Making long wood clamps is an essential skill for woodworkers looking to securely hold large or lengthy workpieces during gluing, assembly, or finishing. These clamps can be crafted using readily available materials such as wood, metal pipes, or threaded rods, combined with simple hardware like nuts, washers, and wooden jaws. The process involves cutting and shaping the wooden jaws to fit the project’s needs, attaching them to a sturdy backing board or beam, and incorporating a mechanism for applying pressure, such as a threaded rod or pipe with handles. By customizing the length and design, woodworkers can create clamps tailored to their specific projects, ensuring even pressure distribution and minimizing the risk of warping or misalignment. This DIY approach not only saves costs but also allows for greater flexibility in tackling a variety of woodworking tasks.

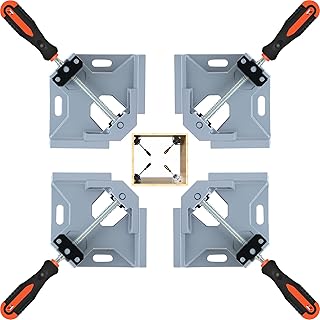

Explore related products

What You'll Learn

- Materials Needed: Essential tools and materials for constructing durable, long wood clamps effectively

- Design Considerations: Key factors for designing clamps to fit various woodworking project sizes

- Assembly Steps: Detailed process for assembling clamp components securely and accurately

- Adjustability Features: Adding mechanisms to ensure clamps adapt to different wood thicknesses

- Finishing Techniques: Tips for sanding, sealing, and enhancing clamp durability and appearance

Materials Needed: Essential tools and materials for constructing durable, long wood clamps effectively

Woodworking enthusiasts often turn to long clamps for projects requiring extended reach and consistent pressure. To construct durable, long wood clamps effectively, start with high-quality materials that balance strength, flexibility, and longevity. The backbone of your clamp will be hardwood for the jaws and handles, such as maple or oak, which offer excellent durability and resistance to warping under pressure. For the threaded rod, opt for a ½-inch or ⅝-inch steel rod, ensuring it’s zinc-coated to prevent rust and maintain smooth operation. Pair this with a sturdy nut and handle mechanism, like a T-handle or wingnut, for easy adjustments.

Next, consider the glue and fasteners. Epoxy resin or polyurethane glue provides a strong bond for joining wooden components, especially in areas subjected to stress, like the jaw-handle connection. Use stainless steel screws or bolts for assembling parts, as they resist corrosion and ensure longevity. For added stability, incorporate a rubber pad or non-slip material on the clamp faces to protect the workpiece and enhance grip. These materials, when chosen thoughtfully, form the foundation of a clamp that performs reliably under pressure.

While the core materials are essential, don’t overlook the importance of precision tools for construction. A drill press ensures accurate holes for the threaded rod, while a table saw or bandsaw allows for clean, straight cuts in the wood. Sandpaper in varying grits (80 to 220) smooths surfaces and prepares them for glue or finish. If you’re adding a finish for aesthetics or protection, consider tung oil or polyurethane, which provide durability without compromising the wood’s natural look. Each tool and material plays a specific role, contributing to the clamp’s overall effectiveness and lifespan.

Finally, think about scalability and customization. If you plan to build clamps of varying lengths, invest in longer threaded rods and additional wooden stock. For specialized projects, consider adding features like swivel pads or quick-release mechanisms, which require additional materials like ball bearings or spring-loaded components. By selecting materials with both immediate needs and future projects in mind, you ensure your clamps remain versatile and durable across a range of woodworking tasks. This foresight transforms a simple tool into a long-lasting asset in your workshop.

Mayonnaise on Wood: Surprising Benefits and Ideal Application Time

You may want to see also

Explore related products

Design Considerations: Key factors for designing clamps to fit various woodworking project sizes

Designing clamps for diverse woodworking projects demands a nuanced understanding of material compatibility. Hardwoods like oak or maple require robust clamps with non-marring pads to prevent surface damage, while softer woods such as pine may tolerate simpler designs. For metal or composite materials, consider corrosion-resistant metals like stainless steel or aluminum to ensure longevity. Always match the clamp’s jaw material to the project’s surface finish to avoid scratches or discoloration.

