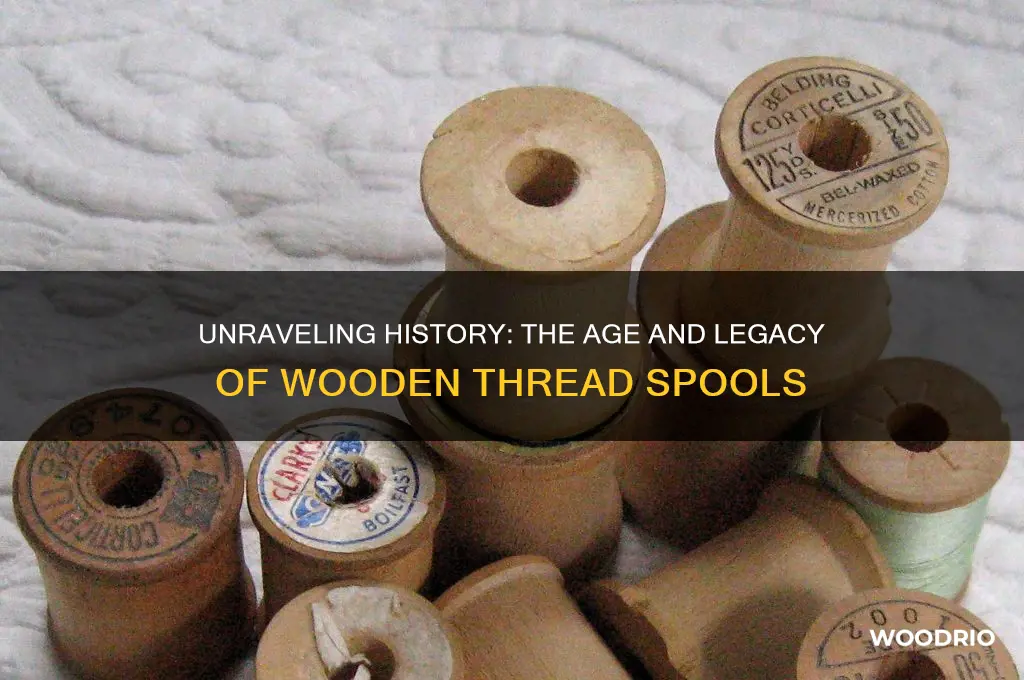

Wooden thread spools, often overlooked yet historically significant, have been integral to the textile industry for centuries. These small, cylindrical objects, typically crafted from hardwoods like maple or birch, were widely used to organize and dispense threads, especially during the Industrial Revolution. While their exact origins are somewhat obscure, evidence suggests that wooden spools date back to the 18th century, with their design evolving alongside advancements in textile manufacturing. Today, antique wooden thread spools are cherished by collectors and historians alike, offering a tangible link to the past and a glimpse into the craftsmanship and ingenuity of earlier eras. Determining their age often involves examining factors such as material, construction techniques, and manufacturer markings, making them a fascinating subject for those interested in industrial history and vintage artifacts.

| Characteristics | Values |

|---|---|

| Material | Wood (typically hardwoods like maple, birch, or beech) |

| Age Range | 19th century - mid-20th century (most common) |

| Manufacturing Period | Peak production: late 1800s to 1950s |

| Purpose | Holding and dispensing thread for sewing and textile industries |

| Size | Varies; common diameters: 1-3 inches (2.5-7.6 cm); height: 1-2 inches (2.5-5 cm) |

| Shape | Cylindrical with a central hole for thread |

| Markings | Often stamped with manufacturer names, logos, or thread brand information |

| Condition | Vintage spools may show wear, cracks, or paint chipping |

| Collectibility | Highly collectible, especially those with unique markings or from well-known brands |

| Value | Ranges from $1 to $50+ depending on rarity, condition, and historical significance |

| Historical Significance | Reflects the evolution of the textile industry and home sewing practices |

| Modern Usage | Repurposed for crafts, decor, or as collectibles |

| Preservation | Best preserved in dry, cool environments to prevent wood deterioration |

