When buying wood, the term leaf typically refers to a thin, decorative layer of high-quality wood veneer applied to the surface of a less expensive or lower-grade substrate, such as plywood or particleboard. This technique, known as veneering, allows for the use of premium wood species like walnut, mahogany, or maple in furniture, cabinetry, or flooring without the high cost of solid wood construction. The leaf, or veneer, is carefully sliced or peeled from a log and adhered to the core material, providing the aesthetic appeal of natural wood grain while ensuring durability and stability. Understanding the meaning of leaf in this context helps buyers make informed decisions about the quality, appearance, and value of the wood products they are purchasing.

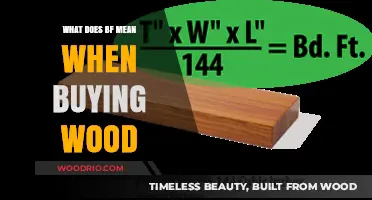

| Characteristics | Values |

|---|---|

| Definition | "Leaf" in woodworking refers to a thin, flat piece of wood, typically used for decorative purposes or as a veneer. |

| Thickness | Usually less than 1/8 inch (3 mm), often much thinner. |

| Application | Commonly used for furniture, cabinetry, and decorative panels. |

| Material | Can be made from various wood species, including hardwoods and softwoods. |

| Veneer Usage | Often used as a veneer to cover less expensive or structurally sound wood. |

| Flexibility | Thin leaves are flexible, allowing them to be bent or curved for specific designs. |

| Grain Pattern | Highlights the natural grain and color of the wood species. |

| Cost | Generally more expensive than solid wood due to the labor-intensive process of slicing or peeling. |

| Durability | Less durable than solid wood; requires careful handling and protection. |

| Sustainability | Can be a sustainable option as it maximizes the use of a single log by creating multiple thin layers. |

| Finishing | Easily accepts stains, paints, and finishes to enhance appearance. |

| Common Uses | Furniture inlays, door panels, and decorative accents. |

Explore related products

What You'll Learn

- Leaf as a Wood Grade: Refers to veneer quality, affecting appearance and value in plywood or furniture

- Leaf Veneer Thickness: Indicates the slice thickness used in wood layering for aesthetics

- Leaf in Wood Types: Specific to certain woods like leaf maple, known for unique grain

- Leaf in Pricing: Higher-grade leaf veneers increase wood product costs significantly

- Leaf Durability: Quality of leaf veneer impacts long-term wear and maintenance needs

Leaf as a Wood Grade: Refers to veneer quality, affecting appearance and value in plywood or furniture

In the world of woodworking and furniture making, the term "leaf" takes on a specific and crucial meaning, particularly when discussing wood grades and veneer quality. When you're in the market for plywood or fine furniture, understanding what "leaf" signifies can be the difference between a wise investment and a costly mistake. This term is not about the foliage of a tree but rather a critical indicator of the wood's surface quality and, by extension, its value.

The Veneer of Quality

"Leaf" in this context refers to the outermost layer of wood, the veneer, which is a thin slice of high-quality wood used to cover a less expensive base. This veneer is what gives a piece of furniture or plywood its visual appeal, mimicking the look of solid wood. The grade of this leaf directly impacts the overall aesthetics and, consequently, the price. A high-grade leaf will have a consistent color, minimal defects, and a smooth, uniform texture, making it highly desirable for premium furniture and decorative panels.

Grading the Leaf: A Closer Look

Wood graders inspect the veneer for various characteristics. These include the presence of knots, mineral streaks, and other natural imperfections. The size, color, and distribution of these features determine the leaf's grade. For instance, a 'clear' grade leaf will have few to no defects, offering a pristine appearance, while a 'common' grade may show more character with larger knots and color variations. Each grade has its market, from high-end furniture to more rustic, natural-looking pieces.

