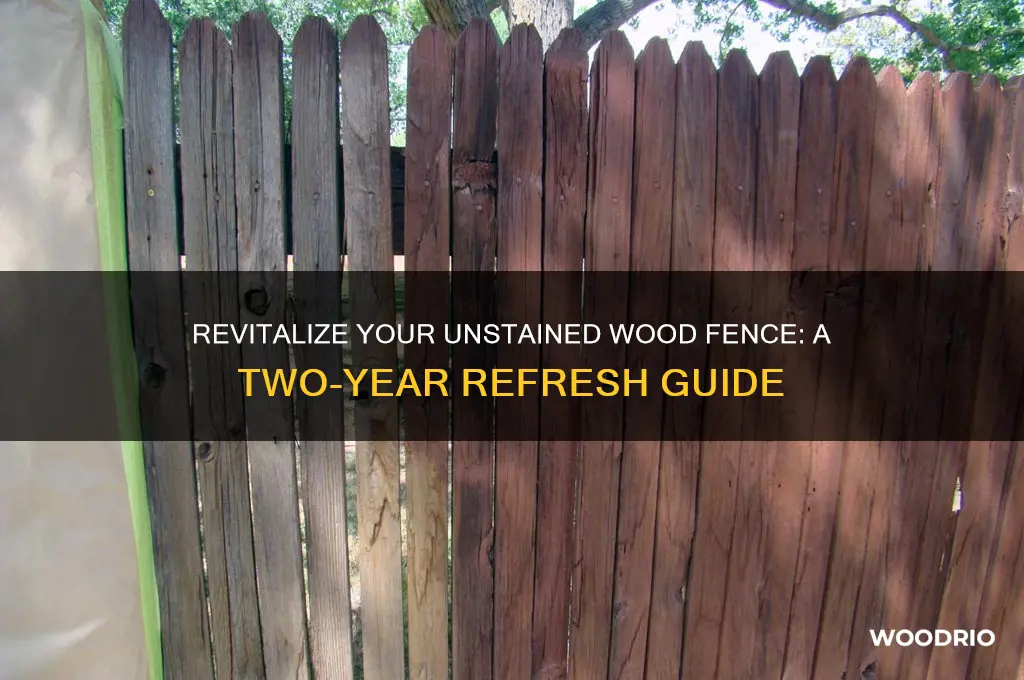

Changing a two-year-old unstained wood fence involves several key steps to ensure durability and aesthetic appeal. Begin by inspecting the fence for any damage, such as loose boards, splinters, or rot, and replace or repair these sections as needed. Next, clean the fence thoroughly using a mild detergent and water solution to remove dirt, mildew, or debris, and allow it to dry completely. Lightly sand the surface to smooth out rough areas and create a better surface for stain adhesion. Choose a high-quality wood stain or sealant suitable for outdoor use, applying it evenly with a brush, roller, or sprayer, following the manufacturer’s instructions. Finally, allow the stain to dry fully before reassembling any hardware or gates, ensuring the fence is both functional and protected for years to come.

| Characteristics | Values |

|---|---|

| Age of Fence | 2 years |

| Current Condition | Unstained |

| Material | Wood |

| Recommended Treatment | Stain or sealant application |

| Purpose of Treatment | Protect against weathering, UV damage, moisture absorption, and insect infestation |

| Types of Stains | Water-based, oil-based, semi-transparent, solid color |

| Preparation Steps | Clean the fence (pressure washing or scrubbing), allow to dry, sand rough areas, repair damages |

| Application Tools | Brush, roller, sprayer, pads |

| Drying Time | 24-48 hours (varies by product and weather conditions) |

| Maintenance Frequency | Reapply stain every 2-3 years, inspect annually |

| Environmental Considerations | Choose eco-friendly products, avoid application in direct sunlight or extreme temperatures |

| Safety Precautions | Wear protective gear (gloves, mask, goggles), ensure proper ventilation |

| Cost Estimate | $0.50 - $2.00 per square foot (materials and labor) |

| DIY vs. Professional | DIY possible with proper tools and preparation; professional recommended for large or complex fences |

| Longevity After Treatment | Extends fence life by 5-10 years depending on maintenance and environmental factors |

