Drying wood in a kiln is a highly efficient method used to reduce moisture content to optimal levels for woodworking, construction, or other applications. The time required to dry wood in a kiln varies significantly depending on several factors, including the wood species, initial moisture content, thickness of the wood, kiln type, and desired final moisture level. Softwoods typically dry faster than hardwoods, and thinner pieces dry more quickly than thicker ones. On average, kiln drying can take anywhere from a few days to several weeks, with some hardwoods requiring up to a month or more. Proper kiln operation, including controlled temperature, humidity, and airflow, is crucial to ensure even drying and prevent defects like warping or cracking. Understanding these variables is essential for achieving the desired results while maximizing efficiency and minimizing energy consumption.

| Characteristics | Values |

|---|---|

| Kiln Drying Time | 2-14 days (varies based on wood species, thickness, and moisture content) |

| Temperature Range | 120°F to 200°F (49°C to 93°C) |

| Humidity Control | Gradually reduced from 90% to 20% relative humidity |

| Wood Thickness | Thicker wood requires longer drying times (e.g., 4/4 lumber: 3-7 days, 8/4 lumber: 7-14 days) |

| Moisture Content Reduction | From 20-30% (green wood) to 6-8% (air-dried) or 6-12% (kiln-dried) |

| Wood Species Impact | Hardwoods (e.g., oak, maple) dry slower than softwoods (e.g., pine, fir) |

| Energy Consumption | Varies; modern kilns use 1,000-2,000 BTU per pound of water removed |

| Dehumidification Method | Uses heated air circulation and dehumidifiers to remove moisture |

| Stress Relief | Reduces warping, cracking, and twisting compared to air drying |

| Cost Efficiency | Higher initial cost but faster and more consistent than air drying |

| Environmental Impact | Controlled process reduces waste and energy use compared to traditional methods |

Explore related products

What You'll Learn

- Kiln Type Impact: Different kilns (dehumidification, solar, conventional) affect drying time significantly

- Wood Species Variation: Hardwoods dry slower than softwoods due to density differences

- Moisture Content Levels: Higher initial moisture content extends drying duration in kilns

- Temperature & Humidity Control: Optimal settings speed up drying while preventing cracks

- Thickness & Size Factors: Thicker or larger wood pieces require more time to dry

Kiln Type Impact: Different kilns (dehumidification, solar, conventional) affect drying time significantly

The type of kiln used for drying wood is a critical factor in determining the overall drying time, with each method offering distinct advantages and limitations. Dehumidification kilns, for instance, operate by removing moisture from the air within the kiln, creating an environment that encourages wood to release its internal moisture. This process is particularly effective for delicate or high-value wood species, as it allows for precise control over temperature and humidity levels. A typical dehumidification kiln can reduce the moisture content of wood from 20% to 8% in approximately 4-6 weeks, depending on the thickness and density of the wood. This method is ideal for small-scale operations or hobbyists seeking consistent, high-quality results.

In contrast, solar kilns harness the power of the sun to dry wood, making them an eco-friendly and cost-effective option. These kilns consist of a transparent cover, often made of polycarbonate or glass, which traps solar energy and heats the interior space. While solar kilns are highly efficient in warm, sunny climates, their drying times can be significantly longer than other methods, ranging from 8-12 weeks or more. The variability in weather conditions also introduces an element of unpredictability, making it challenging to maintain consistent drying schedules. However, for those with access to ample sunlight and patience, solar kilns offer a sustainable solution with minimal operating costs.

Conventional kilns, which rely on steam or electric heating elements, are the most widely used method for industrial-scale wood drying. These kilns can achieve high temperatures and rapid air circulation, significantly reducing drying times to as little as 2-4 weeks for standard lumber thicknesses. However, this speed comes at the expense of energy consumption and potential for overheating, which can lead to cracks, warping, or discoloration in the wood. To mitigate these risks, operators must carefully monitor temperature and humidity levels, often using automated control systems to maintain optimal conditions.

A comparative analysis of these kiln types reveals that the choice of method depends largely on the specific needs and constraints of the user. For instance, a small furniture maker prioritizing wood quality might opt for a dehumidification kiln, despite its longer drying time, to ensure minimal defects. Conversely, a large sawmill focused on high-volume production would likely favor a conventional kiln for its speed and efficiency, accepting the increased energy costs as a necessary trade-off. Solar kilns, while slower, present an attractive option for environmentally conscious operations or those in regions with abundant sunlight.

To maximize efficiency and minimize defects when using any kiln type, it’s essential to follow best practices such as proper stacking of lumber to allow for adequate air circulation, regular monitoring of moisture content using a reliable meter, and gradual temperature increases to avoid shocking the wood. Additionally, understanding the specific requirements of the wood species being dried—such as the optimal moisture content for stability and workability—can further refine the drying process. By carefully selecting the kiln type and adhering to these guidelines, woodworkers and manufacturers can achieve the desired results while optimizing time and resources.

