Hauling long pieces of wood in a truck requires careful planning and execution to ensure safety, compliance with transportation laws, and the protection of both the cargo and the vehicle. Properly securing the wood is essential to prevent shifting during transit, which could lead to accidents or damage. Key considerations include using the right equipment, such as ratchet straps, rope, or specialized lumber racks, and ensuring the wood is evenly distributed to avoid overloading any single area of the truck bed. Additionally, understanding local regulations regarding overhanging loads and using flags or lights for visibility can help avoid legal issues and enhance safety on the road. By following these guidelines, you can transport long wood efficiently and securely.

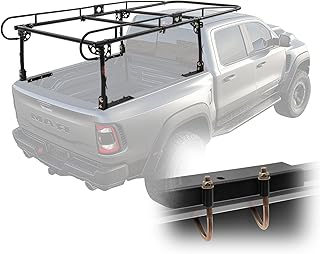

Explore related products

$254.99 $287.99

What You'll Learn

- Secure Loading Techniques: Use proper tie-downs, ratchet straps, and padding to prevent shifting during transit

- Truck Bed Preparation: Add bed extenders or use a trailer hitch for extra length support

- Legal Requirements: Check local laws for wood length limits and flagging overhanging loads

- Weight Distribution: Balance wood evenly to avoid overloading one side of the truck

- Safety Tips: Ensure wood is secure, visible, and does not obstruct driver’s view

Secure Loading Techniques: Use proper tie-downs, ratchet straps, and padding to prevent shifting during transit

Securing long wood in a truck isn’t just about tying it down—it’s about ensuring stability, safety, and compliance with transportation laws. Proper tie-downs, ratchet straps, and padding are the backbone of this process, working together to prevent shifting, damage, and potential hazards on the road. Without these elements, even the most carefully loaded wood can become a liability, risking both your cargo and other drivers.

Step-by-Step Application: Begin by placing the wood lengthwise in the truck bed, ensuring it doesn’t extend more than 4 feet beyond the rear bumper (check local laws for exact limits). Use a minimum of two heavy-duty ratchet straps, one near the front of the truck bed and one near the rear, crisscrossing them for added stability. Tighten the straps until the wood feels immobile but avoid over-tightening, which can damage the wood or truck. Add padding, such as old blankets or foam, between the straps and wood to prevent scratches or dents. For extra security, use a cargo net or additional straps across the top of the load.

Material Matters: Not all tie-downs are created equal. Opt for ratchet straps with a working load limit (WLL) of at least 1,000 pounds, as they provide superior tension control compared to cam buckle straps. Avoid using rope, which can stretch and loosen during transit. For padding, choose materials that won’t shift or compress easily—thick rubber mats or moving blankets are ideal. Inspect all equipment for wear and tear before each use, replacing frayed straps or damaged padding immediately.

Common Mistakes to Avoid: A frequent error is securing the wood only at the ends, leaving the middle section free to shift. Always distribute tension evenly along the length of the load. Another mistake is neglecting to account for wind resistance, which can cause long wood to lift or sway. Use additional straps or a cargo bar to anchor the wood against the truck’s sides. Finally, never rely on the tailgate alone to hold the wood in place—it’s not designed for this purpose and can fail under pressure.

Real-World Takeaway: Properly securing long wood isn’t just about following steps—it’s about understanding the physics of motion. Every bump, turn, and stop transfers energy to your load, and without adequate restraint, that energy can lead to disaster. By investing in quality materials and taking the time to secure your load correctly, you’re not just protecting your cargo—you’re safeguarding lives on the road. Treat this process as non-negotiable, and you’ll haul with confidence every time.

Wood Acclimation: Optimal Time for Post-Production Adjustment and Stability

You may want to see also

Explore related products

$104.49 $109.99

Truck Bed Preparation: Add bed extenders or use a trailer hitch for extra length support

Hauling long wood in a truck often requires more length than the standard bed provides. This is where truck bed extenders and trailer hitches come into play, offering practical solutions to extend your hauling capacity. Bed extenders attach to the tailgate, effectively lengthening the bed by up to 2-3 feet, depending on the model. Trailer hitches, on the other hand, allow you to securely attach a portion of the load to the rear of the truck, distributing weight and reducing the risk of overhang. Both methods are cost-effective compared to renting a larger vehicle or trailer, making them ideal for occasional or DIY hauls.