Explore related products

$28.43 $35.99

What You'll Learn

- Gather Tools & Materials: Hammer, nails, wood planks, gloves, safety gear, measuring tape, and a saw

- Inspect & Remove Old Fence: Check for damage, loosen posts, and carefully dismantle sections for replacement

- Prepare New Wood Planks: Measure, cut, and sand planks to fit; ensure smooth edges and proper alignment

- Install New Fence Sections: Secure posts, attach planks with nails, and ensure stability and straightness

- Seal & Protect the Fence: Apply wood sealant or stain to prevent weathering and extend fence life

Gather Tools & Materials: Hammer, nails, wood planks, gloves, safety gear, measuring tape, and a saw

Before embarking on the task of replacing a two-year-old unstained wood fence, it's crucial to assemble the right tools and materials to ensure efficiency and safety. The foundation of any successful fence repair or replacement project lies in having everything you need within arm's reach. A well-prepared toolkit not only saves time but also minimizes the risk of accidents or errors.

Analytical Perspective: The selection of tools and materials is not arbitrary; each item serves a specific purpose. For instance, a hammer and nails are essential for securing wood planks, while gloves and safety gear protect against splinters, sharp edges, and other hazards. A measuring tape ensures precise cuts and alignments, and a saw is indispensable for trimming planks to fit. Together, these items form a cohesive set that addresses every aspect of the task, from measurement and cutting to assembly and safety.

Instructive Approach: Begin by gathering your tools and materials in a designated workspace. Lay out the wood planks, ensuring they are free from defects and match the existing fence style. Check the hammer and nails for durability—opt for galvanized nails to prevent rust. Gloves should fit snugly to maintain dexterity, and safety gear, such as goggles and a dust mask, should meet industry standards. Measure the fence sections to determine the length of planks needed, and mark them clearly before cutting with the saw. This systematic approach ensures nothing is overlooked.

Comparative Insight: While it might be tempting to reuse old materials, investing in new, high-quality wood planks and tools can yield better long-term results. For example, fresh planks are less likely to warp or crack, and a sharp, well-maintained saw ensures cleaner cuts compared to a dull blade. Similarly, durable gloves and safety gear offer superior protection over worn-out alternatives. Though the initial cost may be higher, the longevity and ease of the finished fence justify the expense.

Descriptive Detail: Imagine your workspace: a clear area with tools neatly arranged and materials stacked in order. The hammer rests beside a box of nails, its handle smooth from use but still sturdy. Gloves lie nearby, their textured palms ready to grip planks securely. The measuring tape coils neatly, its markings crisp and easy to read. The saw stands ready, its blade gleaming under the sunlight. This organized setup transforms a daunting task into a manageable, even enjoyable, endeavor.

Practical Tips: Always prioritize safety by inspecting tools for damage before use. For instance, a cracked hammer handle or a bent nail can cause accidents. When measuring and cutting planks, double-check dimensions to avoid waste. Keep a bucket of water nearby when using power tools to minimize dust. Finally, store leftover materials properly for future repairs. These small precautions can significantly enhance both the process and the outcome of your fence replacement project.

Are Vintage Wooden Baseball Bats Valuable? A Collector's Guide

You may want to see also

Explore related products

Inspect & Remove Old Fence: Check for damage, loosen posts, and carefully dismantle sections for replacement

Before diving into the replacement of your two-year-old unstained wood fence, a thorough inspection is crucial. Start by examining each section for signs of damage, such as rot, warping, or insect infestation. Pay close attention to areas where the wood meets the ground, as these are most susceptible to moisture damage. Use a screwdriver to probe the wood; if it sinks in easily, the wood is likely compromised and needs replacement. This initial assessment will help you identify which parts of the fence require immediate attention and which can be salvaged.

