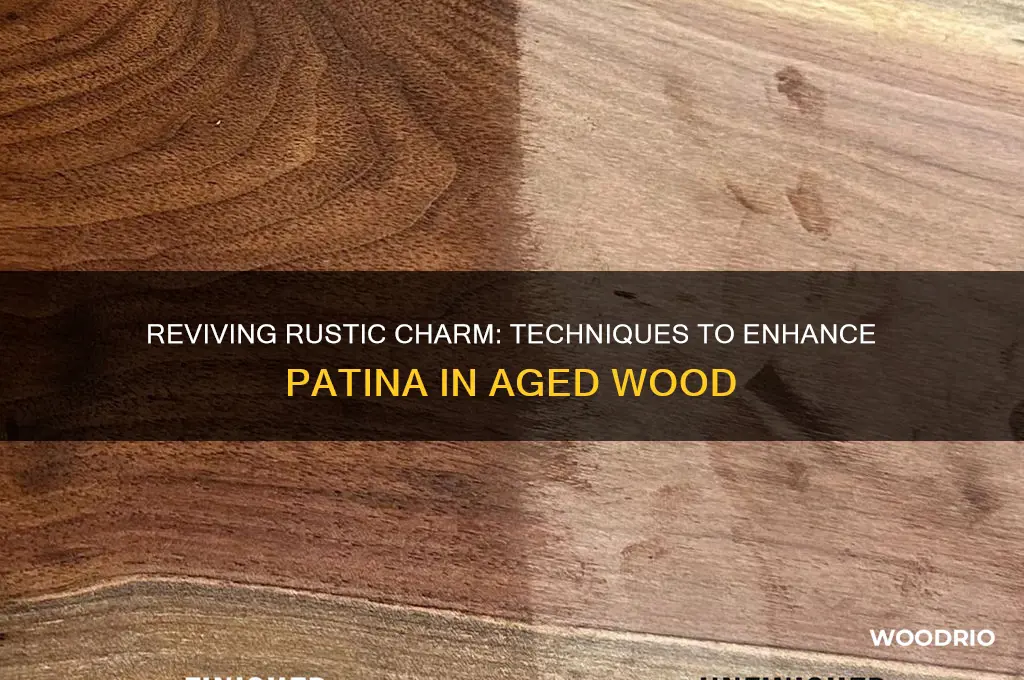

Bringing out the patina in old wood is an art that enhances its natural beauty and character, revealing the depth of its history and craftsmanship. Patina, the unique sheen and texture that develops over time due to age, wear, and exposure, adds warmth and authenticity to wooden pieces. To highlight this patina, start by gently cleaning the wood to remove dirt and grime without stripping away its natural finish. Techniques such as using mild soap and water, or a mixture of vinegar and olive oil, can help restore its luster. Lightly sanding the surface with fine-grit sandpaper can also accentuate the grain and texture, while applying a thin coat of wax or oil can deepen the color and protect the wood. The goal is to preserve and enhance the wood’s aged appearance, allowing its story to shine through while maintaining its integrity.

| Characteristics | Values |

|---|---|

| Cleaning | Start by gently cleaning the wood surface with a mild detergent and water solution to remove dirt, grime, and old finishes. Avoid harsh chemicals that can damage the wood. |

| Sanding | Lightly sand the wood surface with fine-grit sandpaper (220-grit or higher) to remove any remaining finish and smooth out imperfections. Be careful not to sand too aggressively, as this can remove the patina. |

| Wire brushing | Use a wire brush to gently scrub the wood surface, following the grain. This helps to raise the grain and bring out the natural patina. |

| Chemical treatments | Apply a patina-enhancing solution, such as a mixture of vinegar and steel wool, or a commercial patina accelerator, to the wood surface. These solutions react with the tannins in the wood to create a darker, richer patina. |

| Natural aging | Expose the wood to natural elements like sunlight, humidity, and temperature changes to accelerate the aging process and bring out the patina. This method takes time but produces authentic results. |

| Heat treatment | Apply heat to the wood surface using a heat gun or torch to darken and enrich the patina. Be cautious when using heat, as it can damage the wood if not applied properly. |

| Oil or wax finish | Apply a thin coat of tung oil, linseed oil, or wax to the wood surface to enhance and protect the patina. These finishes penetrate the wood, bringing out the natural colors and grain patterns. |

| Time and patience | Bringing out the patina in old wood is a gradual process that requires time and patience. Avoid rushing the process, as this can lead to uneven or unnatural results. |

| Testing | Test any treatments or finishes on a small, inconspicuous area of the wood before applying them to the entire surface. This helps to ensure that the desired results are achieved without damaging the wood. |

| Maintenance | Regularly clean and maintain the wood surface to preserve the patina and prevent damage. Avoid using harsh chemicals or abrasive cleaners that can strip away the patina. |

