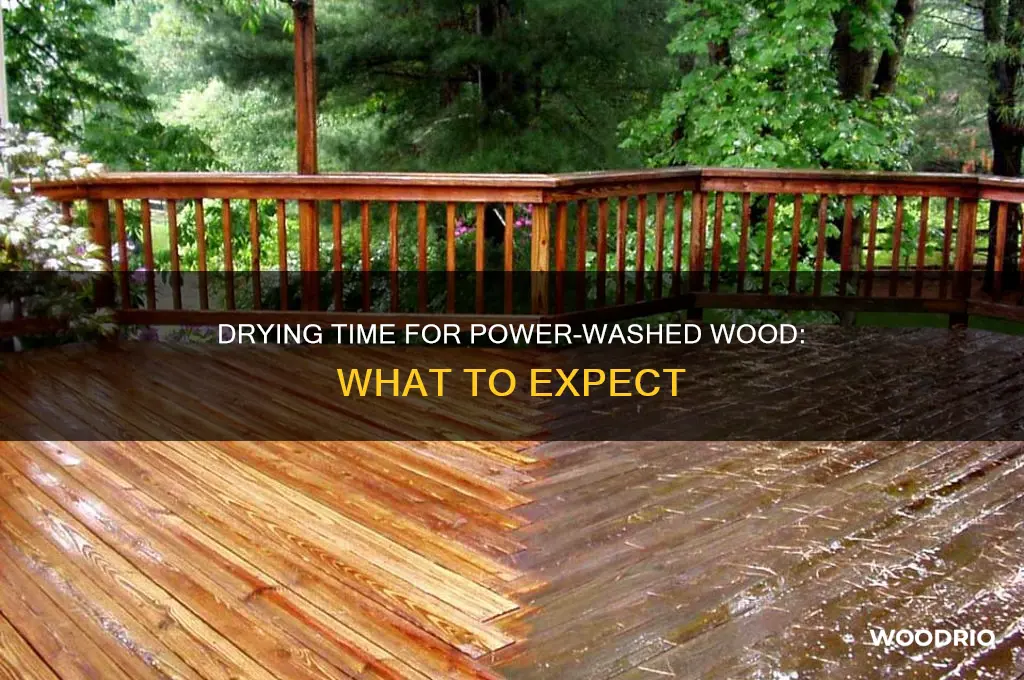

After power washing wood, the drying time can vary significantly depending on several factors, including the type of wood, weather conditions, humidity levels, and the extent of water saturation. Softwoods like pine typically dry faster, often within 24 to 48 hours in ideal conditions, while hardwoods such as oak may take 3 to 5 days or longer. High temperatures, direct sunlight, and good air circulation accelerate the process, whereas cold, damp, or humid environments can prolong it. Properly spacing the wood and ensuring it is not stacked tightly also aids in quicker drying, preventing moisture retention and potential mold or mildew growth.

| Characteristics | Values |

|---|---|

| Drying Time After Power Washing | 24 to 48 hours (depending on weather conditions and wood type) |

| Factors Affecting Drying Time | Humidity, temperature, airflow, wood density, and thickness |

| Ideal Drying Conditions | Sunny, warm, and low-humidity environment with good airflow |

| Wood Type Influence | Softwoods (e.g., pine) dry faster than hardwoods (e.g., oak) |

| Thickness of Wood | Thicker wood takes longer to dry than thinner pieces |

| Accelerating Drying Process | Use fans, dehumidifiers, or place wood in a well-ventilated area |

| Risk of Moisture Retention | Prolonged moisture can lead to mold, mildew, or warping |

| Recommended Waiting Time Before Sealing | Wait at least 48 hours to ensure wood is completely dry |

| Seasonal Impact | Summer drying times are shorter compared to winter |

| Power Washing Technique | Avoid excessive water pressure to minimize water absorption |