Adjustability is non-negotiable when crafting clamps for varied project sizes. Incorporate threaded rods or sliding mechanisms that allow for precise tension control, accommodating widths from 6 inches to over 4 feet. For longer clamps, use telescoping designs with locking pins to maintain stability without adding excessive weight. Test the range of motion during prototyping to ensure smooth adjustments under load, avoiding binding or slippage that could compromise clamping force.

Ergonomics play a critical role in clamp design, especially for extended use. Handles should be contoured to fit the hand comfortably, with a grip diameter between 1.5 and 2 inches for optimal torque application. Position the handle at a 30-degree angle to the clamp body to reduce wrist strain during tightening. For larger clamps, consider adding a secondary handle or foot pedal mechanism to distribute effort and prevent fatigue during prolonged clamping tasks.

Durability hinges on the choice of fasteners and joinery techniques. Use hardened steel screws or bolts with locking nuts to secure moving parts, minimizing play over time. For wooden components, opt for dovetail or mortise-and-tenon joints reinforced with waterproof glue to withstand humidity fluctuations. Regularly inspect stress points, such as pivot points and jaw hinges, and incorporate wear plates or bushings to extend the clamp’s service life.

Finally, portability and storage must inform the design of long clamps. Modular designs that disassemble into compact components are ideal for workshops with limited space. Include integrated hanging hooks or nesting features to streamline organization. For on-site use, prioritize lightweight materials like hollow aluminum or composite polymers, ensuring the clamp remains functional without becoming cumbersome during transport. Balance strength with practicality to create a tool that adapts seamlessly to any woodworking environment.

How Long Does Gorilla Glue Last on Wood Surfaces?

You may want to see also

Explore related products

Assembly Steps: Detailed process for assembling clamp components securely and accurately

The assembly of long wood clamps demands precision and attention to detail to ensure both functionality and durability. Begin by laying out all components—rails, jaws, screws, and handles—on a clean, flat surface. Verify each piece aligns with your design specifications, as even minor discrepancies can compromise performance. Use a square to confirm perpendicularity between the jaws and rails, a critical step for even clamping pressure.

Next, attach the jaws to the rails using countersunk screws to maintain a flush surface. Pre-drill holes to prevent wood splitting, especially in hardwoods. Apply a small amount of wood glue to the mating surfaces for added strength, but avoid over-application to prevent squeeze-out. Tighten screws incrementally, alternating sides to ensure even distribution of force. This method minimizes warping and guarantees a secure bond.

Once the jaws are secured, install the screw mechanism. Thread the screw through the rail, ensuring smooth rotation without binding. Use a washer between the screw and rail to reduce friction and extend the clamp’s lifespan. Test the screw’s movement by turning the handle; it should engage the jaw smoothly without resistance. If binding occurs, disassemble and sand the contact points until operation is seamless.

Finally, attach the handle to the screw, ensuring it’s firmly seated and allows for comfortable operation. Consider adding a rubber grip for enhanced control, especially during prolonged use. Test the clamp by applying pressure to a scrap piece of wood, checking for slippage or misalignment. Adjust as needed, tightening any loose components before final use. This meticulous assembly process ensures your long wood clamp performs reliably under pressure.

Mastering Wood Glue Clamping: Optimal Time for Strong, Durable Joints

You may want to see also

Explore related products

Adjustability Features: Adding mechanisms to ensure clamps adapt to different wood thicknesses

One of the most critical aspects of long wood clamps is their ability to accommodate various wood thicknesses without compromising pressure or stability. Achieving this requires thoughtful integration of adjustability mechanisms. A common approach is incorporating sliding or telescoping components that allow the clamp’s jaws to extend or retract along a rail system. For instance, a T-track embedded in the clamp’s backbone paired with movable carriages ensures precise positioning. This design not only adapts to different thicknesses but also maintains even pressure across the entire surface, reducing the risk of warping or damage.

Another effective method is the use of threaded rods or screws with oversized handles for fine-tuning. By turning the handle, the clamp’s jaw moves incrementally, allowing for micro-adjustments that cater to both thin veneers and thick lumber. This mechanism is particularly useful when working with projects requiring exact alignment, such as cabinetmaking or furniture assembly. However, it’s essential to balance precision with ease of use; overly complex systems can slow down workflow, while too simple designs may lack the necessary granularity.

For those seeking a more dynamic solution, spring-loaded or ratcheting mechanisms offer automatic adjustability. These clamps detect the thickness of the wood and self-adjust to apply consistent pressure. While convenient, they often come with limitations in maximum capacity and may not suit heavy-duty applications. Additionally, their reliance on internal springs can lead to wear over time, requiring periodic maintenance or replacement.