Impact on Value and Application

The leaf grade significantly influences the cost and intended use of the wood product. Premium grades command higher prices due to their superior aesthetics and the skill required to produce them. These are often used in visible areas of furniture, such as tabletops and cabinet doors, where beauty is paramount. Lower grades, while more affordable, are typically used in less conspicuous areas or for structural purposes, where appearance is secondary to functionality.

Practical Considerations for Buyers

When purchasing wood products, especially plywood or veneered furniture, buyers should consider the following:

- Inspect the Leaf: Examine the veneer for consistency and defects. Ensure it meets your aesthetic requirements.

- Understand Grading Systems: Familiarize yourself with the grading standards used by the manufacturer or supplier.

- Balance Cost and Quality: Decide where to allocate your budget based on the visibility and importance of the wood's appearance in your project.

- Ask for Samples: Request samples or view completed pieces to better understand the leaf's quality and how it translates into the final product.

In the realm of woodworking, the term "leaf" is a critical specifier, offering insight into the quality and value of wood products. By understanding this grading system, buyers can make informed decisions, ensuring they get the desired look and value for their money. This knowledge is particularly valuable for those seeking to create or invest in high-quality, visually appealing wooden pieces.

Buying a Kiln for Wood Drying: Is It the Right Choice?

You may want to see also

Explore related products

Leaf Veneer Thickness: Indicates the slice thickness used in wood layering for aesthetics

Wood veneer, often referred to as "leaf" in the industry, is a thin slice of wood used to cover less aesthetically pleasing surfaces. The thickness of this leaf veneer plays a pivotal role in determining the final appearance, durability, and application suitability of the wood product. Typically, veneer thickness ranges from 0.5mm to 6mm, with each increment offering distinct advantages and limitations. For instance, a 0.5mm veneer is ultra-thin and flexible, ideal for curved surfaces or intricate designs, but it requires meticulous handling to avoid tearing. Conversely, a 6mm veneer, often called "thick veneer," provides robustness and is suitable for high-traffic areas like flooring, though it lacks the flexibility needed for complex shapes.

When selecting leaf veneer thickness, consider the intended use and the desired aesthetic. Thinner veneers (0.5mm–1.5mm) are perfect for decorative panels, furniture inlays, or door skins, where their delicate nature enhances visual appeal without compromising structural integrity. However, they are less forgiving during installation and may require professional application. Medium-thickness veneers (2mm–3mm) strike a balance, offering durability for everyday use while remaining versatile enough for most woodworking projects. Thicker veneers (4mm–6mm) are best reserved for applications where strength and longevity are paramount, such as tabletops or wall cladding, but they demand precise cutting and adhesion techniques.

The slicing method used to create the veneer also influences its thickness and grain pattern. Rotary-cut veneers, produced by spinning a log against a blade, yield thicker slices with a more uniform grain, making them cost-effective for large-scale projects. In contrast, flat-cut or rift-cut veneers, which are sliced tangentially or radially along the log, produce thinner, more visually striking patterns but are often more expensive. Understanding these cutting techniques helps buyers align veneer thickness with both budget and design goals.

Practical tips for working with leaf veneer include acclimating the material to the installation environment for 48 hours to prevent warping, using a high-quality adhesive like contact cement or epoxy, and employing a veneer hammer or roller to ensure proper bonding. For thinner veneers, backing them with a substrate like MDF or plywood adds stability and ease of handling. Always test a small sample before committing to a full project, especially when experimenting with unconventional thicknesses or applications.

In summary, leaf veneer thickness is a critical factor in achieving both functional and aesthetic success in woodworking. By understanding the nuances of thickness ranges, slicing methods, and application techniques, buyers can make informed decisions that elevate their projects. Whether crafting a delicate furniture piece or designing a durable interior surface, the right veneer thickness transforms raw wood into a masterpiece of craftsmanship.