Explore related products

What You'll Learn

- Factors Affecting Drying Time: Sunlight, humidity, wood type, and thickness influence drying duration

- Ideal Drying Conditions: Low humidity, direct sunlight, and good airflow speed up drying

- Wood Type Variations: Hardwoods dry slower than softwoods due to denser structure

- Accelerating Drying Process: Use fans, dehumidifiers, or sealants to reduce drying time

- Signs of Fully Dried Wood: Check for consistent weight, lack of moisture, and stable texture

Factors Affecting Drying Time: Sunlight, humidity, wood type, and thickness influence drying duration

Sunlight acts as a natural catalyst in the drying process of wood after power washing. Direct exposure to sunlight accelerates evaporation by raising the wood’s surface temperature, which in turn increases the rate at which moisture escapes. For optimal results, position the wood in full sunlight during peak hours (10 a.m. to 4 p.m.). However, prolonged exposure can cause uneven drying or warping, so monitor the wood periodically. If sunlight is limited, consider using a fan or dehumidifier to supplement the drying process, mimicking the effects of natural heat.

Humidity levels play a critical role in determining how long wood takes to dry. In high-humidity environments (above 60%), moisture in the wood struggles to evaporate, prolonging drying time by up to 50%. For example, wood power-washed in a coastal region may take 48–72 hours to dry, compared to 24 hours in a drier climate. To counteract high humidity, use a moisture meter to track the wood’s moisture content, aiming for a reading below 15% for most applications. If humidity is unavoidable, apply a thin coat of breathable sealant to protect the wood while it dries.

Wood type significantly influences drying duration due to variations in density and porosity. Softwoods like pine dry faster (12–24 hours) because their open cell structure allows moisture to escape more readily. Hardwoods such as oak or teak, with denser grain patterns, may take 48–72 hours to dry completely. Always research the specific wood species you’re working with to set realistic expectations. For mixed-wood projects, separate pieces by type to ensure uniform drying and prevent moisture transfer between materials.

Thickness is a direct determinant of drying time, as moisture must travel farther to escape from thicker wood. A 1-inch thick board typically dries in 24–48 hours, while a 2-inch thick piece may require 72 hours or more. To expedite drying, consider sanding the wood lightly after power washing to open the pores, but avoid over-sanding, which can damage the surface. For thicker pieces, elevate the wood on blocks or racks to allow air circulation on all sides, reducing drying time by up to 20%.

Ash Wood Drying Time: Factors Affecting the Process and Duration

You may want to see also

Explore related products

Ideal Drying Conditions: Low humidity, direct sunlight, and good airflow speed up drying

After power washing wood, the drying time can vary significantly based on environmental conditions. Among the most influential factors are humidity, sunlight, and airflow. Low humidity is critical because moisture evaporates more readily in dry air. Aim for humidity levels below 50% for optimal drying. When humidity is high, the wood absorbs moisture from the air, prolonging the process. For instance, wood in a humid coastal area may take twice as long to dry compared to a desert climate.

Direct sunlight acts as a natural catalyst for drying. The heat from the sun accelerates evaporation, reducing drying time by up to 50%. Position the wood in full sunlight whenever possible. However, be cautious with prolonged exposure, as intense heat can cause warping or cracking. If sunlight is limited, consider using a portable heater or heat lamp to mimic its effects, maintaining a safe distance to avoid damage.

Good airflow is equally essential, as it carries moisture away from the wood surface. Ensure the wood is placed in an open area where air can circulate freely. Using fans or opening windows can enhance airflow, particularly in enclosed spaces. For larger projects, like decks or fences, angle fans to create a cross-breeze, which can cut drying time by a third. Avoid stacking or covering wet wood, as this traps moisture and slows the process.

Combining these conditions—low humidity, direct sunlight, and good airflow—creates an ideal drying environment. For example, a power-washed wooden deck in a sunny, breezy area with 40% humidity can dry within 24–48 hours, while the same deck in a shaded, humid spot might take 3–5 days. Practical tips include scheduling power washing on dry, sunny days and using weather forecasts to plan ahead. By optimizing these factors, you can significantly reduce drying time and ensure the wood is ready for staining, sealing, or use.

