Restoring old wooden floorboards can breathe new life into a space, preserving its character and charm while enhancing its durability. The process begins with a thorough assessment of the floor’s condition, identifying issues like scratches, stains, warping, or gaps between boards. Next, cleaning the surface to remove dirt, grime, and old finishes is essential, often using a gentle wood cleaner or sanding for more stubborn residue. Sanding the floorboards is a critical step, as it smooths out imperfections and prepares the wood for refinishing; this can be done by hand or with a floor sander, depending on the area’s size and the damage’s extent. Once sanded, any gaps or cracks should be filled with wood filler or slivers of matching wood for a seamless look. Staining can then be applied to achieve the desired color, followed by sealing with a protective finish like polyurethane to guard against wear and tear. Finally, allowing ample drying time ensures a professional, long-lasting result that showcases the natural beauty of the restored wood.

| Characteristics | Values |

|---|---|

| Preparation | Clear the room, remove carpets, and inspect for damage or loose boards. |

| Cleaning | Sweep, vacuum, and mop with a mild wood cleaner to remove dirt and grime. |

| Sanding | Use a drum sander (coarse to fine grit) to remove old finish and smoothen. |

| Repairs | Fill gaps with wood filler or slivers, replace damaged boards if necessary. |

| Staining (Optional) | Apply wood stain evenly for desired color, allow to dry completely. |

| Sealing | Use polyurethane, varnish, or oil-based sealant for protection and shine. |

| Buffing and Polishing | Buff the surface after sealing for a smooth finish, then polish if needed. |

| Maintenance | Regularly sweep, avoid harsh chemicals, and reapply sealant every 5-10 yrs. |

| Tools Required | Drum sander, orbital sander, wood filler, stain, sealant, brushes, cloths. |

| Time Frame | 2-5 days depending on room size and condition of floorboards. |

| Cost | $1-$5 per square foot (DIY), $3-$8 per square foot (professional). |

| Safety Precautions | Wear masks, goggles, and ear protection during sanding; ensure ventilation. |

| Environmental Impact | Use eco-friendly products to minimize chemical waste and fumes. |

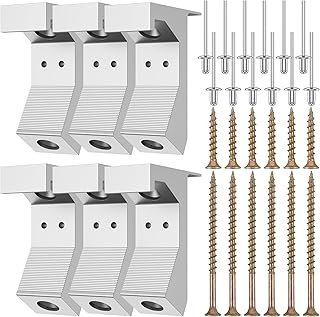

Explore related products

What You'll Learn

- Preparation: Clear room, remove carpet, and inspect floorboards for damage or nails

- Cleaning: Sweep, vacuum, and scrub floorboards to remove dirt, grime, and old finish

- Repairs: Replace broken boards, fill gaps with wood filler, and secure loose planks

- Sanding: Use drum or belt sander to smooth surface, followed by edge sanding

- Finishing: Apply stain (optional), seal with polyurethane, and buff for a polished look

Preparation: Clear room, remove carpet, and inspect floorboards for damage or nails

Before you can breathe new life into old wooden floorboards, you need to see what you're working with. Start by clearing the room entirely. Remove all furniture, rugs, and decor to create an unobstructed workspace. This step is crucial not only for access but also to prevent damage to your belongings during the restoration process. Once the room is empty, tackle the carpet. Use a utility knife to cut it into manageable strips, rolling it up as you go. Don’t forget to remove the underlay and any adhesive residue left behind. Tack strips, those wooden strips with nails along the edges, should be pried up carefully with a crowbar to avoid damaging the floorboards.

With the carpet gone, the floorboards are finally exposed, revealing their true condition. This is the moment of truth. Inspect every inch of the floor for damage, such as cracks, warping, or rot. Pay special attention to areas near windows, doors, and radiators, where moisture damage is more likely. Loose or protruding nails are another common issue—use a nail punch to sink them below the surface or remove them entirely if they’re too damaged. For stubborn nails, a pair of pliers can be your best friend. Document any significant damage with photos or notes; this will help you plan repairs and estimate costs.

