Wood's durability in saltwater is a critical consideration for marine construction, boat building, and coastal infrastructure, as it directly impacts longevity and maintenance requirements. When exposed to saltwater, wood undergoes various degradation processes, including rot, corrosion, and erosion, primarily due to the presence of moisture, salt, and marine organisms. The lifespan of wood in saltwater depends on factors such as the wood species, treatment methods, environmental conditions, and the specific application. Hardwoods like teak and oak, known for their natural resistance to decay, can last decades, while softer woods may deteriorate within a few years without proper preservation techniques. Understanding these variables is essential for selecting the right materials and treatments to maximize wood's resilience in marine environments.

| Characteristics | Values |

|---|---|

| Type of Wood | Hardwoods (e.g., teak, oak) last longer than softwoods (e.g., pine, cedar) due to higher natural oils and density. |

| Duration in Saltwater | Untreated wood: 1-5 years; Treated wood (e.g., pressure-treated, marine-grade): 10-30+ years. |

| Factors Affecting Durability | Salinity levels, temperature, oxygen exposure, water movement, and biological activity (e.g., marine borers, fungi). |

| Preservation Methods | Pressure treatment, creosote coating, epoxy resins, and using naturally rot-resistant woods. |

| Environmental Impact | Saltwater accelerates decay due to osmotic pressure, chloride ion penetration, and increased biological activity. |

| Common Applications | Docks, pilings, boat hulls, and coastal structures. |

| Maintenance Requirements | Regular inspection, cleaning, and reapplication of protective coatings to extend lifespan. |

| Latest Research | Advances in composite materials and eco-friendly preservatives are improving wood longevity in saltwater environments. |

Explore related products

$13.05 $14.77

What You'll Learn

Factors Affecting Wood Durability

Wood submerged in saltwater faces a unique set of challenges that accelerate its deterioration. Unlike freshwater environments, saltwater introduces corrosive salts and marine organisms that actively break down wood fibers. While some species, like teak and cedar, exhibit natural resistance due to their dense structure and protective oils, even these will eventually succumb without intervention. Understanding the factors influencing wood durability in saltwater is crucial for anyone building docks, boats, or coastal structures.

Marine borers, microscopic organisms that feed on wood, pose a significant threat. These creatures, including shipworms and gribbles, can reduce a wooden structure to a hollow shell within years. Their activity is particularly intense in warm, shallow waters with high nutrient levels. To combat this, consider using naturally resistant woods like greenheart or applying protective coatings specifically designed to deter marine borers.

The salinity of the water directly impacts wood's lifespan. Higher salt concentrations accelerate corrosion and increase the activity of marine organisms. In areas with fluctuating salinity, such as estuaries, wood experiences additional stress from the constant change in osmotic pressure. Regular monitoring of salinity levels and choosing wood species suited to the specific salinity range can mitigate these effects.

For optimal durability, consider pressure-treating wood with preservatives like chromated copper arsenate (CCA). While CCA is effective, its use is restricted in some applications due to environmental concerns. Alternatives like alkaline copper quaternary (ACQ) offer a more environmentally friendly option, though they may require more frequent reapplication.

Finally, sunlight and temperature play a crucial role. Ultraviolet (UV) radiation from the sun breaks down wood fibers and fades finishes. In saltwater environments, where structures are often exposed to direct sunlight, UV protection is essential. Applying UV-resistant coatings and regularly inspecting for signs of weathering can significantly extend the life of wooden structures. Additionally, warmer temperatures accelerate both biological and chemical degradation processes, making regular maintenance even more critical in tropical climates.

Burnt Wood Durability: Does Charred Timber Outlast Untreated Wood?