Pressure Treated Wood Lifespan in Soil: Durability and Longevity Explained

You may want to see also

Explore related products

Wood Species Variation: Hardwoods dry slower than softwoods due to density differences

The drying time of wood in a kiln is not a one-size-fits-all process. A critical factor dictating this duration is the inherent density of the wood species. Hardwoods, with their tightly packed cellular structure, present a more formidable challenge to moisture removal compared to their softer counterparts. This density disparity translates to a slower drying process for hardwoods, demanding careful consideration in kiln scheduling.

Imagine attempting to wring water from a thick, plush towel versus a thin, lightweight one. The denser towel, akin to hardwood, will retain moisture longer, requiring more time and effort to dry completely.

This density-driven drying differential necessitates species-specific kiln schedules. For instance, a kiln operator drying oak, a dense hardwood, would employ a longer drying cycle with lower temperatures compared to drying pine, a softer wood. Pushing the drying process too quickly with hardwoods can lead to detrimental consequences like warping, cracking, or even internal stresses that compromise the wood's structural integrity.

Understanding these species-specific drying characteristics is paramount for achieving optimal results. Kiln operators must meticulously monitor moisture content throughout the drying process, adjusting temperature and humidity levels accordingly to ensure uniform drying without sacrificing wood quality.

While kiln drying offers a controlled environment for efficient moisture removal, the inherent density of hardwoods dictates a more patient approach. Attempting to expedite the process can be counterproductive, leading to costly defects. By respecting the natural characteristics of different wood species and tailoring kiln schedules accordingly, woodworkers can ensure the production of high-quality, dimensionally stable lumber.

Seasoning Miller Wood: Understanding the Time It Takes to Dry Properly

You may want to see also

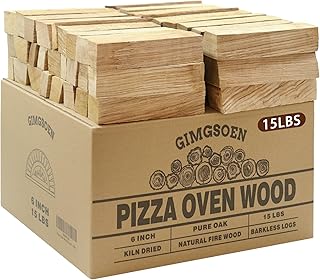

Explore related products

$55

Moisture Content Levels: Higher initial moisture content extends drying duration in kilns

The initial moisture content of wood is a critical factor in determining how long it will take to dry in a kiln. Wood freshly cut from a tree, known as green wood, can have a moisture content of 50% or higher. For context, wood is typically considered dry and ready for use when its moisture content drops to around 6-12%, depending on the intended application. This significant reduction in moisture requires time, energy, and precise control within the kiln environment.

Consider the drying process as a journey from saturation to equilibrium. Higher initial moisture content means there’s more water to remove, which directly translates to longer drying times. For instance, drying wood from 50% moisture content to 10% can take anywhere from 2 to 6 weeks in a kiln, depending on the species, thickness, and kiln efficiency. In contrast, wood with an initial moisture content of 30% might dry to the same level in half the time. This relationship is not linear; the rate of moisture loss slows as the wood approaches its equilibrium moisture content, making the final stages of drying particularly time-consuming.

To optimize drying times, kiln operators must balance temperature, humidity, and airflow. Higher temperatures accelerate evaporation but risk cracking or warping the wood if applied too aggressively. A common strategy is to start with lower temperatures (around 120°F) to gently remove surface moisture, then gradually increase the heat (up to 180°F) as the wood dries. Humidity control is equally important; maintaining a relative humidity of 20-30% in the kiln encourages moisture to escape without causing stress to the wood fibers.

Practical tips for managing moisture content include pre-drying wood in a shed or under cover before kiln drying, which can reduce initial moisture levels by 10-15%. Additionally, monitoring moisture content with a pin-type or pinless moisture meter allows operators to adjust kiln settings in real time, ensuring the wood dries evenly without over-drying. For hardwoods like oak or maple, which are denser and hold moisture more stubbornly, extending the drying cycle by 20-30% is often necessary to achieve the desired moisture content.

In summary, higher initial moisture content in wood directly correlates with longer kiln-drying times. By understanding this relationship and employing strategic kiln management techniques, operators can minimize drying duration while preserving wood quality. Whether you’re working with softwoods like pine or dense hardwoods like walnut, tailoring the drying process to the wood’s starting moisture level is key to efficiency and success.

The Lifespan of Wooden Ships: Durability, Maintenance, and Preservation Tips

You may want to see also

Explore related products

$52.99 $69.99

Temperature & Humidity Control: Optimal settings speed up drying while preventing cracks

Drying wood in a kiln is a delicate balance of science and art, where temperature and humidity control are the maestros orchestrating the process. The goal is clear: accelerate moisture removal without inviting cracks, warping, or other defects. Optimal settings hinge on understanding the wood’s species, thickness, and initial moisture content, but general principles apply. Temperatures typically range from 120°F to 160°F (49°C to 71°C), with humidity levels adjusted to match the drying phase. For instance, during the initial drying stage, higher humidity (around 80-90%) prevents surface checking, while later stages require lower humidity (below 40%) to expel residual moisture efficiently.

