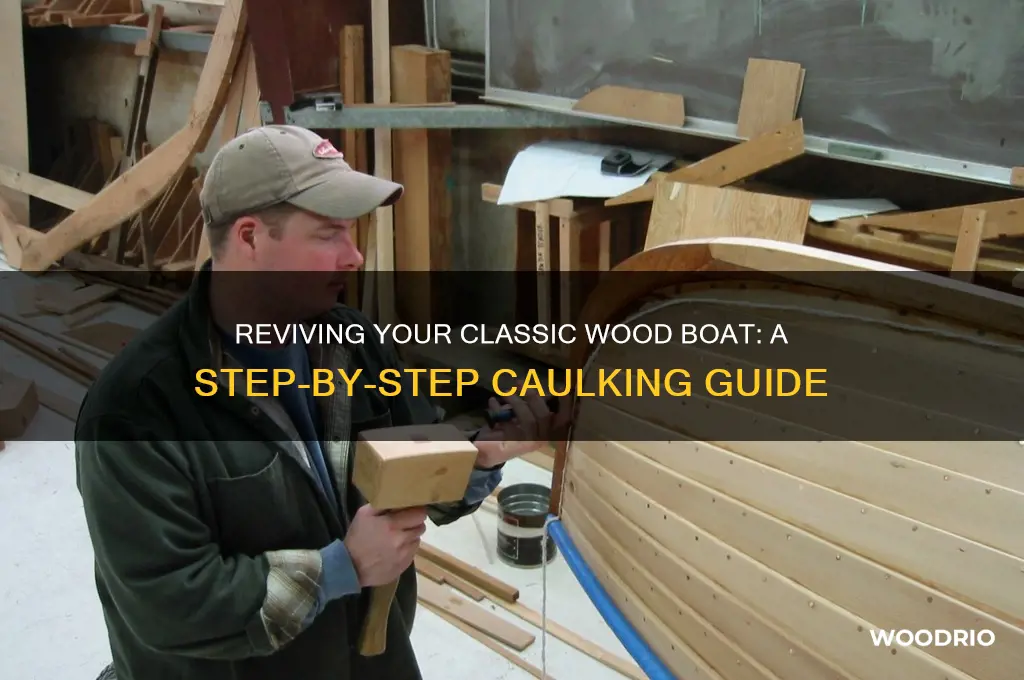

Caulkinga classic wood boat is a crucial skill for any maritime enthusiast looking to preserve its integrity and seaworthiness. Over time, the natural expansion and contraction of wood, coupled with exposure to water and weather, can cause seams to open, allowing moisture to penetrate and weaken the structure. Proper caulking involves carefully removing old, deteriorated material, cleaning the seams, and applying new cotton or fiber caulking, followed by sealing it with a marine-grade compound. This process not only prevents leaks but also ensures the boat remains sturdy and safe for years to come, blending traditional craftsmanship with practical maintenance.

Explore related products

What You'll Learn

- Prepare the Surface: Clean, sand, and dry the wood to ensure proper caulk adhesion

- Choose the Right Caulk: Select marine-grade caulk suitable for wood and weather conditions

- Apply Caulk Properly: Use a caulking gun, smooth beads, and remove excess immediately

- Seal Seams and Cracks: Focus on gaps, joints, and areas prone to water intrusion

- Cure and Maintain: Allow caulk to cure fully and inspect regularly for wear

Prepare the Surface: Clean, sand, and dry the wood to ensure proper caulk adhesion

Before applying caulk to an old wood boat, the surface must be meticulously prepared to ensure longevity and effectiveness. Wood, especially aged wood, accumulates dirt, grime, and old sealant residues that can compromise adhesion. Start by cleaning the area with a marine-grade cleaner or a mixture of mild detergent and water. Use a stiff brush to scrub away stubborn debris, paying special attention to seams and crevices where dirt tends to accumulate. Rinse thoroughly with fresh water and allow the wood to dry completely, as moisture trapped beneath the caulk can lead to rot or mold.