Drying Apple Wood: Understanding the Timeframe for Perfect Results

You may want to see also

Explore related products

Wood Type Variations: Hardwoods dry slower than softwoods due to denser structure

The drying time of wood after power washing is significantly influenced by its type, with hardwoods and softwoods exhibiting distinct behaviors. Hardwoods, such as oak, maple, and teak, possess a denser cellular structure compared to softwoods like pine, cedar, and spruce. This density directly impacts how quickly moisture evaporates from the wood fibers. After power washing, hardwoods can retain water for longer periods, often requiring 48 to 72 hours or more to dry completely, depending on environmental conditions. Softwoods, with their looser grain and lower density, typically dry within 24 to 48 hours under similar circumstances.

Consider the practical implications of this difference. If you’re working on a hardwood deck or fence, plan for an extended drying period before applying stains, sealants, or paints. Rushing this process can trap moisture within the wood, leading to warping, mold, or adhesion issues with finishes. For softwoods, while the drying time is shorter, it’s still crucial to ensure the wood is fully dry to avoid similar problems. A simple test: press a dry cloth against the wood surface. If it remains dry, the wood is ready for treatment.

Environmental factors play a critical role in drying times for both wood types. Humidity, temperature, and airflow are key determinants. In high-humidity environments, hardwoods may take up to a week to dry completely, while softwoods could still require 3–4 days. To expedite drying, position fans near the wood or use a dehumidifier indoors. Direct sunlight can also accelerate the process, but avoid prolonged exposure, as it may cause uneven drying or discoloration, particularly in softwoods.

For those seeking precise control, investing in a moisture meter is invaluable. These devices measure the wood’s moisture content, ensuring it falls within the ideal range (12–15% for most applications). Hardwoods should be monitored more closely due to their slower drying rate. If moisture levels remain high after 72 hours, consider re-evaluating the wood’s exposure to air and humidity. Softwoods, while faster-drying, should still be checked to prevent surface-level dryness masking deeper moisture retention.

In summary, understanding the inherent differences between hardwoods and softwoods is essential for effective post-power washing care. Hardwoods demand patience and vigilance, while softwoods offer a quicker turnaround but still require attention to detail. By tailoring your approach to the wood type and environmental conditions, you can ensure optimal drying and long-lasting results for your wood projects.

Wood Crossarm Lifespan: Factors Affecting Durability and Longevity

You may want to see also

Explore related products

Accelerating Drying Process: Use fans, dehumidifiers, or sealants to reduce drying time

Wood typically takes 24 to 48 hours to dry after power washing, but environmental factors like humidity and temperature can extend this timeframe. To reclaim your deck or fence faster, strategic intervention is key. Fans, dehumidifiers, and sealants aren’t just tools—they’re time-savers. By actively manipulating the drying conditions, you can cut down waiting periods and minimize the risk of warping, mold, or rot.

Step 1: Deploy Fans for Targeted Airflow

Position industrial fans or household box fans at a 45-degree angle to the wood surface, ensuring they’re at least 3 feet away to avoid blowing debris. Aim for a consistent airflow of 10–15 mph, which can reduce drying time by up to 50%. For larger areas, use oscillating fans to cover more ground. Avoid pointing fans directly at seams or cracks, as this can force water deeper into the wood grain.

Step 2: Leverage Dehumidifiers in Enclosed Spaces

In humid climates or enclosed areas like porches, a dehumidifier is essential. Set the unit to maintain a 40–50% humidity level, running it continuously until the wood feels dry to the touch. For every 100 square feet of wood, a 30-pint dehumidifier is sufficient. Pair it with fans for optimal results, as dehumidifiers alone may struggle with surface-level moisture.