When designing adjustable clamps, material selection plays a pivotal role. Aluminum or steel rails provide durability and smooth movement, while plastic or rubberized jaw pads prevent marring the wood surface. Incorporating quick-release levers or cam locks can further enhance usability, allowing for rapid adjustments without sacrificing clamping force. Always test prototypes with a range of wood thicknesses to ensure the mechanism functions reliably under varying conditions.

In conclusion, the key to successful adjustability lies in balancing precision, durability, and user-friendliness. Whether through sliding tracks, threaded rods, or automated systems, the goal is to create a clamp that adapts seamlessly to the task at hand. By carefully considering the mechanism’s design and materials, woodworkers can craft long clamps that are both versatile and efficient, elevating the quality and efficiency of their projects.

Burnt Wood Durability: Does Charred Timber Outlast Untreated Wood?

You may want to see also

Explore related products

$11.99 $12.99

$14.99 $18.74

Finishing Techniques: Tips for sanding, sealing, and enhancing clamp durability and appearance

Sanding is the foundation of a flawless finish, especially for wood clamps where smooth surfaces ensure even pressure distribution. Begin with a medium-grit sandpaper, such as 120-grit, to remove any rough edges or imperfections. Progress to finer grits (220-grit, then 320-grit) to achieve a satin-smooth texture. Pay special attention to areas where the clamp will contact the wood, as these surfaces directly impact performance. For intricate or hard-to-reach areas, consider using sanding sponges or folded sandpaper for precision. Always sand in the direction of the wood grain to avoid scratches that could mar the final appearance.

Sealing the wood is crucial for both durability and aesthetics. A quality wood sealant, such as polyurethane or Danish oil, protects the clamp from moisture, stains, and wear. Apply the sealant in thin, even coats using a brush or cloth, allowing each layer to dry completely before adding the next. For clamps intended for heavy use, consider a marine-grade varnish for added resilience. If you prefer a natural look, opt for a clear matte finish; for a richer tone, choose a tinted sealant. Ensure proper ventilation during application, and lightly sand between coats with 400-grit paper to achieve a smooth, professional finish.

Enhancing the appearance of your wood clamps can elevate them from functional tools to works of craftsmanship. Consider adding a decorative touch, such as a wood-burning design or a coat of stain to highlight the grain. For a modern aesthetic, experiment with contrasting colors or geometric patterns. If the clamp has metal components, polish them to a high sheen for a striking visual contrast. Remember, the goal is to balance form and function—ensure any decorative elements do not interfere with the clamp’s performance. A well-finished clamp not only looks impressive but also reflects the care and skill invested in its creation.

To maximize durability, focus on both the wood and any hardware components. Treat metal parts with a rust-inhibiting primer and finish with a durable paint or powder coating. For wooden components, consider reinforcing stress points with epoxy or wood hardeners. If the clamp will be exposed to outdoor conditions, incorporate UV-resistant sealants to prevent fading and cracking. Regular maintenance, such as periodic re-sealing and inspection for wear, will extend the clamp’s lifespan. By combining thoughtful finishing techniques with proactive care, your long wood clamps will remain both functional and visually appealing for years to come.

Basement Wood Swelling: Duration and Effective Remedies Explained

You may want to see also

Frequently asked questions

You will need wood (such as 2x4s or hardwood), threaded rods or bolts, nuts, washers, and wood glue. Optionally, you can add handles or grips for easier use.

Measure the length of the project you’re clamping and add a few inches to ensure the clamp can fully secure the workpiece. Standard lengths range from 24 to 48 inches.

Drill holes through the wood pieces, insert the threaded rod, and secure it with nuts and washers on both ends. Ensure the rod is centered and the wood pieces are aligned.

Yes, attach a layer of soft material like leather, rubber, or foam to the clamp faces using adhesive or screws to prevent marring the wood surface.

![Right Angle Clamp, Housolution [4 PACK] Single Handle 90° Aluminum Alloy Corner Clamp, Clamps for Woodworking Adjustable Swing Jaw, Woodworking Tools Photo Frame Vise Holder, Gifts for Men Dad](https://m.media-amazon.com/images/I/71xNSiBOZ+L._AC_UL320_.jpg)