Explore related products

What You'll Learn

- Historical Origins: Early wooden spool manufacturing dates and techniques

- Antique Identification: Key features to determine age of old spools

- Material Aging: How wood deteriorates over time on spools

- Collectors' Insights: Expert tips for dating wooden thread spools

- Preservation Methods: Best practices to maintain spool longevity

Historical Origins: Early wooden spool manufacturing dates and techniques

The earliest wooden thread spools emerged in the late 18th century, coinciding with the rise of mechanized textile production. Before this, thread was wound onto rudimentary wooden sticks or directly onto cards, a labor-intensive process that limited efficiency. The invention of the spinning jenny and later the spinning frame created a demand for standardized, reusable thread holders. Early spools were handcrafted, often from hardwoods like maple or beech, chosen for their durability and ease of turning. These spools featured a simple cylindrical shape with a central hole, designed to fit onto the spindles of early spinning machines.

Hand-turning was the primary technique for manufacturing wooden spools until the mid-19th century. Skilled craftsmen used lathes to shape each spool individually, a time-consuming process that restricted production volume. The advent of the industrial revolution brought mechanized spool-making machines, revolutionizing the industry. These machines could produce spools with greater precision and speed, meeting the growing demand from textile mills. By the 1850s, wooden spools were being mass-produced, with standardized sizes and designs that ensured compatibility across different machines.

One of the most significant innovations in early spool manufacturing was the introduction of the "flanged" design. Flanged spools featured raised edges on both ends, preventing the thread from slipping off during high-speed winding. This design became the industry standard by the late 19th century, improving efficiency and reducing waste in textile production. The flanged spool’s success highlights the interplay between technological advancements in both spool manufacturing and textile machinery.

Despite the shift toward plastic spools in the mid-20th century, wooden spools remain historically significant. Their evolution from handcrafted items to mass-produced commodities reflects broader trends in industrialization and standardization. Collectors and historians value early wooden spools not only for their functional design but also as artifacts of a bygone era. For those interested in preserving or replicating early spool designs, studying the transition from hand-turning to mechanized production offers valuable insights into the craftsmanship and innovation of the period.

Jasmine Blooming Secrets: Does It Thrive on Old Wood?

You may want to see also

Explore related products

Antique Identification: Key features to determine age of old spools

Wooden thread spools, often overlooked, hold a wealth of history in their grooves and patina. To determine their age, start by examining the material and construction. Early spools, dating back to the 18th and 19th centuries, were typically hand-turned from hardwoods like maple or beech. These spools often exhibit tool marks from the lathe and may have irregular shapes due to the handcrafted nature of their creation. In contrast, mass-produced spools from the late 19th and early 20th centuries are more uniform, made from softer woods like pine, and often feature smoother finishes. Identifying the wood type and construction method provides a foundational clue to the spool’s era.

Next, inspect the markings and labels on the spool. Pre-1850 spools rarely bear any manufacturer’s marks, as branding was not yet a common practice. By the late 19th century, companies began stamping or printing their names, logos, and sometimes patent dates on spools. For instance, a spool marked with “Clark’s O.N.T.” likely dates to the late 1800s or early 1900s, as this was a prominent thread brand during that period. Additionally, spools with metric measurements (e.g., meters) instead of yards typically postdate the 1970s, reflecting the shift to the metric system in many countries.

The design and functionality of the spool also offer age-related insights. Early spools were often simple cylinders with a single hole, designed for winding thread by hand. By the mid-19th century, spools with notched edges or flanges appeared, facilitating machine sewing. The introduction of cross-wound spools, where thread is wrapped diagonally rather than horizontally, dates to the early 20th century and is a hallmark of modern spool design. Observing these evolutionary changes can narrow down the spool’s age range.

Finally, consider the patina and wear patterns. Antique spools often display a deep, natural patina from decades of exposure to air and handling. Look for signs of wear around the edges and holes, which indicate prolonged use. Spools with paint or varnish that is cracked or flaking are likely older, as modern finishes tend to be more durable. However, be cautious of spools that appear artificially aged, as some reproductions mimic wear to deceive collectors. A genuine antique spool will have a consistent, natural aging process that reflects its history.

