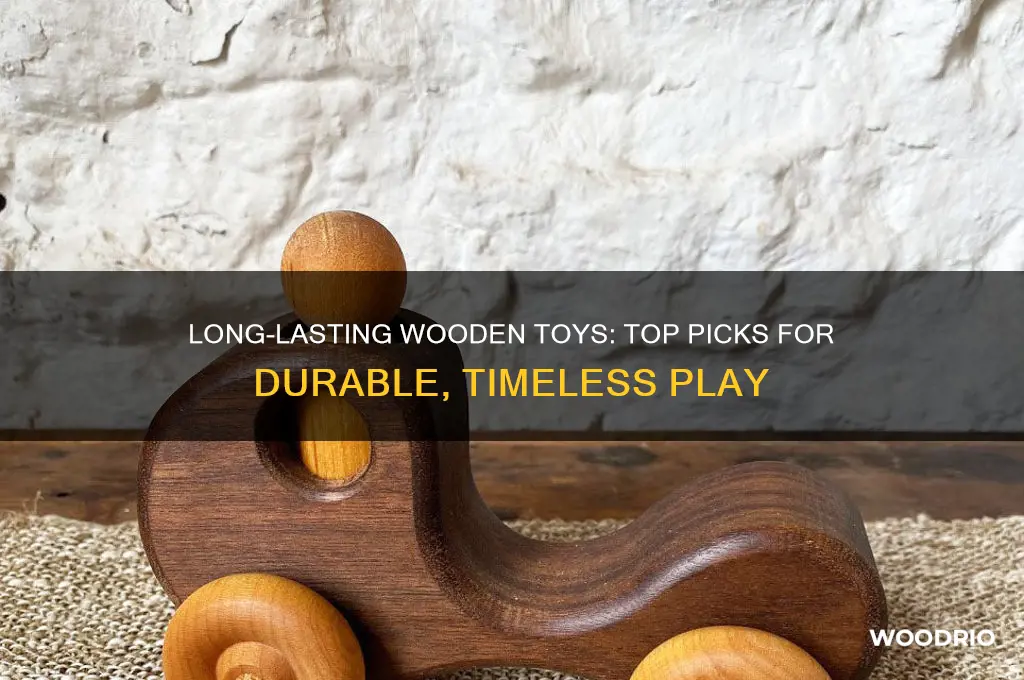

When selecting wooden toys for long-term play, durability is a key factor to ensure they withstand the test of time and rough handling. High-quality wooden toys made from hardwoods like maple, beech, or oak tend to be the most durable due to their dense and sturdy nature. Additionally, toys crafted with non-toxic, water-based finishes and secure joinery, such as dovetail or mortise-and-tenon joints, offer enhanced resilience against wear and tear. Brands that prioritize sustainability and craftsmanship, often using FSC-certified wood, are more likely to produce toys that remain intact and functional for years, making them ideal for families seeking eco-friendly and long-lasting play options.

Explore related products

$5.82 $6.99

What You'll Learn

- Hardwood vs. Softwood: Comparing durability and longevity in different wood types for toys

- Non-Toxic Finishes: Ensuring safe, long-lasting coatings for wooden toys

- Joinery Techniques: How strong joints enhance toy durability over time

- Weight and Density: Impact of wood density on toy resilience

- Maintenance Tips: Simple care practices to extend wooden toy lifespan

Hardwood vs. Softwood: Comparing durability and longevity in different wood types for toys

Hardwood and softwood, though both derived from trees, exhibit distinct properties that significantly impact their durability and suitability for wooden toys. Hardwoods, such as maple, oak, and beech, are denser and more resistant to wear and tear, making them ideal for toys that endure rough play. Softwoods, like pine and cedar, are lighter and easier to work with but tend to dent and scratch more easily. For parents and caregivers seeking toys that last through multiple childhoods, understanding these differences is crucial.

Consider the intended use of the toy when choosing between hardwood and softwood. Hardwood toys, such as building blocks or train sets, are better suited for toddlers and preschoolers who may chew, throw, or drag them across surfaces. Their density ensures they withstand repeated impacts without splintering. Softwood toys, on the other hand, are more appropriate for older children engaged in imaginative play, like dollhouses or puzzles, where the risk of rough handling is lower. However, softwoods can still be durable if properly finished with non-toxic sealants to enhance their resistance to moisture and scratches.