Once you’ve identified the damaged sections, the next step is to loosen the fence posts. Begin by removing any attached rails or pickets using a pry bar or reciprocating saw. Be cautious not to damage the posts themselves, as you may need to reuse them if they’re still in good condition. For posts set in concrete, use a digging bar to break the soil away from the base and then pry the post loose. If the posts are stubborn, consider using a post puller tool, which provides mechanical advantage and reduces physical strain. Always work systematically, starting with one section at a time to maintain stability and safety.

Dismantling the fence requires precision to avoid unnecessary damage and ensure a smooth replacement process. Start by removing the nails or screws holding the pickets to the rails. A cat’s paw tool is ideal for extracting nails without splitting the wood. For sections with stubborn fasteners, apply penetrating oil and allow it to sit for 10–15 minutes before attempting removal. Once the pickets are free, carefully detach the rails from the posts. Stack and organize the salvaged materials for potential reuse or disposal. This methodical approach minimizes waste and prepares the area for new installation.

Safety and efficiency are paramount during this phase. Wear protective gear, including gloves and safety goggles, to guard against splinters and debris. Work with a partner when handling heavy posts or sections to prevent injury. Dispose of old wood responsibly, either by recycling or arranging for bulk waste pickup. By meticulously inspecting, loosening, and dismantling the old fence, you create a clear, organized workspace and lay the foundation for a successful fence replacement project.

Roy Wood Jr.'s Age: Unveiling the Comedian's Surprising Birth Year

You may want to see also

Explore related products

Prepare New Wood Planks: Measure, cut, and sand planks to fit; ensure smooth edges and proper alignment

Before replacing any section of your two-year-old unstained wood fence, the success of the project hinges on how well you prepare the new wood planks. Precision in measurement, cutting, and sanding not only ensures a seamless fit but also prolongs the life of the fence by preventing gaps where moisture can accumulate. Start by assessing the dimensions of the existing fence panels or sections you’re replacing, using a tape measure to record lengths and widths accurately. Account for any irregularities in the ground level or fence line, as these will dictate custom cuts for a flush fit.

Once measurements are finalized, cutting the planks to size requires the right tools and technique. A circular saw or miter saw is ideal for straight, clean cuts, but a hand saw can suffice for smaller tasks. Always mark your cut lines with a pencil and use a straightedge to guide the saw for accuracy. When cutting, prioritize safety by securing the wood firmly and wearing protective gear, including gloves and safety glasses. Remember, it’s easier to trim a plank slightly larger and refine the fit later than to correct an overly short piece.

Sanding is where the transformation from raw wood to a professional-grade fence component occurs. Begin with medium-grit sandpaper (80–120 grit) to remove rough edges, splinters, and saw marks, then progress to fine-grit (150–220 grit) for a smooth finish. Pay special attention to the ends and edges, as these are prone to splintering and will be most visible once installed. For efficiency, use a power sander for larger surfaces, but switch to hand sanding for corners and detailed areas. A smooth surface not only enhances appearance but also improves stain or sealant adhesion, crucial for unstained wood exposed to the elements.

Alignment is the final, often overlooked step in plank preparation. Dry-fit the planks alongside the existing fence to ensure they match the height, width, and spacing of the original design. Use a level to check vertical alignment and adjust cuts as needed. If replacing multiple planks, maintain consistent spacing between boards for airflow and aesthetic uniformity. This step is your last chance to correct any discrepancies before installation, saving time and effort later.

By meticulously measuring, cutting, sanding, and aligning your new wood planks, you set the foundation for a durable and visually cohesive fence repair. This preparatory work may seem tedious, but it’s an investment in the longevity and functionality of your fence. Properly prepared planks not only fit seamlessly but also resist warping, splitting, and decay, ensuring your two-year-old fence looks and performs like new for years to come.