Explore related products

What You'll Learn

- Wire Brush Technique: Use a wire brush to gently remove dirt and reveal wood grain

- Vinegar and Steel Wool: Apply vinegar-soaked steel wool to create a natural aged patina

- Sandpaper Grading: Gradually sand with finer grits to expose deeper wood layers

- Ammonia Fuming: Controlled ammonia exposure darkens wood for an antique appearance

- Natural Weathering: Expose wood to sunlight and moisture for organic patina development

Wire Brush Technique: Use a wire brush to gently remove dirt and reveal wood grain

The wire brush technique is a delicate dance between preservation and restoration, ideal for old wood that has accumulated layers of dirt, grime, or old finishes without obscuring its natural patina. Unlike sanding, which can strip away the very character you aim to highlight, a wire brush works selectively. Its stiff bristles target surface contaminants while leaving the wood’s aged texture intact. This method is particularly effective on weathered barnwood, antique furniture, or reclaimed beams where the goal is to refresh, not refinish.

Begin by selecting the right wire brush. For finer, more delicate wood grains, opt for a brass-bristled brush, which is less abrasive than steel. For tougher, more resilient surfaces, a stainless steel brush provides the necessary grit to dislodge stubborn dirt. Handheld brushes offer precision, while power drill attachments expedite the process for larger areas. Always test a small, inconspicuous section first to gauge the wood’s reaction and adjust pressure accordingly.

Technique matters. Hold the brush at a shallow angle to the wood surface, working in the direction of the grain. Apply firm but controlled pressure, letting the bristles do the work rather than forcing them. Circular motions can help dislodge dirt in stubborn crevices, but linear strokes are generally more effective for consistent results. Avoid over-brushing, as this can create uneven wear or expose raw wood beneath the patina. The goal is to clean, not to carve.

Post-brushing care is crucial. Once the dirt is removed, wipe the surface with a tack cloth to capture loose particles, followed by a soft brush to ensure no metal bristles are left behind. If desired, apply a thin coat of linseed oil or wax to nourish the wood and enhance its natural luster without altering its aged appearance. This step not only protects the wood but also deepens the patina, making the grain pop while preserving its history.

The wire brush technique is a testament to the principle of "less is more" in restoration. It respects the wood’s story, allowing its age and character to shine through without erasing the marks of time. When executed thoughtfully, it transforms neglected wood into a centerpiece that feels both timeless and alive, a bridge between the past and the present.

Kelly Wood Thompson's Age: Unveiling the Mystery Behind Her Years

You may want to see also

Explore related products

Vinegar and Steel Wool: Apply vinegar-soaked steel wool to create a natural aged patina

The chemical reaction between vinegar and steel wool mimics the natural aging process of wood, offering a controlled way to achieve a patina without decades of waiting. This method leverages acetic acid in vinegar to etch the wood surface, while the steel wool’s iron particles react with tannins in the wood to create a darkened, weathered appearance. It’s a technique favored by restoration experts and DIY enthusiasts alike for its simplicity and effectiveness.

To begin, gather white vinegar (5% acetic acid), fine-grade steel wool (0000), gloves, and a clean cloth. For every 1 cup of vinegar, add 1 tablespoon of salt to accelerate the reaction, though this step is optional. Soak the steel wool in the vinegar solution for at least 24 hours, allowing the mixture to oxidize and turn darker. The longer the soak, the stronger the solution, but 24–48 hours is typically sufficient. Test the solution on a scrap piece of wood or an inconspicuous area to gauge its strength and effect.

Application requires patience and precision. Wearing gloves, rub the vinegar-soaked steel wool along the wood grain in circular motions. Focus on areas where natural wear would occur, such as edges, corners, and surfaces prone to touch. The wood will initially lighten due to the acid etching, but as it dries, the iron particles react with tannins to produce a grayish-brown patina. For deeper color, apply multiple layers, allowing the wood to dry completely between applications. Seal the final result with a matte finish to preserve the patina without altering its appearance.

While effective, this method has limitations. It works best on woods high in tannins, like oak or walnut, and may yield uneven results on softer woods like pine. Over-application can lead to a blotchy appearance or excessive darkening, so moderation is key. Always work in a well-ventilated area, as the vinegar fumes can be strong, and avoid using this technique on painted or finished surfaces unless you intend to strip them first.