By combining these observations—material, markings, design, and patina—you can piece together the age of a wooden thread spool with reasonable accuracy. Each feature tells a part of the story, and together, they reveal the spool’s place in the timeline of textile history. Whether you’re a collector or a history enthusiast, these key features transform a simple spool into a tangible link to the past.

Does Old Wood Not Pop? Unraveling the Myth of Aging Timber

You may want to see also

Explore related products

Material Aging: How wood deteriorates over time on spools

Wooden thread spools, often cherished for their rustic charm and historical significance, are susceptible to the relentless forces of material aging. The deterioration of wood over time is a complex process influenced by environmental factors, inherent material properties, and mechanical stress. Understanding these mechanisms is crucial for preserving both the functionality and aesthetic appeal of these artifacts.

Analytical Insight: Wood degradation on spools primarily occurs through three mechanisms: moisture absorption, UV exposure, and biological activity. Moisture, the most pervasive culprit, causes fibers to swell and contract, leading to cracks and warping. Prolonged exposure to sunlight accelerates this process by breaking down lignin, the natural glue that binds wood cells, resulting in discoloration and brittleness. Biological agents like fungi and insects further compromise structural integrity, particularly in spools stored in humid or untreated environments.

Instructive Guidance: To mitigate aging, store spools in a controlled environment with humidity levels between 40–50% and temperatures below 75°F (24°C). Apply a thin coat of linseed oil or beeswax annually to create a protective barrier against moisture and UV rays. For spools already showing signs of deterioration, gently sand affected areas and treat with a wood consolidant to stabilize fragile fibers. Avoid harsh chemicals or excessive polishing, as these can strip away protective layers and exacerbate damage.

Comparative Perspective: Unlike modern plastic spools, wooden spools age in a way that reflects their history and use. While plastic may become brittle or discolored, wood develops a patina that can enhance its value if properly maintained. However, this natural aging process requires proactive care, whereas plastic spools often demand less intervention. Collectors and enthusiasts must weigh the aesthetic appeal of wood against the maintenance it necessitates.

Descriptive Observation: Over decades, a wooden spool’s surface may develop fine cracks, known as checks, radiating from the center hole. The once-smooth texture becomes rough, and the color deepens to a rich, amber hue. In advanced cases, the wood may shrink unevenly, causing the thread grooves to distort. These changes are not merely signs of decay but a narrative of the spool’s journey through time, each mark a testament to its endurance.

Practical Takeaway: Regular inspection is key to preserving wooden spools. Look for early signs of mold, insect boreholes, or unusual softness in the wood. For spools of significant age or value, consult a conservator for specialized treatments like freeze-drying or resin infiltration. By understanding and addressing the specific vulnerabilities of wood, enthusiasts can ensure these artifacts remain both functional and beautiful for generations to come.

Does Wood Decay in Aging Homes? Understanding Old House Maintenance

You may want to see also

Explore related products

Collectors' Insights: Expert tips for dating wooden thread spools

Wooden thread spools, often overlooked relics of domestic history, hold clues to their age through subtle details that only a discerning eye can interpret. One of the first steps in dating these artifacts is examining the wood itself. Early spools, particularly those from the 19th century, were typically crafted from hardwoods like maple or birch, which were abundant and durable. Later spools, especially post-1900, often used softer woods like pine or even composite materials, reflecting changes in manufacturing practices and resource availability. A simple tactile test—feeling the grain and density—can provide an initial age estimate.

Another critical factor is the presence or absence of a metal insert in the spool’s center. Spools with metal inserts, usually made of brass or steel, date primarily to the late 19th and early 20th centuries. These inserts were designed to prevent thread from fraying and were a hallmark of higher-quality spools. By contrast, spools without metal inserts, often with a simple wooden dowel, are generally older, predating the 1880s. This distinction can narrow down a spool’s age range significantly, especially when combined with other indicators.