The inspection phase is also your chance to assess the floor’s overall character. Look for signs of wear that add charm, like patina or subtle color variations, and distinguish them from damage that needs fixing. For instance, minor scratches or dents might be left as-is to preserve the floor’s history, while deep gouges or splintered boards will likely require replacement. If you’re unsure about the extent of the damage, consult a professional to avoid costly mistakes. Remember, the goal is to restore, not replace, so prioritize preserving the floor’s original integrity.

Finally, cleanliness is key before moving forward. Sweep the floor thoroughly to remove debris, then vacuum to catch any lingering dust or particles. For stubborn adhesive residue, use a scraper or a chemical adhesive remover, but test it on a small area first to ensure it doesn’t harm the wood. Once clean, the floor is ready for the next steps—sanding, staining, or sealing. Proper preparation ensures that your restoration efforts will be effective and long-lasting, transforming worn floorboards into a stunning centerpiece of your home.

Revitalize Your Old Wood Cabinets: Easy Steps to a Fresh Look

You may want to see also

Explore related products

$14.99 $21.99

Cleaning: Sweep, vacuum, and scrub floorboards to remove dirt, grime, and old finish

The first step in restoring old wooden floorboards is to remove the layers of dirt, grime, and old finish that have accumulated over time. This initial cleaning process is crucial, as it prepares the surface for further restoration work, ensuring that any repairs, sanding, or refinishing adhere properly. Neglecting this step can lead to uneven results, with new finishes failing to bond or old stains seeping through.

Steps to Effective Cleaning:

- Sweep Thoroughly: Begin by sweeping the floorboards with a soft-bristled broom to remove loose dirt, dust, and debris. Pay attention to corners and edges where particles tend to accumulate. For larger areas, a wide dustpan or shop vacuum can expedite the process.

- Vacuum for Precision: Follow sweeping with a vacuum cleaner equipped with a hardwood floor attachment. This ensures the removal of finer particles that sweeping might miss, especially in gaps between boards. Avoid using beater bars, as they can scratch the wood.

- Scrub with Care: Mix a mild cleaning solution—one gallon of warm water with 1/2 cup of white vinegar or a pH-neutral wood cleaner—and apply it sparingly with a microfiber mop or sponge. Scrub gently along the grain to lift stubborn grime and old finish. Avoid oversaturating the wood, as excessive moisture can cause warping or discoloration.

Cautions and Practical Tips:

- Test the cleaning solution on a small, inconspicuous area first to ensure it doesn’t damage the wood.

- For heavily soiled floors, use a stiff-bristled brush, but apply minimal pressure to avoid gouging the surface.

- Work in sections, cleaning and drying one area before moving to the next to prevent water from pooling.

Comparative Insight: While power washing might seem efficient, it’s unsuitable for wooden floorboards due to the risk of water damage. Similarly, harsh chemicals like bleach or ammonia can strip the wood’s natural oils, leaving it dry and brittle. Opt for gentle, wood-safe solutions instead.

Eco-Friendly Ways to Dispose of Old Wood Responsibly and Creatively

You may want to see also

Explore related products

Repairs: Replace broken boards, fill gaps with wood filler, and secure loose planks

Broken or damaged floorboards are more than an eyesore; they compromise the structural integrity of your floor. Start by identifying boards that are cracked, warped, or rotten beyond repair. Use a utility knife to score along the damaged board’s edges, then pry it up carefully with a crowbar, ensuring you don’t damage adjacent planks. Measure the gap and cut a replacement board to fit, allowing for a 1/8-inch expansion gap at the ends. Secure the new board with finishing nails, driving them at a slight angle through the tongue side of the board to avoid splitting. For a seamless finish, stain or seal the replacement to match the surrounding floor.