In comparison to other patina methods, such as tea staining or ammonia fuming, vinegar and steel wool offers a more controlled and predictable outcome. It’s less toxic than ammonia and more versatile than tea, which tends to produce a uniform color. For those seeking a natural, aged look without the wait, this method strikes a balance between chemistry and craftsmanship, turning raw wood into a timeless piece with minimal effort.

Can Sage Thrive on Aging Wood? Uncovering the Truth

You may want to see also

Explore related products

$29.5

Sandpaper Grading: Gradually sand with finer grits to expose deeper wood layers

The art of sandpaper grading is a delicate dance, where each step reveals a new layer of history hidden within the wood's surface. Imagine a centuries-old oak beam, its surface weathered by time, each scratch and dent telling a story. To bring out its patina, you must become an archaeologist of sorts, carefully excavating the past with sandpaper as your tool. Start with a coarse grit, say 80 or 100, to remove the top layer of dirt, grime, and old finishes. This initial pass is like brushing away the soil to uncover the first clues of a buried treasure.

As you progress, the choice of grit becomes more critical. A 150-grit sandpaper is ideal for smoothing out the initial scratches, preparing the wood for a more refined touch. This stage requires patience; rushing might remove too much material, erasing the very character you aim to reveal. Think of it as a sculptor shaping marble, where each stroke must be deliberate and controlled. The goal is not to create a flawless surface but to enhance the wood's natural beauty, allowing its age and uniqueness to shine through.

The transformation becomes more apparent with each finer grit. Moving to 220 and then 320 grit, you'll notice the wood's texture changing, becoming smoother yet retaining its aged charm. This gradual process is akin to polishing a gem, where the true brilliance emerges only after multiple stages of refinement. For particularly old or delicate wood, consider using a 400-grit sandpaper for the final pass, ensuring a silky finish that highlights the patina without compromising the wood's integrity.

However, this technique is not without its challenges. Over-sanding can lead to a loss of character, leaving the wood looking new and generic. It's a fine line to tread, especially with antique pieces where every mark is a testament to their longevity. Always sand in the direction of the wood grain to avoid creating unsightly scratches. Additionally, keep the wood's moisture content in mind; sanding dry wood can raise the grain, requiring an additional step of dampening the surface before the final sanding.

In the pursuit of the perfect patina, sandpaper grading is both a science and an art. It demands respect for the material, an understanding of its history, and a keen eye for detail. By gradually working through the grits, you're not just sanding wood; you're uncovering a narrative, layer by layer, until the wood's true character is revealed in all its aged glory. This method ensures that the final piece not only looks authentic but also tells a story that only time could have written.

Reviving Your Banjo: Expert Tips to Adjust Old Neck Wood

You may want to see also

Explore related products

$29.95

Ammonia Fuming: Controlled ammonia exposure darkens wood for an antique appearance

Ammonia fuming is a time-honored technique that leverages the chemical reaction between ammonia and the tannins in wood to create a rich, aged patina. This method, often used by craftsmen and restoration experts, can transform new or lightly weathered wood into a piece that appears centuries old. The process involves exposing the wood to ammonia fumes in a controlled environment, allowing the gas to penetrate the surface and react with the natural tannins, resulting in a darkened, antique appearance.

To begin ammonia fuming, prepare your workspace by ensuring proper ventilation and safety measures. Ammonia is caustic and can be harmful if inhaled, so work in a well-ventilated area or use a fuming tent. Wear protective gear, including gloves, goggles, and a respirator. Dilute household ammonia (typically 5-10% concentration) with water in a ratio of 1:1 for a milder effect, or use it undiluted for a more pronounced darkening. Place the wood in a sealed container, add the ammonia solution to a shallow dish, and close the container to trap the fumes. Exposure time varies—30 minutes to several hours—depending on the desired depth of color and the wood species. Oak, chestnut, and walnut, which are high in tannins, respond particularly well.

The science behind ammonia fuming lies in its interaction with tannins, naturally occurring compounds in wood that react with ammonia to form a dark, insoluble compound. This reaction mimics the natural aging process, where wood darkens over time due to exposure to air, moisture, and light. Unlike staining, which sits on the surface, ammonia fuming penetrates the wood, creating a more authentic and durable patina. However, not all woods contain enough tannins to react effectively; test a small sample before treating an entire piece.

One practical tip is to pre-treat the wood with a tannic acid solution to enhance the reaction, especially if the wood’s natural tannin content is low. Apply a mixture of tannic acid and water (1 tablespoon per cup of water) to the wood, let it dry, and then proceed with fuming. This step ensures a more uniform and intense darkening. Additionally, after fuming, neutralize the ammonia residue by wiping the wood with a vinegar solution (equal parts vinegar and water) to prevent further chemical reactions.