Chris Wood's Age in The Vampire Diaries: Unveiling the Actor's Timeline

You may want to see also

Explore related products

Install New Fence Sections: Secure posts, attach planks with nails, and ensure stability and straightness

Replacing damaged or worn fence sections is a straightforward task that can significantly enhance the appearance and functionality of your fence. Begin by assessing the existing posts for stability and straightness, as these will serve as the foundation for the new sections. If a post is rotten, leaning, or unstable, it must be replaced before proceeding. Use a post-hole digger to remove the old post and set a new one in concrete, ensuring it is plumb and aligned with the rest of the fence line. Allow the concrete to cure for at least 24 hours before attaching planks.

Attaching the planks requires precision and care to ensure a professional finish. Start by measuring and cutting the planks to fit the desired height and length of the section. Use galvanized nails to prevent rust and corrosion, driving them through the planks and into the posts at a slight angle for added strength. Space the nails evenly, approximately every 12 to 16 inches, to distribute the load and maintain structural integrity. For added durability, consider using screws instead of nails, especially in areas prone to high winds or heavy use.

Stability and straightness are critical to the fence’s longevity and aesthetic appeal. Use a level to check each plank as you attach it, ensuring it is perfectly horizontal or vertical, depending on your design. For long spans, install a support rail midway between the posts to prevent sagging. Reinforce corners and gates with additional bracing, as these areas bear more stress. Periodically step back to inspect the fence line from a distance, making adjustments as needed to maintain a straight and uniform appearance.

A practical tip for ensuring stability is to backfill the post holes with a mixture of gravel and soil before pouring concrete. This provides better drainage and reduces the risk of water pooling around the posts, which can lead to rot. Additionally, pre-drilling holes for nails or screws can prevent the wood from splitting, particularly when working with hardwoods. By combining these techniques, you’ll create a fence section that is not only secure but also visually appealing and built to withstand the test of time.

Elle Woods' Age When She Conquered Harvard Law School

You may want to see also

Explore related products

$115.92

Seal & Protect the Fence: Apply wood sealant or stain to prevent weathering and extend fence life

Wood, left untreated, is vulnerable to the elements. Sun, rain, snow, and temperature fluctuations can cause it to warp, crack, and gray over time. Applying a wood sealant or stain is like giving your fence a protective shield, guarding it against these environmental aggressors. Think of it as sunscreen for your fence, preventing UV damage and moisture penetration that lead to rot and decay.

A two-year-old unstained fence is already at risk. The wood's natural oils have begun to dissipate, leaving it susceptible to damage. Sealants and stains act as a barrier, repelling water and blocking UV rays. This significantly slows down the aging process, keeping your fence looking newer for longer.

Choosing the right product is crucial. Water-based sealants are environmentally friendly and dry quickly, while oil-based options penetrate deeper, offering superior protection but requiring longer drying times. Stains add a touch of color while protecting the wood. Consider the desired aesthetic and the level of protection needed for your climate.

For optimal results, prepare the fence surface thoroughly. Clean it with a mild detergent and water solution, removing dirt, debris, and any mildew. Sand rough patches to ensure a smooth application. Apply the sealant or stain with a brush, roller, or sprayer, following the manufacturer's instructions for coverage and drying times. Typically, two coats are recommended for maximum protection.

Don't underestimate the power of this simple step. Sealing or staining your fence is an investment in its longevity. It's a proactive measure that saves you time and money in the long run by preventing costly repairs or premature replacement. With proper care, your once-vulnerable fence can stand strong and beautiful for years to come.

Stuart Wood's Age: Unveiling the Bay City Rollers Star's Timeline

You may want to see also

Frequently asked questions

You’ll need a hammer, pry bar, screwdriver, drill, new wood boards or panels, galvanized nails or screws, a saw, measuring tape, safety gear (gloves and goggles), and a level. If replacing posts, you may also need concrete mix and a post-hole digger.

Use a pry bar or hammer to carefully remove the nails or screws holding the boards. Work slowly and gently to avoid splitting the wood or damaging the posts. If nails are stuck, use a drill or nail puller to extract them.

It’s best to treat or stain the new wood before installation to ensure even coverage and protection. Use a weather-resistant sealant or stain to prolong the life of the fence and protect it from moisture, UV rays, and pests. Allow the wood to dry completely before attaching it to the posts.