Gaps between floorboards can harbor dust, reduce insulation, and detract from the floor’s appearance. Wood filler is an effective solution, but not all fillers are created equal. Choose a high-quality, flexible wood filler that matches the color of your floorboards. For larger gaps, mix sawdust from the same wood species with wood glue to create a custom filler. Apply the filler with a putty knife, pressing it firmly into the gap. Allow it to dry completely, then sand it flush with the surface. For stubborn gaps that reopen due to seasonal expansion, consider using rope or strips of cork as a base before applying filler to provide flexibility.

Loose planks are a tripping hazard and a sign of weakened subflooring. Begin by inspecting the underside of the floor, if accessible, to identify missing nails or weakened joists. If the subfloor is intact, drive ring-shank flooring nails through the plank at a 45-degree angle, spacing them every 6–8 inches. For added stability, use a pneumatic flooring nailer. If the subfloor is damaged, reinforce it with plywood or sister joists before securing the planks. For floors with a history of movement, adhesive construction glue along the edges of the plank can provide extra hold, though this should be used sparingly to avoid excess mess.

While repairs are essential, they’re only part of the restoration process. Replacing boards, filling gaps, and securing planks address immediate issues but must be followed by sanding, staining, and sealing to ensure longevity. Always test repairs in a small, inconspicuous area first to ensure compatibility with your floor’s age and condition. For historic floors, consult a preservation specialist to avoid irreversible damage. Done correctly, these repairs not only restore functionality but also preserve the character and charm of your old wooden floorboards for years to come.

Master the Art of Aging Wood: Techniques for a Timeless Look

You may want to see also

Explore related products

Sanding: Use drum or belt sander to smooth surface, followed by edge sanding

Sanding is the backbone of floorboard restoration, stripping away decades of wear, stains, and imperfections to reveal the wood’s original character. The process begins with a drum or belt sander, heavy-duty machines designed to tackle large surface areas efficiently. These sanders use coarse-grit sandpaper (typically 40–60 grit) to remove old finishes, scratches, and uneven patches. The key is to move the sander in a consistent, straight-line pattern, avoiding swirls or diagonal strokes that can create visible marks. Always sand with the grain to prevent splintering and ensure a smooth finish.

While drum and belt sanders excel at flattening broad surfaces, they’re too bulky to reach the edges and corners of a room. This is where edge sanding comes in—a critical step often overlooked by amateurs. Use an edge sander or a handheld orbital sander with the same grit as the initial pass to smooth the perimeter. Focus on areas where the larger sander couldn’t reach, such as along baseboards or in tight corners. Skipping this step leaves unsanded edges, creating an uneven finish once the floor is refinished.

A common mistake is rushing the sanding process or using too fine a grit too soon. Start with a coarse grit to remove the bulk of the damage, then progress to medium (80–100 grit) and fine (120–150 grit) grits for a polished surface. Each pass should refine the wood further, but avoid over-sanding, which can thin the boards or create dips. For older, softer woods like pine, exercise caution—they’re more prone to gouging under aggressive sanding.

Practical tips can make this labor-intensive task more manageable. Rent professional-grade sanders from a hardware store rather than buying, as they’re more powerful and efficient than consumer models. Wear a respirator and ear protection, as sanding generates fine dust and loud noise. Work in sections, vacuuming between grit changes to avoid clogging the sandpaper. Finally, test the floor’s smoothness with your hand—any rough spots indicate the need for further sanding.

The takeaway? Sanding isn’t just about removing the old; it’s about preparing the wood for its new life. Done correctly, it ensures a flawless foundation for staining, sealing, or finishing. While time-consuming, the transformation from dull, damaged boards to a smooth, ready-to-refinish surface is well worth the effort. Master this step, and you’ve laid the groundwork for a floor that looks as good as the day it was installed.