Step 3: Apply Sealants Strategically

Once the wood is 80–90% dry (no longer feels cool to the touch), apply a water-repellent sealant to lock in dryness. Choose a product with a 2–3-hour drying time, such as Thompson’s WaterSeal or Olympic Elite. Avoid oil-based sealants if the wood is still damp, as they can trap moisture. Reapply sealant every 2–3 years to maintain protection against future power washes.

Cautions and Trade-offs

Overusing fans can dry the wood’s surface too quickly, causing cracking or splitting. Similarly, applying sealant prematurely traps moisture, leading to mildew. Always test a small area before full application. Dehumidifiers consume energy, so balance usage with cost considerations. For aged or weathered wood, consult a professional to avoid exacerbating existing damage.

Accelerating wood drying after power washing isn’t just about speed—it’s about precision. Fans, dehumidifiers, and sealants work in tandem to create an environment hostile to moisture. By following these steps, you’ll not only reduce drying time but also extend the lifespan of your wood surfaces, ensuring they’re ready for use or treatment sooner rather than later.

Wood Glue Shelf Life: How Long Does It Last in the Bottle?

You may want to see also

Explore related products

Signs of Fully Dried Wood: Check for consistent weight, lack of moisture, and stable texture

Wood drying after power washing is a process that varies depending on factors like humidity, temperature, and wood type. However, understanding the signs of fully dried wood is crucial to prevent issues like warping, mold, or decay. One of the most reliable indicators is consistent weight. Freshly power-washed wood retains moisture, making it heavier than its dry state. To test, weigh a small piece before and after washing, then periodically re-weigh it until the weight stabilizes. For hardwoods like oak, this may take 2–4 weeks, while softer woods like pine can dry in 1–2 weeks under optimal conditions.

Another critical sign is the lack of moisture. Visually inspect the wood for dark spots or dampness, which indicate residual water. A more precise method is using a moisture meter, aiming for a reading below 12–15% moisture content for outdoor wood and 8–10% for indoor use. If you lack a meter, press a piece of plastic wrap against the wood for 24 hours—condensation suggests it’s still drying. Avoid relying solely on surface dryness, as moisture can linger deep within the wood fibers.

A stable texture is equally important. Wet wood feels cooler and may appear swollen or rough. As it dries, it returns to its natural texture, becoming smoother and firmer. Run your hand over the surface—if it feels uniformly dry and no longer pliable, it’s likely ready. For a more rigorous test, attempt to drive a small nail into the wood; dry wood will resist penetration, while damp wood will yield more easily. This tactile assessment complements weight and moisture checks for a comprehensive evaluation.

Practical tips can expedite the drying process. Ensure the wood is in a well-ventilated area, ideally in direct sunlight, as UV rays aid evaporation. Elevate the wood off the ground using spacers to prevent moisture absorption from below. In humid climates, consider using a dehumidifier or fans to circulate air. For urgent projects, kiln-drying or using a heat gun can accelerate drying, but these methods require caution to avoid cracking or scorching. Patience, however, remains the most reliable approach, as rushing can compromise the wood’s integrity.

In summary, fully dried wood exhibits consistent weight, lacks moisture, and maintains a stable texture. By combining these checks with proactive drying techniques, you can ensure the wood is ready for staining, sealing, or use. Remember, proper drying is an investment in the wood’s longevity, preventing costly repairs down the line.

How Long Can Bacteria Survive on Wood Surfaces?

You may want to see also

Frequently asked questions

It usually takes 24 to 48 hours for wood to dry after power washing, depending on weather conditions, humidity, and the thickness of the wood.

Yes, you can speed up drying by ensuring good airflow, using fans, or placing the wood in direct sunlight. Avoid excessive heat, as it can cause warping or cracking.

No, wait until the wood is completely dry, typically 2–3 days, before applying stain or sealant to ensure proper adhesion and prevent moisture-related issues.