You may want to see also

Explore related products

$19.38 $20.91

Types of Wood in Saltwater

Wood's longevity in saltwater hinges on its natural resistance to decay, a trait that varies dramatically across species. Dense, oily woods like teak and cedar excel in marine environments due to their high resin content, which acts as a natural barrier against moisture infiltration and fungal growth. Teak, for instance, contains silica and natural oils that repel water and resist warping, making it a staple in shipbuilding for centuries. Cedar, with its aromatic oils, similarly deters pests and fungi, though it’s slightly less durable than teak in prolonged saltwater exposure. These woods can last 15 to 50 years in saltwater without treatment, depending on environmental factors like temperature and water movement.

Contrastingly, softwoods like pine and fir fare poorly in saltwater due to their porous structure and low resin content. Without protective treatments like pressure-treating or epoxy coating, these woods can degrade within 1 to 5 years, as saltwater accelerates rot and insect damage. However, when treated with preservatives like chromated copper arsenate (CCA), pine can survive 10 to 15 years in saltwater, though environmental concerns limit CCA’s use today. For temporary or low-impact applications, softwoods can be cost-effective but require vigilant maintenance.

Tropical hardwoods such as ipe and mahogany offer a middle ground, combining density with natural oils to resist decay. Ipe, often called ironwood, is so dense that it’s nearly impervious to moisture, lasting 40 to 75 years in saltwater. Mahogany, while slightly less durable, still outperforms most woods with its interlocking grain and resinous properties, enduring 25 to 40 years. Both are premium choices for docks, pilings, and boatbuilding, though their high cost and weight limit accessibility.

For those seeking sustainable options, modified woods like acetylated wood are emerging as viable alternatives. This process chemically alters wood fibers to reduce moisture absorption, enabling species like pine or ash to last 20 to 30 years in saltwater. While more expensive upfront, modified woods reduce long-term maintenance and environmental impact, making them ideal for eco-conscious projects.

In practice, selecting the right wood involves balancing durability, cost, and environmental impact. For high-stress applications like seawalls or boat hulls, invest in teak or ipe. For temporary structures or budgets, treated softwoods or modified woods offer practical solutions. Always consider local conditions—warmer waters accelerate decay, while stagnant environments promote fungal growth. Regular inspections and proactive maintenance, such as re-sealing or cleaning, can extend any wood’s lifespan in saltwater.

Treated Wood Lifespan: Factors Affecting Durability and Longevity Explained

You may want to see also

Explore related products

Preservation Techniques for Wood

Wood submerged in saltwater faces rapid degradation due to moisture absorption, fungal growth, and salt crystallization. However, specific preservation techniques can significantly extend its lifespan. One effective method is pressure treatment with copper azole (CA-B), a preservative that penetrates deep into the wood fibers, inhibiting decay and insect damage. Studies show CA-B-treated wood can last up to 40 years in saltwater environments, making it ideal for marine structures like pilings and docks. Application requires professional equipment to ensure even distribution, with a recommended retention level of 0.6 pounds per cubic foot for optimal protection.

For those seeking eco-friendly alternatives, thermal modification offers a chemical-free solution. This process involves heating wood to temperatures between 392°F and 482°F in a controlled environment, altering its cellular structure to resist moisture and decay. Thermally modified wood can last 25–30 years in saltwater, though it may darken in color and become slightly brittle. This technique is particularly suited for decorative elements like boat interiors or seaside furniture, where structural integrity is less critical.

Another innovative approach is epoxy encapsulation, which involves coating wood with a thick layer of epoxy resin. This creates a waterproof barrier that shields the wood from saltwater intrusion and UV damage. While labor-intensive, epoxy-coated wood can endure for 50+ years in harsh marine conditions. For best results, ensure the wood is completely dry before application and use a marine-grade epoxy with a mixing ratio of 5:1 (resin to hardener). This method is ideal for high-moisture areas like boat hulls or underwater supports.

Comparatively, creosote treatment, once popular for marine applications, has fallen out of favor due to environmental concerns and toxicity. While creosote-treated wood can last 30–50 years in saltwater, its use is now restricted in many regions. Modern alternatives like micronized copper azole (MCA) provide similar durability without the ecological drawbacks, making them a safer and more sustainable choice for long-term preservation.