Why Handmade Wood Products Remain a Popular Choice for Buyers

You may want to see also

Explore related products

$8.99

Leaf in Wood Types: Specific to certain woods like leaf maple, known for unique grain

The term "leaf" in wood refers to a distinctive grain pattern found in specific wood types, most notably leaf maple. This pattern resembles the veins of a leaf, creating a visually striking and highly sought-after aesthetic. Unlike the straight, uniform grains of woods like oak or pine, leaf maple’s grain swirls and curls, giving each piece a one-of-a-kind appearance. This uniqueness makes it a premium choice for furniture, veneers, and decorative woodworking projects where visual appeal is paramount.

To identify leaf maple, look for its signature curly or "fiddleback" grain, which appears as tight, undulating lines across the wood surface. This pattern is not just decorative; it also adds depth and texture, enhancing the tactile and visual experience of the finished piece. However, working with leaf maple requires precision. Its irregular grain can make it prone to tear-out during cutting or sanding, so sharp tools and a light touch are essential. For best results, use a high-tooth-count blade or sandpaper to minimize damage to the delicate grain.

While leaf maple is the most famous example, other woods can exhibit leaf-like patterns under specific conditions. For instance, certain cuts of walnut or cherry may display subtle leaf-like figures, though these are less pronounced than in maple. When purchasing wood with a leaf pattern, inspect the boards carefully to ensure the grain is consistent and free of defects. Additionally, consider the wood’s intended use—leaf maple’s dramatic grain may overpower small or minimalist designs, so pair it with projects that highlight its natural beauty.

For those new to working with leaf-grained woods, start with smaller projects like boxes or wall art to familiarize yourself with the material’s behavior. Avoid using excessive force or heat, as both can distort the grain. Finishing techniques like oil or wax can enhance the depth of the leaf pattern, while polyurethanes may dull its natural luster. Finally, remember that leaf-grained woods are often more expensive due to their rarity and visual appeal, so plan your project budget accordingly. With the right approach, leaf maple and similar woods can transform ordinary pieces into extraordinary works of art.

Discover the Best Sources to Buy Authentic Brazilian Wood Today

You may want to see also

Explore related products

$1.45

Leaf in Pricing: Higher-grade leaf veneers increase wood product costs significantly

In the world of woodworking and furniture making, the term "leaf" refers specifically to thin slices of wood, often used as veneers to enhance the aesthetic appeal and quality of wood products. These veneers are not just decorative; they play a significant role in determining the cost of the final product. Higher-grade leaf veneers, in particular, can increase the price of wood products significantly, making them a critical factor for both manufacturers and consumers to consider.

To understand why higher-grade leaf veneers command a premium, it’s essential to examine their production process. These veneers are typically sourced from rare or exotic wood species, which are meticulously sliced to a thickness of 0.5 to 3 millimeters. The precision required to achieve uniform thickness and preserve the wood’s natural grain patterns adds to the cost. For example, veneers from species like mahogany, walnut, or burl can cost anywhere from $5 to $50 per square foot, depending on rarity and quality. In contrast, lower-grade veneers from more common woods may only cost $1 to $3 per square foot. This price disparity directly translates to the overall cost of the wood product.

When selecting wood products, consumers should be aware that the presence of higher-grade leaf veneers often indicates superior craftsmanship and durability. These veneers are less prone to warping or cracking over time, making them a worthwhile investment for long-term use. However, the added cost can be a deterrent for budget-conscious buyers. To strike a balance, consider the intended use of the product. For high-traffic areas like dining tables or cabinetry, investing in higher-grade veneers may be justified. For less visible or less frequently used items, opting for mid-grade veneers can provide a cost-effective alternative without sacrificing too much on quality.

Manufacturers, on the other hand, must carefully weigh the benefits of using higher-grade leaf veneers against their impact on pricing. While these veneers can elevate the perceived value of a product, they may also limit the target market to higher-end consumers. One strategy to mitigate this is to offer tiered product lines, with varying grades of veneers to cater to different price points. For instance, a furniture maker might offer a premium line featuring exotic veneers alongside a more affordable line using domestic wood species. This approach ensures accessibility while maintaining the option for luxury.

