sooner, kiln-drying offers a shortcut, reducing the process to weeks. However, this method sacrifices the natural aging that enhances flavor and burn quality. Traditional air-drying, though slower, preserves the wood’s unique characteristics, making it ideal for smoking meats or heating homes.

In conclusion, the 6- to 12-month seasoning timeframe for apple wood is a balance of science and tradition. By respecting this timeline and following best practices, you ensure a superior product that rewards your patience with clean, fragrant, and efficient combustion.

Ipe Wood Durability: Lifespan, Maintenance, and Longevity Explained

You may want to see also

Explore related products

Moisture Content Check: Use a moisture meter; aim for 20% or less for proper dryness

Drying apple wood is a delicate balance between time and moisture content. While air-drying times can vary widely—from several months to over a year—relying solely on time is unreliable. Wood dries at different rates based on thickness, humidity, and temperature. This is where a moisture meter becomes indispensable. By measuring the wood’s internal moisture levels, you eliminate guesswork and ensure the wood is truly ready for use.

A moisture meter is a straightforward tool that provides precise readings, typically in percentage points. For apple wood, the target moisture content is 20% or less. This threshold is critical because wood above 20% moisture is prone to warping, cracking, and mold growth, especially when used for projects like smoking meats or crafting furniture. To use the meter, insert the probes into the wood at multiple points, avoiding the end grain, which dries faster and can give misleading readings.

Not all moisture meters are created equal. Pin-type meters offer accuracy but leave small holes, while pinless meters are non-invasive but may be less precise on thicker pieces. For apple wood, a pin-type meter is often preferred for its reliability. Aim to test the wood in the morning and evening to account for daily moisture fluctuations. If readings consistently show 20% or lower, the wood is dry enough for use.

Comparing moisture content to drying time highlights why the meter is essential. For instance, a 2-inch thick apple wood log might take 6–12 months to air-dry in a temperate climate, but without a moisture meter, you risk using wood that appears dry externally but remains damp internally. This internal moisture can ruin projects, making the meter a small investment with significant returns.

In practice, once the wood reaches 20% moisture content, store it in a dry, well-ventilated area to prevent reabsorption of moisture. For smoking, ensure the wood is split into smaller pieces to expedite drying and allow for even moisture loss. By prioritizing moisture content over time, you guarantee the apple wood’s stability and quality, whether for culinary or crafting purposes.

Choosing the Right Screw Length for Wood Studs: A Guide

You may want to see also

Explore related products

Stacking Techniques: Split and stack wood loosely to enhance air circulation during drying

Proper stacking is a critical yet often overlooked step in drying apple wood effectively. The goal is to maximize air circulation, which accelerates moisture evaporation and prevents mold or rot. Start by splitting the wood into manageable pieces, ideally 4 to 6 inches in diameter, to expose more surface area to the air. Larger pieces can be used but will take significantly longer to dry—up to 24 months compared to 6 to 12 months for smaller splits. Splitting also helps release trapped moisture, a key factor in reducing drying time.

Once split, stack the wood loosely in a crisscross pattern, ensuring gaps between pieces. Avoid tight piles, as these restrict airflow and create pockets of trapped moisture. A well-stacked pile should resemble a dry stone wall, with enough space for air to flow freely through the stack. Elevate the pile off the ground using pallets or logs to prevent ground moisture from seeping in. Position the stack in a sunny, well-ventilated area, ideally facing south to maximize sun exposure, which aids in drying.

Comparing loose stacking to tight stacking reveals stark differences in drying efficiency. A tightly stacked 4-foot cord of apple wood may retain moisture for 18 months or more, while a loosely stacked equivalent can dry in half that time. The key lies in surface exposure and airflow: loose stacks allow air to circulate around each piece, carrying away moisture vapor. In contrast, tight stacks create a humid microclimate that slows evaporation and fosters fungal growth.

For optimal results, monitor the stack periodically, especially after rain or high humidity. If mold appears, rearrange the stack to improve airflow and remove affected pieces. Covering the top of the stack with a tarp can protect it from rain while leaving the sides open for ventilation. Patience is essential; rushing the process by over-stacking or using heat can compromise the wood’s integrity. With proper technique, your apple wood will be ready for smoking or burning in the recommended timeframe, ensuring a high-quality end product.

Termite Lifespan Secrets: How Long Can They Survive Without Wood?

You may want to see also

Explore related products

Indoor vs. Outdoor Drying: Outdoor drying is faster, but indoor storage prevents mold and pests

Drying apple wood outdoors accelerates the process significantly, thanks to natural elements like sunlight and wind. Ideal conditions—temperatures above 70°F (21°C) and low humidity—can reduce drying time from months to weeks. For instance, a 4-inch diameter log might dry in 6–8 weeks outdoors, compared to 6–12 months indoors. However, this speed comes with risks. Outdoor drying exposes wood to unpredictable weather, which can lead to cracking or uneven moisture loss if not monitored.

Indoor drying, while slower, offers control and protection. By storing wood in a well-ventilated, dry space with consistent temperatures (50–70°F or 10–21°C), you minimize the risk of mold and pests. For best results, stack wood on pallets or racks to allow airflow, and maintain humidity below 50%. This method is ideal for smaller pieces or when precision is critical, such as for woodworking projects. However, patience is required—expect drying times of 6–18 months, depending on thickness.

The choice between indoor and outdoor drying hinges on your priorities. If time is critical and you can manage environmental risks, outdoor drying is efficient. Conversely, indoor storage ensures quality and longevity, particularly for wood intended for smoking or crafting. For example, apple wood used for smoking meats benefits from indoor drying to preserve its sweet, fruity aroma without contamination.

Practical tips: For outdoor drying, cover wood with a breathable tarp to shield it from rain while allowing airflow. Indoors, use a dehumidifier to maintain optimal conditions. Always split logs into manageable sizes (2–4 inches thick) before drying, as this exposes more surface area and speeds up the process. Whether you choose speed or safety, understanding these methods ensures your apple wood dries effectively for its intended use.

Durability of Wooden Posts Submerged Underwater: Lifespan and Factors

You may want to see also

Frequently asked questions

Apple wood typically takes 6 to 12 months to air dry properly, depending on humidity, temperature, and the thickness of the wood pieces.

Yes, you can speed up drying by splitting the wood into smaller pieces, storing it in a dry, well-ventilated area, and using a kiln, though air drying is preferred for smoking.

Fully dried apple wood will have a moisture content of 20% or less, feel lighter, and make a sharp, clear sound when tapped together.

Using wet or partially dried apple wood can result in excessive smoke and a bitter taste. Always ensure it’s fully dried for the best flavor.