Natalie Wood's Age in West Side Story: A Surprising Fact

You may want to see also

Explore related products

Finishing: Apply stain (optional), seal with polyurethane, and buff for a polished look

The final steps in restoring old wooden floorboards are where your hard work truly shines. Finishing not only enhances the wood's natural beauty but also protects it from wear and tear, ensuring longevity. This stage involves three key processes: staining (optional), sealing with polyurethane, and buffing for a polished look. Each step requires attention to detail and the right materials to achieve a professional finish.

Staining: Enhancing Character (Optional)

Staining is a personal choice that allows you to alter the wood’s color while preserving its texture. If your floorboards have aged to a hue you love, skip this step. However, if you desire a richer tone or need to unify mismatched boards, choose a water- or oil-based stain. Water-based stains dry faster and emit fewer fumes, while oil-based options penetrate deeper for a more durable finish. Apply the stain evenly with a brush or rag, following the wood grain. Allow it to dry according to the manufacturer’s instructions—typically 2–4 hours for water-based and 8–12 hours for oil-based stains. Test the color on a small, inconspicuous area first to ensure it meets your expectations.

Sealing with Polyurethane: The Protective Barrier

Polyurethane is the workhorse of floor finishes, providing a durable shield against scratches, moisture, and daily use. Opt for a water-based polyurethane for low odor and quick drying (2–3 hours between coats) or an oil-based version for a warmer amber tone and higher durability (8–12 hours drying time). Apply the first coat with a lambswool applicator or foam pad, working in the direction of the grain. Allow it to dry completely before lightly sanding with 220-grit sandpaper to smooth any raised fibers. Apply 2–3 additional coats, sanding lightly between each, to build a robust finish. Proper ventilation is crucial during this process—use fans and open windows to disperse fumes.

Buffing: The Final Polish

Once the polyurethane has fully cured (48–72 hours), buffing adds a professional, polished sheen. Use a floor buffer with a fine-grit sanding screen or a polishing pad to gently abrade the surface, removing any minor imperfections and creating a uniform finish. Follow this with a microfiber cloth to wipe away dust. For an extra glossy look, apply a floor wax or polish compatible with polyurethane finishes. Buffing not only enhances the aesthetic but also ensures the floor feels smooth underfoot, completing the restoration process with a touch of elegance.

Practical Tips for Success

Maintain a consistent room temperature (60–80°F) during finishing to ensure proper drying and adhesion. Avoid walking on the floor until the final coat has cured fully. For high-traffic areas, consider adding an extra coat of polyurethane for added protection. Finally, invest in quality materials—cheap stains or sealers can lead to uneven finishes or premature wear. With patience and precision, your restored floorboards will not only look timeless but also withstand the test of time.

Is Old Man of the Woods Edible? A Forager's Guide

You may want to see also

Frequently asked questions

Start by clearing the room and removing any carpets or nails. Sweep or vacuum the floor to remove dust and debris. Inspect the boards for damage, such as loose or broken planks, and replace or repair them as needed. Sand the floor lightly to remove surface dirt and old finishes, ensuring the surface is smooth and ready for refinishing.

Essential tools include a floor sander (drum or orbital), sandpaper in various grits (e.g., 40, 80, 120), a nail punch to countersink protruding nails, a pry bar for removing damaged boards, a shop vacuum for dust cleanup, and a paintbrush or roller for applying finishes. Safety gear like masks, goggles, and ear protection is also crucial.

For small gaps, use a wood filler or putty that matches the floor’s color. For larger gaps, consider inserting wooden slivers or strips cut from matching wood. After filling, sand the area smooth to blend it with the surrounding floor. If gaps are due to humidity changes, ensure proper ventilation and consider using a humidifier or dehumidifier to stabilize the environment.

Choose a finish based on durability and appearance. Polyurethane is popular for its hardness and resistance to scratches and stains. Oil-based finishes penetrate the wood for a natural look but require more maintenance. Water-based finishes dry quickly and have low odor but may not be as durable. Apply the finish in thin, even coats, following the manufacturer’s instructions.