The design and typography on the spool’s label offer further insights. Early spools, particularly those from the mid-19th century, often featured hand-painted or stenciled labels with minimal information, such as the thread size or manufacturer’s name. As printing technology advanced, labels became more intricate, with detailed logos, patents, and even advertising slogans. For instance, spools with patent dates (e.g., “Patented 1878”) can be dated precisely to the post-patent period. Analyzing the font style, ink quality, and label placement can also reveal manufacturing trends tied to specific eras.

Condition and wear patterns are equally telling. Spools with significant wear, such as smoothed edges or faded labels, likely saw decades of use and are probably older than those in pristine condition. However, caution is warranted: some spools were never used and remained in storage, retaining their original appearance despite their age. Cross-referencing wear with other dating methods, such as wood type and label design, can help avoid misidentification.

Finally, provenance plays a crucial role in dating wooden thread spools. Spools found in estates or collections with documented histories can often be dated more accurately than isolated finds. For example, a spool discovered in a trunk with clothing from the 1890s is likely contemporaneous with those garments. While provenance isn’t always available, when it is, it can provide a definitive anchor for age estimation. Combining these expert tips—wood type, metal inserts, label design, wear, and provenance—allows collectors to unlock the stories hidden within these unassuming objects.

Ronnie Wood's Age: Unveiling the Rolling Stone's Timeless Journey

You may want to see also

Explore related products

Preservation Methods: Best practices to maintain spool longevity

Wooden thread spools, often cherished for their historical and aesthetic value, require careful preservation to ensure their longevity. Exposure to environmental factors like moisture, sunlight, and pests can accelerate deterioration, making proactive measures essential. Understanding the vulnerabilities of wood and thread materials is the first step in crafting an effective preservation strategy.

Analytical Insight: Wood is hygroscopic, meaning it absorbs and releases moisture based on ambient conditions. Fluctuations in humidity can cause warping, cracking, or mold growth. Thread, particularly natural fibers like cotton or silk, is susceptible to degradation from UV light and insects. Preservation methods must address both material-specific risks while maintaining the spool’s structural integrity and appearance.

Instructive Steps: To preserve wooden thread spools, begin by controlling their environment. Store them in a climate-controlled space with humidity levels between 40–50% and temperatures around 68–72°F (20–22°C). Use silica gel packets to regulate moisture, replacing them every 3–6 months. Avoid direct sunlight by storing spools in opaque containers or drawers. For added protection, wrap each spool in acid-free tissue paper to prevent dust accumulation and minimize friction between spools.

Comparative Cautions: While some collectors advocate for varnishing or waxing wooden spools to enhance durability, these methods can alter the spool’s patina and historical authenticity. Varnish may yellow over time, and wax can attract dust. Instead, opt for non-invasive treatments like applying a thin coat of archival-grade wax-resin blend, which provides protection without compromising the spool’s original character. For thread preservation, avoid synthetic materials that can degrade over time; stick to natural, untreated fibers.

Descriptive Takeaway: Properly preserved wooden thread spools retain their charm and functionality for generations. Imagine a 100-year-old spool, its wood still smooth and thread vibrant, thanks to consistent care. By prioritizing environmental control, minimal intervention, and material-specific treatments, you ensure these artifacts remain both beautiful and usable. Preservation is not just about longevity—it’s about honoring the craftsmanship and history embodied in each spool.

Apricot Trees: New or Old Wood for Fruit Production?

You may want to see also

Frequently asked questions

Wooden thread spools date back to the early 19th century, with many surviving examples from the mid-1800s to the early 1900s.

Yes, wooden thread spools made before the 1930s are often considered antiques, especially those with original labels or unique designs.

Age can be estimated by examining the manufacturer’s markings, the type of wood, the design, and the presence of patents or dates stamped on the spool.

Older wooden thread spools, especially those in good condition or from well-known manufacturers, can be valuable to collectors, with prices ranging from a few dollars to over $100.

Yes, wooden thread spools were largely replaced by plastic spools in the mid-20th century due to the lower cost and durability of plastic.