Consider the kiln schedule as a recipe, where each step builds on the last. Start with a low-temperature, high-humidity phase to equalize moisture content throughout the wood, ensuring the exterior doesn’t dry faster than the interior. Gradually increase the temperature while reducing humidity to drive moisture out without stressing the wood fibers. For hardwoods like oak or maple, this process might take 2-4 weeks, while softer woods like pine dry faster, often within 1-2 weeks. Monitoring with moisture meters ensures precision, as even small deviations can lead to cracks or case hardening.

The persuasive argument here is clear: investing time in precise temperature and humidity control pays dividends in wood quality. A rushed drying process, with temperatures exceeding 180°F (82°C) or abrupt humidity drops, risks irreversible damage. Conversely, overly conservative settings prolong drying time unnecessarily, tying up resources. The sweet spot lies in incremental adjustments, guided by data and experience. For example, a 2-inch thick hardwood board might require a 10°F (5.5°C) temperature increase every 24 hours, paired with a 10% humidity reduction, to maintain equilibrium.

Comparatively, air-drying lacks the control of a kiln, leaving wood vulnerable to environmental fluctuations. Kiln drying, when executed with optimal settings, not only speeds up the process but also enhances consistency. Imagine two batches of lumber: one air-dried over six months, the other kiln-dried in three weeks. The kiln-dried batch will exhibit fewer defects, uniform moisture content, and readiness for immediate use. This efficiency is particularly valuable for commercial operations, where time and quality directly impact profitability.

In practice, achieving optimal settings requires vigilance and adaptability. Use dehumidifiers and heaters to maintain precise conditions, and regularly inspect the wood for signs of stress. For thicker pieces, consider a vacuum kiln, which allows for higher temperatures without risk of cracking by reducing atmospheric pressure. Pairing technology with traditional techniques—like stacking wood with spacers to promote airflow—maximizes efficiency. Remember, the kiln is not just a tool but a partner in crafting wood that’s stable, durable, and ready for its next chapter.

Optimal Corner Brace Length for Sturdy Wooden Frame Construction Guide

You may want to see also

Explore related products

Thickness & Size Factors: Thicker or larger wood pieces require more time to dry

The drying time of wood in a kiln is not a one-size-fits-all process. A critical factor that significantly influences this duration is the thickness and size of the wood pieces. As a general rule, thicker or larger wood requires more time to dry compared to thinner or smaller pieces. This is because moisture must travel a greater distance from the core to the surface of the wood, where it can evaporate. For instance, a 4/4 (1-inch thick) board might dry in 2-4 weeks, while an 8/4 (2-inch thick) board could take 6-8 weeks or longer under the same kiln conditions.

To illustrate, consider the moisture content gradient within a thick piece of wood. During the initial stages of drying, moisture from the outer layers evaporates quickly, but as the process continues, the remaining moisture is deeper within the wood. This creates a diffusion process where water molecules migrate from the saturated core to the drier surface. The rate of this diffusion is slower in thicker wood, leading to longer drying times. Kiln operators often use scheduled drying programs, adjusting temperature and humidity to prevent surface checking or internal stresses, which are more likely in thicker pieces.

From a practical standpoint, woodworkers and kiln operators must account for thickness when planning drying schedules. For example, if drying a batch of mixed-thickness lumber, it’s advisable to separate thicker pieces and allocate additional time for them. Ignoring this factor can result in uneven drying, where thinner pieces become overly dry or even damaged while thicker ones remain wet. A useful tip is to use moisture meters to monitor progress, ensuring that thicker wood reaches the desired moisture content (typically 6-8% for indoor use) without compromising quality.

Comparatively, air-drying thick wood can take months or even years, making kiln-drying a more efficient option despite the extended time required. However, the controlled environment of a kiln allows for precise management of temperature and humidity, reducing the risk of defects. For larger projects, such as drying beams or slabs, pre-planning is essential. Operators might start with lower temperatures to gently remove surface moisture, gradually increasing heat to address deeper moisture without causing cracks.

In conclusion, understanding the relationship between wood thickness and drying time is crucial for achieving optimal results in a kiln. By tailoring drying schedules to the size and thickness of the wood, operators can minimize defects, improve efficiency, and produce high-quality lumber. Whether you’re a professional or hobbyist, recognizing this factor ensures that your wood is not only dry but also structurally sound and ready for use.

Understanding Wood Primer Cure Time: A Comprehensive Guide for DIYers

You may want to see also

Frequently asked questions

The drying time in a kiln varies depending on the wood species, thickness, and moisture content, but it generally ranges from 2 to 14 days.

Yes, drying time can be reduced by increasing kiln temperature, improving airflow, and using dehumidification systems, but care must be taken to avoid cracking or warping the wood.

Factors include the initial moisture content of the wood, its density and thickness, the kiln's temperature and humidity settings, and the efficiency of airflow within the kiln.