A practical tip for maximizing longevity is to inspect toys regularly for signs of wear, especially in high-contact areas like edges and corners. Hardwood toys may develop minor scratches but rarely lose structural integrity, while softwood toys may require more frequent repairs or replacements. For both types, avoid exposing them to extreme conditions, such as direct sunlight or damp environments, as this can cause warping or cracking. Applying a natural oil finish every six months can help maintain the wood’s integrity and appearance.

From an environmental perspective, hardwoods are often sourced from slower-growing trees, making them less sustainable than fast-growing softwoods. However, their durability can offset this by reducing the need for frequent replacements. When selecting wooden toys, look for certifications like FSC (Forest Stewardship Council) to ensure the wood is responsibly harvested. Pairing sustainability with durability ensures the toy not only lasts but also aligns with eco-conscious values.

In conclusion, the choice between hardwood and softwood depends on the toy’s purpose, the child’s age, and the desired lifespan. Hardwoods offer unmatched durability for high-impact play, while softwoods provide a lightweight, cost-effective option for gentler use. By understanding these differences and implementing proper care, caregivers can invest in wooden toys that stand the test of time, fostering both play and sustainability.

Yellowjackets' Survival: Unraveling the Length of Their Harrowing Woods Ordeal

You may want to see also

Explore related products

$29.26 $39.55

Non-Toxic Finishes: Ensuring safe, long-lasting coatings for wooden toys

Wooden toys are cherished for their timeless appeal and durability, but their longevity and safety hinge on the finishes applied. Non-toxic coatings are essential to protect both the toy’s surface and the child’s health, as children often mouth or handle toys for extended periods. Traditional finishes like lead-based paints or VOC-heavy varnishes pose risks, including developmental delays and respiratory issues. Opting for non-toxic finishes ensures the toy remains safe for all age groups, from infants to older children, while preserving its structural integrity.

Analyzing Non-Toxic Finish Options

Water-based sealants and natural oils like linseed, tung, or coconut oil are top choices for non-toxic finishes. These options penetrate wood fibers, enhancing durability without forming a surface film that can chip or peel. For example, beeswax-based polishes provide a matte, smooth finish ideal for teething toys, as beeswax is edible and hypoallergenic. Conversely, shellac, derived from resin secretions, offers a harder finish suitable for high-wear items like building blocks. Each finish has unique properties: oils nourish the wood, waxes offer a tactile grip, and plant-based varnishes provide a glossy, protective layer.

Application Techniques for Optimal Results

Applying non-toxic finishes requires precision to ensure even coverage and adhesion. Start by sanding the wood to a 220-grit smoothness, removing any rough patches that could snag or splinter. For oil finishes, apply thin coats with a lint-free cloth, allowing 24 hours between coats for absorption. Wax polishes should be warmed slightly to ease application, then buffed to a sheen. Water-based sealants, like those made from acrylic or polyurethane, require a brush or spray application, with drying times of 2–4 hours between coats. Always test finishes on a scrap piece to confirm compatibility with the wood type.

Cautions and Maintenance Tips

While non-toxic finishes are safer, they still require careful handling. Avoid overheating natural oils during application, as this can release fumes or alter their composition. Store finished toys away from direct sunlight to prevent fading or drying out. For cleaning, use mild soap and water, avoiding harsh chemicals that could degrade the finish. Reapply oils or waxes every 6–12 months to maintain protection, especially for toys subjected to frequent washing or rough play. Regularly inspect toys for wear, sanding and refinishing as needed to extend their lifespan.

The Long-Term Value of Non-Toxic Finishes

Investing in non-toxic finishes not only safeguards children’s health but also enhances the toy’s durability and aesthetic appeal. Unlike synthetic coatings, natural finishes age gracefully, developing a patina that adds character. Parents can trust that these toys remain safe for hand-me-downs or future generations, reducing environmental impact by minimizing waste. By prioritizing non-toxic options, manufacturers and caregivers alike contribute to a healthier, more sustainable play environment. The choice of finish is as crucial as the wood itself, ensuring toys that are as enduring as they are safe.