Sanding is the next critical step in surface preparation. Use 80-grit sandpaper to remove old caulk, paint, or varnish, ensuring the wood is bare and roughened for optimal adhesion. For tighter areas, a sanding sponge or block can provide better control. Once the initial sanding is complete, switch to 120-grit sandpaper to smooth the surface further, creating a uniform texture. Wipe away all dust with a tack cloth or a damp rag, ensuring no particles remain that could interfere with the caulk’s bond.

Drying the wood thoroughly cannot be overstated. Even small amounts of moisture can undermine the caulk’s ability to adhere properly. If the boat has been exposed to rain or high humidity, allow it to air dry for at least 48 hours in a well-ventilated area. For faster results, use a heat gun or hairdryer on a low setting, being careful not to scorch the wood. A moisture meter can be a valuable tool to confirm the wood’s dryness, with ideal moisture content below 15% for most caulking applications.

Consider the environmental conditions during preparation. Avoid working in direct sunlight or extreme temperatures, as these can cause the wood to expand or contract, affecting the caulk’s performance. If the boat is stored outdoors, cover the work area with a tarp to protect it from dew or unexpected rain. Proper surface preparation is time-consuming but essential—it’s the foundation upon which the caulk’s durability and effectiveness rest.

Finally, inspect the prepared surface for any imperfections or missed spots. Run your hand along the wood to feel for rough patches or residual debris. If necessary, repeat the cleaning or sanding process until the surface is flawless. This meticulous attention to detail ensures the caulk adheres uniformly, preventing leaks and extending the life of your boat’s wooden structure. Skipping or rushing this step can lead to costly repairs down the line, making it a non-negotiable part of the caulking process.

Gene Woods Atrium Health: Unveiling the Age and Legacy

You may want to see also

Explore related products

Choose the Right Caulk: Select marine-grade caulk suitable for wood and weather conditions

Marine-grade caulk isn’t just a generic sealant—it’s engineered to withstand the relentless assault of saltwater, UV rays, and temperature extremes. Unlike standard household caulk, marine variants contain additives like UV stabilizers and mildew inhibitors, ensuring longevity in harsh environments. For wooden boats, flexibility is key; wood expands and contracts with moisture, so choose a caulk that moves with it, not against it. Polyurethane or silicone-based sealants are often ideal, as they remain pliable and resist cracking over time.

Selecting the right caulk begins with assessing your boat’s specific needs. Is it a freshwater vessel or exposed to saltwater? Does it face intense sun or frequent rain? For saltwater environments, opt for a caulk labeled "saltwater-resistant" to prevent degradation. If your boat sits in direct sunlight, prioritize UV-resistant formulas to avoid discoloration and brittleness. Always check the manufacturer’s guidelines for compatibility with wood species and weather conditions—a mismatch can lead to adhesion failure or premature wear.

Application technique matters as much as the product itself. Clean the surface thoroughly, removing old caulk, dirt, and debris with a scraper and solvent. Apply the caulk in a consistent bead, using a caulking gun with steady pressure. For narrow seams, a 1/4-inch bead is often sufficient; wider gaps may require a 3/8-inch bead. Smooth the caulk with a damp finger or tool, ensuring it adheres evenly to both surfaces. Allow ample curing time—typically 24–48 hours—before exposing the boat to water.

Not all marine caulks are created equal, and cost doesn’t always correlate with quality. Premium brands like 3M Marine Adhesive Sealant 5200 offer superior adhesion and durability but can be challenging to remove if mistakes occur. Mid-range options like Sikaflex-291 provide a balance of performance and ease of use. For budget-conscious projects, consider BoatLIFE’s Life Seal, which performs well in moderate conditions. Always weigh the trade-offs: easier application versus long-term resilience, cost versus longevity.