When choosing a bed extender, consider the material and compatibility with your truck. Aluminum extenders are lightweight and rust-resistant, while steel options offer greater durability but add more weight. Ensure the extender fits your truck’s make and model, and check weight limits—most support 500 to 1,000 pounds. Installation is straightforward: remove the tailgate, slide the extender into place, and secure it with pins or bolts. For trailer hitches, opt for a Class III or IV receiver hitch rated for at least 5,000 pounds, as this will handle the additional load safely. Always verify your truck’s towing capacity in the owner’s manual to avoid overloading.

Using a trailer hitch for long wood requires careful planning. Attach a hitch-mounted cargo carrier or cradle to the receiver, ensuring it’s level and securely fastened. Place the wood so that no more than 4 feet extends beyond the carrier, and use ratchet straps to secure it to the carrier and truck bed. This method is particularly useful for loads that exceed the bed length by 6-8 feet. However, be mindful of local laws regarding overhang—most states allow up to 4 feet beyond the rear bumper without additional flags or lights, but longer loads may require permits or escorts.

Comparing the two methods, bed extenders are simpler to install and remove, making them ideal for shorter loads or frequent use. Trailer hitches, while more complex, offer greater flexibility for longer or heavier loads. For example, a bed extender might suffice for 12-foot lumber, but a 16-foot beam would benefit from the added support of a hitch-mounted carrier. Both methods require proper tie-downs—use ratchet straps with a working load limit (WLL) of at least 1,000 pounds and secure the load at multiple points to prevent shifting during transit.

In conclusion, preparing your truck bed with extenders or a trailer hitch is a practical way to haul long wood safely and efficiently. Assess your load size, frequency of use, and truck specifications to choose the best method. Always prioritize safety by checking weight limits, securing the load properly, and adhering to local regulations. With the right preparation, you can transform your standard truck into a versatile hauling machine capable of handling even the longest lumber with ease.

Understanding Wood Rot: Factors Influencing Decay Development Timeline

You may want to see also

Explore related products

Legal Requirements: Check local laws for wood length limits and flagging overhanging loads

Before loading that lumber, remember: ignorance of the law is no excuse. Every state and even some municipalities have specific regulations regarding the length of wood you can legally transport on public roads. Exceeding these limits can result in hefty fines and endanger other drivers. For instance, in California, any load extending more than four feet beyond the rear of a vehicle must be marked with a red flag during daylight hours and a red light at night.

Let’s break it down into actionable steps. First, consult your state’s Department of Transportation (DOT) website or contact local law enforcement to confirm the maximum allowable overhang. Common limits range from 3 to 5 feet beyond the truck bed, but exceptions may apply for commercial vehicles or specific routes. Second, measure your wood carefully. If it exceeds the limit, consider cutting it to size or securing it diagonally within the truck bed to minimize overhang.

Flagging is not just a suggestion—it’s a legal requirement in most jurisdictions. Use a 12-inch square red flag or a red light visible from 500 feet away for nighttime travel. Attach the flag securely to the end of the load, ensuring it doesn’t obstruct visibility or flutter excessively. For nighttime hauling, a red light must be steady, not flashing, to comply with safety standards.

Comparing states highlights the importance of local research. In Texas, for example, loads overhanging more than four feet must be flagged and accompanied by a "Long Load" sign. In contrast, New York requires flagging for any load extending beyond the truck bed, regardless of length. Such variations underscore why a quick online search or phone call can save you from legal trouble.

Finally, consider the practicalities. Flags and lights are inexpensive and widely available at hardware or auto supply stores. Keep them in your truck as part of your hauling kit, alongside tie-down straps and a measuring tape. Remember, compliance isn’t just about avoiding fines—it’s about ensuring your load doesn’t become a hazard to others. Safe hauling starts with knowing and following the rules.

Installing Wood on Stairs: Timeframe and Tips for a Smooth Process

You may want to see also

Explore related products

Weight Distribution: Balance wood evenly to avoid overloading one side of the truck

Improper weight distribution in a truck bed can lead to dangerous handling, accelerated tire wear, and even structural damage to the vehicle. When hauling long wood, the risk of overloading one side is particularly high due to the material’s length and tendency to shift during transit. A single 2x4 board, for instance, can weigh up to 2 pounds per linear foot, meaning a 16-foot plank weighs approximately 32 pounds. Multiply that by a full load, and the imbalance becomes a significant safety hazard.