Durability of Pine Wood Furniture: Lifespan and Maintenance Tips

You may want to see also

Explore related products

Joinery Techniques: How strong joints enhance toy durability over time

Strong joints are the unsung heroes of durable wooden toys, often determining whether a cherished plaything withstands years of rough handling or falls apart after a few tumbles. Consider the classic wooden train set: the repeated coupling and decoupling of carriages, the weight of the engine, and the inevitable crashes all place immense stress on the joints. A poorly constructed joint, like a simple butt joint held together with a single nail, will quickly loosen or break. In contrast, a dovetail or mortise-and-tenon joint, reinforced with wood glue and a dowel, distributes stress evenly and resists separation, ensuring the train remains intact for generations.

To understand why joinery matters, think of a wooden toy as a chain—only as strong as its weakest link. Joints are those links. For instance, finger joints, often used in puzzle blocks, interlock like a zipper, providing strength along the grain of the wood. However, they can weaken if the wood is not properly seasoned or if the fit is too loose. To enhance durability, manufacturers often combine finger joints with a cross-grain technique, such as a spline joint, where a thin piece of wood is inserted across the joint to prevent splitting. This hybrid approach is particularly effective in toys like stacking rings or building blocks, where repeated assembly and disassembly are common.

For parents and educators selecting wooden toys, understanding joinery techniques can be a game-changer. Look for toys with visible dovetail or box joints, which are stronger than basic butt or miter joints. Dovetail joints, for example, are self-locking due to their trapezoidal shape, making them ideal for drawers in dollhouses or toolboxes. Similarly, mortise-and-tenon joints, where a peg (tenon) fits into a hole (mortise), are excellent for structural toys like rocking horses or ladders. These joints can bear significant weight and movement without compromising stability, provided they are cut precisely and secured with non-toxic wood glue.

One often-overlooked factor is the type of wood used in conjunction with joinery. Hardwoods like maple or beech are naturally more durable than softwoods like pine, but even the strongest wood can fail if the joint is weak. For toys intended for children under 3, who tend to mouth objects, ensure the joints are tight enough to prevent small parts from detaching. A simple test: try pulling the joint apart with your hands. If it budges, it’s not safe for toddlers. For older children, focus on toys with reinforced joints, such as those with wooden dowels or metal screws hidden within the design, which add an extra layer of strength without compromising aesthetics.

Finally, maintenance plays a role in preserving joint integrity. Wooden toys should be kept in dry environments to prevent wood expansion or contraction, which can loosen joints over time. If a joint does become loose, repair it promptly using wood glue and clamping it until dry. Avoid over-tightening screws, as this can strip the wood fibers. By prioritizing strong joinery and proper care, wooden toys can become heirloom pieces, enduring decades of play and passing from one generation to the next.

Understanding the Lifespan of Chemicals in Pressure-Treated Wood

You may want to see also

Explore related products

Weight and Density: Impact of wood density on toy resilience

Wood density is a critical factor in determining the durability of wooden toys, directly influencing their resilience to wear, impact, and environmental stressors. Denser woods like maple (with a density of 660 kg/m³) and oak (700 kg/m³) inherently resist dents and cracks better than softer woods such as pine (420 kg/m³) or cedar (380 kg/m³). For toys subjected to rough play, such as building blocks or pull-along animals, opting for hardwoods ensures longevity, even when used by children aged 3–6, who are most likely to test a toy’s limits.

Consider the practical implications of weight in toy design. A wooden train made from dense beechwood (720 kg/m³) will feel sturdier and less prone to breakage compared to one crafted from balsa (140 kg/m³), but its added weight may make it less suitable for toddlers under 3, who might struggle to handle it. Manufacturers often balance density and weight by using hardwoods for structural components and lighter woods for decorative elements, ensuring both durability and usability across age groups.

To maximize resilience, parents and educators should prioritize toys made from tropical hardwoods like teak (660 kg/m³) or mahogany (680 kg/m³), which combine high density with natural oils that resist moisture and decay. For outdoor toys, such as sandpit tools or garden play sets, these woods outperform softer alternatives, maintaining their integrity even after prolonged exposure to sun, rain, and dirt. A simple test: press a fingernail into the wood’s surface—if no indentation remains, it’s dense enough for long-term use.