In conclusion, the term "leaf" in wood pricing is synonymous with quality and cost. Higher-grade leaf veneers are a testament to the artistry and precision involved in woodworking, but they come at a price. Whether you’re a consumer or a manufacturer, understanding the implications of leaf veneers allows for informed decisions that align with both aesthetic aspirations and budgetary constraints. By recognizing the value these veneers bring, you can navigate the market more effectively and appreciate the craftsmanship behind every piece of wood.

Cathie Wood's Weekly Trades: Latest Buys and Sells Revealed

You may want to see also

Explore related products

Leaf Durability: Quality of leaf veneer impacts long-term wear and maintenance needs

The term "leaf" in woodworking refers to a thin slice of wood, often used as a veneer to enhance the appearance of furniture, cabinetry, or flooring. When buying wood products, understanding the quality of the leaf veneer is crucial, as it directly influences durability, aesthetics, and maintenance requirements. A high-quality leaf veneer not only elevates the visual appeal but also ensures longevity, reducing the need for frequent repairs or replacements. Conversely, inferior leaf veneers may peel, crack, or fade prematurely, diminishing both the value and functionality of the piece.

Consider the environment where the wood will be used. High-traffic areas like kitchen countertops or flooring demand leaf veneers with superior durability, such as those made from hardwoods like oak or maple. Softer woods or low-quality veneers may wear quickly under constant use, leading to unsightly damage. For example, a dining table with a poorly adhered leaf veneer might develop bubbles or delamination after just a few years, while a well-crafted veneer could last decades with minimal care. Always assess the intended use and select veneers rated for the specific demands of the space.

Maintenance needs vary significantly based on leaf veneer quality. Premium veneers often feature protective finishes that resist stains, scratches, and moisture, reducing the frequency of upkeep. For instance, a polyurethane-coated veneer requires only occasional dusting and wiping with a damp cloth, whereas an untreated or low-grade veneer may need regular polishing or refinishing to maintain its appearance. Investing in higher-quality leaf veneers upfront can save time and money in the long run by minimizing maintenance efforts and extending the product’s lifespan.

To ensure you’re getting a durable leaf veneer, inspect the product closely. Look for even color, smooth surfaces, and secure adhesion to the substrate. Ask the seller about the wood species, finishing process, and expected lifespan. For example, veneers made from exotic woods like teak or walnut often offer greater durability but come at a higher cost. If budget is a concern, opt for mid-range hardwood veneers with reputable finishes, striking a balance between affordability and longevity. Remember, the quality of the leaf veneer is a direct investment in the wood’s performance and appearance over time.

Finally, consider the environmental impact of your choice. Sustainably sourced leaf veneers not only support ethical forestry practices but often correlate with higher quality, as responsible manufacturers prioritize durability to reduce waste. Look for certifications like FSC (Forest Stewardship Council) when purchasing wood products. By choosing durable, high-quality leaf veneers, you contribute to both the longevity of your furniture and the health of the planet, making it a decision that benefits both your home and the environment.

DIY Bed Frame: Where to Buy Wood Pallets for Your Project

You may want to see also

Frequently asked questions

In woodworking, "leaf" typically refers to a thin, flat piece of wood used for decorative purposes, such as in veneers, inlays, or marquetry. It is not a term used to describe the main structural wood but rather an added layer for aesthetic appeal.

Yes, "leaf" is often synonymous with wood veneer, which is a thin slice of wood glued to a thicker substrate to achieve the look of solid wood at a lower cost.

The durability of a wood product with a "leaf" or veneer depends on the quality of the veneer and the substrate. High-quality veneers can be durable, but they are more prone to damage from moisture or impact compared to solid wood.

No, "leaf" or veneer is primarily decorative and not suitable for structural applications. It is too thin to provide strength and is typically applied to a stronger base material.