To achieve even weight distribution, start by measuring the length of your wood and the width of your truck bed. For example, if hauling 12-foot boards in a 6-foot-wide bed, place half the load on the driver’s side and half on the passenger’s side, ensuring no single section bears more than the truck’s recommended payload capacity (typically 1,000 to 3,000 pounds for light-duty trucks). Use a tape measure to verify alignment, aiming for a 50/50 split along the longitudinal axis.

A common mistake is stacking wood haphazardly, assuming its uniform appearance equates to uniform weight. However, moisture content, density, and species variations can create hidden disparities. For instance, green oak is 30-50% heavier than kiln-dried pine. To mitigate this, alternate boards from different bundles or stacks, and visually inspect for thicker or denser pieces, distributing them across the bed to balance the load.

Securing the wood is equally critical to maintaining balance. Use ratchet straps or cargo nets to anchor the load at multiple points, ensuring tension is applied evenly. For example, crisscross straps over the wood in an "X" pattern to distribute pressure across the entire surface. Avoid relying solely on tailgate restraints, as sudden stops or turns can cause the wood to shift, exacerbating imbalance. Regularly check straps during transit, especially after the first 10 miles, to ensure they haven’t loosened.

Finally, consider the truck’s center of gravity. Overloading the rear can reduce traction on the front wheels, impairing steering and braking. If hauling exceptionally long or heavy wood, place some pieces inside the cab (if possible) or use a trailer to redistribute weight. For trucks with extended cabs, sliding the load slightly forward of the rear axle can improve stability without compromising safety. Always refer to your vehicle’s manual for specific weight limits and loading guidelines.

Cedar Wood Chips Decomposition: Breakdown Timeline and Factors Explained

You may want to see also

Explore related products

$549.99 $599.99

$106.9

Safety Tips: Ensure wood is secure, visible, and does not obstruct driver’s view

Securing long wood in a truck isn’t just about tying it down—it’s about ensuring it stays put, no matter the road conditions. Use heavy-duty ratchet straps or rope rated for the weight of your load, and anchor them to the truck’s tie-down points, not the bed rails. Cross-tie the wood in an "X" pattern to distribute tension evenly, and ensure each piece is snug against the truck bed to prevent shifting. A single loose board can become a projectile, so double-check every strap before hitting the road.

Visibility is as critical as security. Long wood extending beyond the truck bed must be marked with a red flag or reflective tape on the end to alert other drivers, especially during low-light conditions. Federal regulations require any load extending more than 4 feet beyond the rear to have a red flag at least 12 inches square or two red lights at night. Failure to comply not only risks accidents but also hefty fines. Treat these markings as non-negotiable, regardless of how short your trip might be.

A common mistake is overlooking how the load affects the driver’s view. Never stack wood so high that it blocks the rearview or side mirrors—this defeats the purpose of hauling safely. If visibility is compromised, reposition the load or use a spotter for backing up. For taller loads, consider using a cab-high rack or securing the wood flat against the bed to maintain a clear line of sight. Remember, if you can’t see properly, neither can the drivers around you.

Comparing methods, a lumber rack is an investment that pays off in safety and convenience. It keeps wood elevated, reducing the risk of obstruction and making it easier to secure. However, if using the truck bed alone, angle the wood slightly toward the cab to prevent it from sliding forward. Pair this with a cargo net for added stability, especially on bumpy roads. The goal is to create a load that behaves predictably, no matter how hard you brake or turn.

Finally, inspect your setup at every stop. Straps can loosen, and wood can shift, even with the best initial securing. Carry extra tie-downs and a utility knife to adjust or cut straps if needed. Think of hauling wood like a dynamic system—it requires constant monitoring, not just a one-time setup. By treating safety as an ongoing process, you protect not only your cargo but everyone sharing the road.

Gorilla Wood Filler Drying Time: Quick Guide for Perfect Repairs

You may want to see also

Frequently asked questions

Secure the wood diagonally across the truck bed, ensuring it rests against the cab and extends slightly beyond the tailgate. Use ratchet straps or ropes to tie it down at multiple points, and add a red flag or reflective tape to the end for visibility.

Yes, but ensure no more than 4 feet extends beyond the tailgate. Use a proper tie-down system, and check local laws for specific regulations on overhang and safety requirements.

Use non-slip pads or carpet remnants between the wood and truck bed to prevent sliding. Tighten straps securely, and avoid overloading the truck to maintain stability. Regularly check the load during stops.