However, density isn’t the sole determinant of durability. Proper finishing techniques, such as sealing with non-toxic linseed oil or beeswax, enhance wood’s natural resilience by preventing moisture absorption and splintering. Pairing dense wood with rounded edges and reinforced joints further extends a toy’s lifespan, making it safe for younger children while ensuring it withstands the test of time. For instance, a hardwood puzzle with a smooth, sealed finish will outlast a softwood counterpart by years, even with daily use.

In summary, selecting wooden toys based on wood density is a strategic decision that pays dividends in durability. By understanding the relationship between weight, density, and resilience, caregivers can invest in toys that not only endure years of play but also provide a tactile, natural experience for children. Prioritize hardwoods for high-impact toys, balance weight for younger users, and always opt for quality finishes to safeguard both the toy and the child.

Acclimating Engineered Wood: Essential Timeframe for Perfect Installation

You may want to see also

Explore related products

$4.59 $5.75

Maintenance Tips: Simple care practices to extend wooden toy lifespan

Wooden toys, when properly cared for, can withstand decades of play, becoming cherished heirlooms rather than landfill fodder. Their durability hinges not just on material quality but on consistent, mindful maintenance. Think of it as nurturing a living thing—wood, after all, is organic and responds to its environment. Neglect leads to cracking, warping, or dullness, while attentive care preserves vibrancy and structural integrity.

Step 1: Clean with Intentional Gentleness

Harsh chemicals or excessive water are wood’s adversaries. For routine cleaning, use a barely damp microfiber cloth to wipe surfaces, removing dust, crumbs, or sticky residues. For stubborn grime, dilute mild dish soap in water (1:10 ratio), apply sparingly with a sponge, and immediately dry with a soft towel. Avoid submerging toys in water—wood fibers swell and contract, causing splits. For teething toddlers’ toys, opt for food-grade mineral oil or beeswax-based balms instead of chemical sanitizers.

Step 2: Condition to Combat Dryness

Wood is hygroscopic, meaning it absorbs and releases moisture based on its environment. In dry climates or heated homes, toys may crack without intervention. Every 3–6 months, apply a thin layer of organic tung oil or coconut oil to replenish natural oils. For moving parts (like puzzle pieces or train tracks), rub a graphite pencil tip into joints to reduce friction without attracting dust. Skip petroleum-based products, which can yellow surfaces over time.

Step 3: Store Strategically

Sunlight and temperature swings are silent destroyers. Store toys in breathable cotton bags or low, open shelves away from radiators, vents, or windows. For stackable blocks or nested shapes, alternate stacking directions monthly to prevent permanent impressions. If storing long-term, wrap toys in acid-free tissue paper and place silica gel packets nearby to control humidity.

Cautionary Notes: What to Avoid

Resist the urge to "fix" damage with glue—most wood glues contain formaldehyde, which can off-gas around children. Instead, sand minor splinters with 220-grit paper, then recondition. Never use silicone-based polishes, which leave a slippery residue hazardous for small hands. For painted toys, inspect annually for chipping; if found, seal with non-toxic wood sealant rather than repainting, which can obscure original craftsmanship.

The Longevity Mindset

Maintenance isn’t merely about preservation—it’s about respect for the material’s story. Each cleaning, oiling, or repair session becomes part of the toy’s history, deepening its sentimental value. By investing 15 minutes quarterly in care, you ensure these toys remain safe, beautiful, and functional for generations. After all, a well-maintained wooden toy doesn’t just survive—it thrives, becoming a testament to timeless play.

Composting Wood: Understanding the Natural Breakdown Process and Timeline

You may want to see also

Frequently asked questions

Wooden toys are highly durable due to their natural strength, resistance to wear and tear, and ability to withstand rough play. Hardwoods like maple, beech, and oak are particularly long-lasting, and when properly finished with non-toxic sealants, they resist moisture and scratches, ensuring longevity.

Simple, well-constructed wooden toys like building blocks, puzzles, and pull-along animals are among the most durable. Avoid toys with small, glued parts or intricate designs, as these can break more easily. Look for solid wood pieces with minimal joints and high-quality craftsmanship.

To maintain durability, regularly inspect toys for loose parts or splinters, and sand or repair them as needed. Keep toys away from extreme moisture or heat, and clean them with a damp cloth and mild soap. Applying a natural wood conditioner periodically can also help preserve their finish and strength.