In practice, combining techniques can yield even greater longevity. For instance, pairing thermal modification with epoxy encapsulation creates a dual defense against moisture and decay, potentially extending the wood’s lifespan to 60+ years in saltwater. However, such combinations require careful planning and execution to avoid compatibility issues between treatments. By selecting the right preservation method—or a strategic blend of methods—wood can thrive in saltwater environments far beyond its natural lifespan.

Ringworm Survival in Wood: Understanding Its Lifespan and Risks

You may want to see also

Explore related products

Saltwater Exposure Time Limits

Wood submerged in saltwater faces a relentless assault from both biological and chemical forces. Marine borers, microscopic organisms that feed on wood, can reduce structural integrity within months. Simultaneously, saltwater’s chloride ions accelerate corrosion of any embedded metal, creating pathways for moisture intrusion and fungal growth. Tropical hardwoods like teak or greenheart may endure 20–40 years in such conditions, but softer woods like pine disintegrate in as little as 2–5 years. The critical variable is not just species but also depth: wood below the tidal zone, constantly saturated, degrades faster than wood exposed to alternating wet-dry cycles.

To maximize longevity, limit saltwater exposure time through strategic design. For pilings or seawalls, ensure at least 12–18 inches of wood remains above the waterline to minimize continuous saturation. Apply EPA-registered wood preservatives containing copper azole or creosote, which can double lifespan by repelling borers and fungi. If using metal fasteners, opt for stainless steel or galvanized options to delay chloride-induced corrosion. For temporary structures, plan for replacement within 5–10 years, even with treated wood, as saltwater eventually compromises all organic materials.

A comparative analysis reveals that pressure-treated southern yellow pine, a common choice for docks, lasts approximately 15 years in saltwater when properly installed. In contrast, untreated oak fails within 3–7 years. However, even treated wood shows signs of borer activity after 8–10 years, indicating that no solution is permanent. Composite materials, while pricier, offer a 25–50 year lifespan with minimal maintenance, making them a cost-effective alternative for high-exposure areas.

For those seeking precise exposure limits, consider this rule of thumb: untreated wood should not be submerged in saltwater for more than 1–2 years if structural integrity is critical. Treated wood can extend this to 10–15 years, but regular inspections are mandatory. After 5 years, monitor for hairline cracks, splintering, or hollowed sections—early signs of borer damage. If more than 20% of the cross-section is compromised, replace the component immediately to prevent catastrophic failure.

In practice, combining species selection, preservative treatments, and exposure management yields the best results. For instance, a dock built with treated Douglas fir pilings, coated in epoxy resin, and designed with sacrificial anodes to mitigate metal corrosion can achieve a 20-year lifespan. However, no wood is immortal in saltwater. Plan for periodic replacement, budget accordingly, and prioritize safety inspections every 3–5 years to catch degradation before it becomes dangerous.