While ammonia fuming is effective, it’s not without risks. Over-exposure can lead to uneven darkening or a greenish tint, particularly in woods with lower tannin content. Always monitor the process closely and be prepared to stop the reaction by removing the wood from the fuming container. Despite these cautions, when executed carefully, ammonia fuming remains a powerful technique for achieving an authentic antique patina, blending art, chemistry, and craftsmanship into a single transformative process.

New vs. Old Wood: Where Do Apples Actually Grow?

You may want to see also

Explore related products

Natural Weathering: Expose wood to sunlight and moisture for organic patina development

Sunlight and moisture are nature’s artists, capable of transforming raw wood into a masterpiece of patina over time. This process, known as natural weathering, relies on the wood’s exposure to the elements to break down its surface, soften its texture, and deepen its color. Unlike chemical treatments or mechanical distressing, natural weathering yields a patina that feels authentically aged, with variations that mimic decades of use and exposure. The key lies in patience, as this method can take months or even years to achieve the desired effect, but the result is a uniquely organic and irreplaceable finish.

To begin, select a piece of wood that is suitable for outdoor exposure. Hardwoods like oak, teak, or cedar are ideal due to their durability and natural resistance to decay. Place the wood in a location where it will receive consistent sunlight and occasional moisture, such as a porch, garden, or even a windowsill with rain exposure. The UV rays in sunlight break down the wood’s lignin, causing it to lighten initially before gradually darkening as tannins oxidize. Moisture, on the other hand, raises the wood grain and encourages the growth of surface textures like checking and cracking, adding depth to the patina. Aim for at least 6–8 hours of sunlight daily and ensure the wood gets wet periodically, either from rain or manual watering.

While the process is largely hands-off, there are ways to accelerate or guide the patina development. For instance, lightly sanding the wood before exposure can remove the factory finish and allow the elements to penetrate more quickly. Applying a thin coat of linseed oil or vinegar can also enhance the wood’s reaction to moisture, encouraging darker, richer tones. However, avoid over-treating the wood, as the goal is to let nature take the lead. Monitor the wood’s progress monthly, noting changes in color, texture, and grain pattern. If mold appears, gently scrub the surface with a mixture of water and mild detergent to prevent it from marring the patina.

One of the most compelling aspects of natural weathering is its unpredictability. Each piece of wood will develop its own unique character based on its species, density, and the specific environmental conditions it encounters. For example, wood exposed to saltwater will develop a distinct grayish hue, while inland pieces may take on warmer, amber tones. This variability is part of the charm, as it ensures no two patinas are alike. For those seeking a more controlled outcome, consider experimenting with smaller wood samples before committing to larger projects.

In conclusion, natural weathering is a testament to the beauty of time and patience. By exposing wood to sunlight and moisture, you allow it to evolve naturally, creating a patina that tells a story of endurance and transformation. While the process requires commitment, the reward is a finish that cannot be replicated artificially—a true marriage of craftsmanship and nature’s artistry. Whether you’re restoring an antique or aging new wood, this method offers a timeless and sustainable way to bring out the wood’s inherent character.

Were Ft. Hood's Old Wooden Barricades Effective in Ensuring Safety?

You may want to see also

Frequently asked questions

Patina is the natural aging and wear that occurs on wood over time, resulting in a unique, weathered appearance. It is desirable because it adds character, depth, and a sense of history to the wood, enhancing its aesthetic appeal.

Gently clean the wood with a mild soap and water solution to remove dirt and grime, then apply a mixture of vinegar and steel wool to naturally darken and bring out the patina. Avoid harsh chemicals or excessive sanding.

Yes, you can simulate patina by using techniques like distressing, applying vinegar or tea stains, or using wire brushes to create texture. Seal with a wax or oil finish to preserve the look.

Use fine-grit sandpaper, steel wool, natural oils (like linseed or tung oil), vinegar, and soft brushes. These tools help reveal and enhance the wood’s natural aging without causing damage.

Apply a thin coat of wax, tung oil, or a matte polyurethane finish to seal and protect the wood while preserving its natural patina. Avoid glossy finishes, as they can detract from the aged appearance.

![Furniture Glaze - Antique Patina Special Effects Glaze for Chalk Style Furniture Paint, Eco-Friendly Wood Stain, 6 Color Choices - Smoky Quartz [Chocolate Brown] - (4 oz)](https://m.media-amazon.com/images/I/71L+n7xDt+L._AC_UL320_.jpg)