Finally, consider the environmental impact of your choice. Traditional caulks may contain volatile organic compounds (VOCs) harmful to marine life. Opt for low-VOC or eco-friendly alternatives like TotalBoat Silicone Sealant, which minimizes ecological harm without sacrificing performance. Proper disposal of old caulk and packaging is equally important—many marine supply stores offer recycling programs for hazardous materials. By choosing responsibly, you protect both your boat and the waters it sails.

Unveiling the Ancient Age of Eastern Oregon's Petrified Wood

You may want to see also

Explore related products

Apply Caulk Properly: Use a caulking gun, smooth beads, and remove excess immediately

Applying caulk to an old wood boat requires precision and the right tools. Start with a high-quality caulking gun, ensuring it’s compatible with marine-grade caulk. Load the caulk tube into the gun, cut the nozzle at a 45-degree angle, and puncture the inner seal. This setup allows for controlled dispensing, which is critical for achieving consistent beads along seams and planking. A steady hand and even pressure on the trigger will prevent gaps or over-application, laying the foundation for a watertight seal.

Smoothing the caulk beads is an art that transforms functionality into craftsmanship. Use a dampened finger or a caulking tool to press the caulk firmly into the seam, creating a concave profile that enhances adhesion and reduces surface tension. For larger gaps, apply caulk in layers, allowing each to set slightly before adding more. This technique ensures the caulk penetrates deeply without trapping air pockets. The goal is a seamless integration that mimics the boat’s original construction, preserving both aesthetics and structural integrity.

Removing excess caulk immediately is non-negotiable. Letting it dry complicates cleanup and risks unsightly residue. Keep a damp cloth or sponge nearby to wipe away overages as you work, focusing on edges and transitions. For stubborn spots, mineral spirits or a specialized caulk remover can be used, but test on a small area first to avoid damaging the wood. Prompt removal not only ensures a professional finish but also prevents caulk from hardening in unwanted areas, which could compromise the seal.

Mastering these steps—using a caulking gun, smoothing beads, and removing excess—elevates caulking from a chore to a skill. It’s the difference between a temporary fix and a lasting repair. For older boats, this attention to detail honors their craftsmanship while safeguarding them for future voyages. With practice, the process becomes intuitive, blending efficiency with precision to restore both form and function.

James Woods' Age and Relationship: Unveiling His Life and Love

You may want to see also

Explore related products

Seal Seams and Cracks: Focus on gaps, joints, and areas prone to water intrusion

Water intrusion is the silent killer of wooden boats, and seams and cracks are its favorite entry points. Left unchecked, these vulnerabilities allow moisture to seep in, leading to rot, delamination, and structural compromise. Identifying and sealing these weak spots is a critical step in preserving your boat's integrity.

Inspect your boat meticulously, focusing on areas where wood meets wood, hardware penetrates the hull, and around fasteners. Look for hairline fractures, widened seams, and any signs of previous, failed caulking. Pay particular attention to the gunwales, stem, transom, and any areas subjected to constant flexing or movement.

The key to successful sealing lies in choosing the right caulk and applying it correctly. For most wooden boats, a flexible, marine-grade polysulfide or silicone sealant is ideal. These materials adhere well to wood, remain pliable over time, and resist the harsh marine environment. Avoid traditional oakum and cotton caulking, which are labor-intensive and prone to shrinkage. Before applying caulk, ensure the surfaces are clean, dry, and free of old sealant. Use a putty knife or scraper to remove any debris, and consider sanding rough areas for better adhesion.

Application technique is crucial. Cut the caulk tube nozzle at a 45-degree angle for precise control. Apply a generous bead of caulk along the seam, using a caulking gun with steady pressure. For wider gaps, use a backing material like cotton cord or fiberglass tape to prevent the caulk from sinking too deeply. Smooth the caulk with a damp finger or a caulking tool, ensuring a uniform seal that fills the entire void.