Acclimating Engineered Wood: Essential Timeframe for Perfect Installation

You may want to see also

Explore related products

Signs of Wood Deterioration

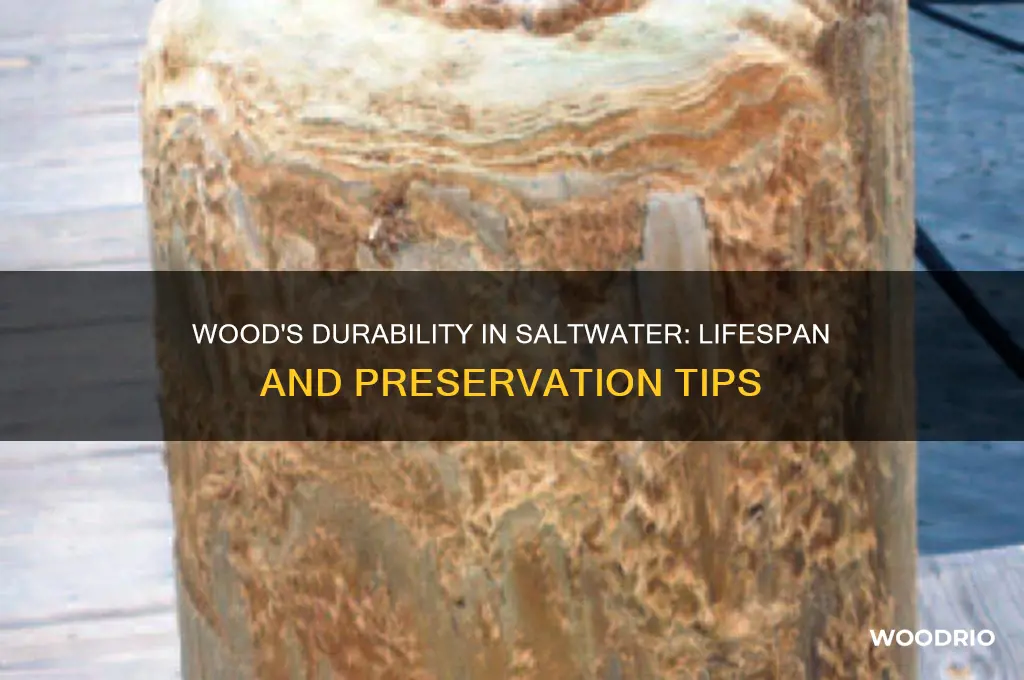

Wood exposed to saltwater faces a relentless assault from moisture, salt, and marine organisms, all of which accelerate deterioration. The first visible sign is often surface discoloration, where the wood takes on a dark, grayish hue. This occurs as the cellulose breaks down and tannins leach out, a process exacerbated by UV exposure. While this may seem purely cosmetic, it signals deeper structural changes underway. For instance, untreated pine submerged in saltwater can show discoloration within weeks, while denser hardwoods like teak may take months.

Another critical indicator is softening or crumbling texture, particularly at the wood’s surface. Run your hand over the material—if it feels spongy or flakes away under gentle pressure, the cellulose and lignin are degrading. This is often accompanied by cracking or splitting, as the wood fibers lose cohesion. In saltwater environments, this process is hastened by osmotic pressure, where salt crystals draw moisture out of the wood, causing it to shrink and fracture. A simple test: press a screwdriver tip into the wood. If it penetrates easily, the wood has lost structural integrity.

Marine borer activity leaves unmistakable signs, such as small, round exit holes or frass (sawdust-like debris) near the wood’s surface. These organisms, including shipworms and gribbles, can hollow out a wooden structure within months. For example, untreated oak pilings in tropical waters may show borer damage within 6–12 months, while treated or naturally resistant woods like greenheart can last 20+ years. Regularly inspect for these holes, especially in submerged or tidal zones, as they indicate irreversible damage.

Finally, warping or twisting is a late-stage sign of deterioration, caused by uneven moisture absorption and salt crystallization within the wood fibers. This deformation compromises the wood’s load-bearing capacity, making it unsafe for structural use. To mitigate this, monitor wood in saltwater environments quarterly, especially after storms or tidal changes. If warping exceeds 5 degrees from its original plane, consider replacing the material to prevent failure.

In summary, recognizing these signs—discoloration, texture changes, borer activity, and warping—allows for timely intervention. While no wood lasts indefinitely in saltwater, proactive inspection and treatment (e.g., pressure-treating with copper azole or using naturally resistant species) can extend its lifespan significantly.

Wooden Matches: Burn Time Secrets and Practical Uses Revealed

You may want to see also

Frequently asked questions

Wood submerged in saltwater generally lasts 10 to 20 years, depending on the type of wood and environmental conditions. Harder woods like teak or oak tend to last longer than softer woods like pine.

Yes, treating wood with preservatives, sealants, or pressure treatments can significantly extend its lifespan in saltwater, potentially doubling or tripling its durability.

Key factors include the type of wood, depth of submersion, water temperature, movement (currents or tides), and exposure to marine organisms like shipworms or barnacles.