Remember, caulking is not a one-time fix. Regular inspection and maintenance are essential. Check your seals annually, reapplying caulk as needed. By diligently sealing seams and cracks, you'll safeguard your wooden boat against the relentless assault of water, ensuring its beauty and seaworthiness for years to come.

Amanda Woods' Age: Unveiling the Mystery Behind Her Birth Year

You may want to see also

Explore related products

Cure and Maintain: Allow caulk to cure fully and inspect regularly for wear

After applying caulk to your old wood boat, patience becomes your most valuable tool. Caulk, particularly marine-grade varieties like Sikaflex or 3M 5200, requires time to cure fully—often 24 to 48 hours for surface dryness, but up to 7 days for complete curing, depending on humidity and temperature. Rushing this process risks weakened seals and compromised waterproofing. During curing, avoid exposing the caulked areas to water or heavy use, as this can dislodge the material or trap moisture beneath the surface, leading to rot or mold. Think of curing as the foundation of your repair; skimp on time here, and the entire job suffers.

Once cured, maintenance shifts from passive waiting to active vigilance. Inspect caulked seams seasonally, or more frequently if the boat is in constant use or exposed to harsh conditions. Look for cracks, shrinkage, or areas where the caulk has pulled away from the wood. These signs indicate wear and potential leaks. For example, if you notice a hairline crack along a seam, don’t ignore it—even small breaches can allow water to penetrate, swelling the wood and exacerbating the problem. Use a bright LED light or magnifying glass to spot subtle issues, and address them immediately with a touch-up application.

Comparing caulk maintenance to car tire care can be instructive. Just as tires need regular checks for wear and pressure, caulk requires routine inspection to ensure longevity. Tires lose pressure over time, and caulk degrades under UV exposure, temperature fluctuations, and mechanical stress. Both demand proactive attention to prevent failure. While a blown tire strands you on the road, failed caulk strands your boat in the water—literally. Treat caulk maintenance as a non-negotiable part of boat ownership, not an optional chore.

Practical tips can streamline this process. Keep a caulk inspection log, noting dates, conditions, and any issues found. Store spare caulk and tools onboard for quick repairs. For older boats, consider using a flexible wood sealant like epoxy-based caulks, which adhere better to aged wood fibers. When inspecting, run your finger along seams to detect subtle gaps or softness. If the caulk feels tacky or compresses easily, it may not have cured properly or could be failing. Finally, pair inspections with other maintenance tasks, like cleaning or varnishing, to make the routine more efficient and less daunting.

In conclusion, curing and maintaining caulk on an old wood boat is a blend of science and habit. Allow ample time for curing, inspect rigorously, and address issues promptly. By treating caulk care as a critical component of boat preservation, you ensure not just a watertight seal, but a vessel that endures the test of time and tides.

Alberta's Petrified Wood: Unveiling the Ancient Age of Fossilized Trees

You may want to see also

Frequently asked questions

Use a marine-grade silicone or polysulfide caulk, as they are flexible, waterproof, and resistant to UV rays and saltwater, making them ideal for wooden boats.

Clean the seams thoroughly by removing old caulk, dirt, and debris using a scraper, wire brush, or sandpaper. Ensure the wood is dry and free of moisture before applying new caulk.

Yes, stuffing the seams with oakum or cotton rope helps create a solid base for the caulk, improves adhesion, and prevents the caulk from sinking too deeply into the wood.

Load the caulk into a caulking gun and apply a smooth, even bead along the seam. Use a damp finger or a caulking tool to press the caulk into the seam and create a uniform finish, ensuring it adheres properly to both sides of the wood.

![KLRStec Professional Caulking Tool [100% Stainless Steel] 4 in 1 Caulk Remover Tool Kit - Grout Remover and Finishing Tool – Professional Multitool for perfect Silicone Joints DIY Sealer and Scraper](https://m.media-amazon.com/images/I/81andfUYVPL._AC_UL320_.jpg)