Canvassing an old wood canoe is a rewarding restoration project that breathes new life into a cherished piece of craftsmanship. This process involves carefully removing the old canvas and any deteriorated materials, repairing or replacing damaged wooden ribs and planks, and then applying a new layer of canvas to the hull. The canvas is typically coated with a durable marine-grade resin or paint to ensure water resistance and longevity. Attention to detail is crucial, as proper alignment, tension, and sealing of the canvas are essential for both structural integrity and aesthetic appeal. Whether preserving a family heirloom or reviving a vintage find, canvassing an old wood canoe combines traditional techniques with patience and skill to restore its beauty and functionality for years to come.

Explore related products

What You'll Learn

- Preparation: Gather tools, sandpaper, wood filler, varnish, and safety gear before starting restoration

- Cleaning: Remove dirt, old finish, and mildew using mild soap and water

- Repairing: Fix cracks, holes, and rot with wood filler or epoxy resin

- Sanding: Smooth the surface with progressively finer grits of sandpaper

- Finishing: Apply multiple coats of marine varnish for protection and shine

Preparation: Gather tools, sandpaper, wood filler, varnish, and safety gear before starting restoration

Before diving into the restoration of an old wood canoe, it's crucial to assemble the right tools and materials. Think of this as setting the foundation for a successful project. You’ll need sandpaper in various grits (80, 120, 220, and 400) to address different levels of wear and tear. Wood filler is essential for repairing cracks, holes, or imperfections in the canoe’s structure. Choose a marine-grade varnish for durability against water and UV exposure. Safety gear, including gloves, goggles, and a dust mask, is non-negotiable to protect yourself from debris and chemicals. Each item serves a specific purpose, and skipping any could compromise the quality or safety of the restoration.

Consider the analytical approach: the tools you gather directly impact the outcome. For instance, using the wrong grit sandpaper can leave scratches or fail to smooth surfaces adequately. Marine-grade varnish, while more expensive, is designed to withstand the harsh conditions a canoe faces, making it a smarter long-term investment than standard finishes. Safety gear isn’t just a formality—it prevents respiratory issues from dust inhalation and eye injuries from flying debris. By prioritizing these materials, you’re not just preparing for the task; you’re ensuring the canoe’s longevity and your well-being.

Now, let’s break it down step-by-step. Start by listing all necessary items: sandpaper, wood filler, varnish, brushes, a putty knife, and safety gear. Purchase or gather these before beginning to avoid mid-project interruptions. Organize your workspace to keep tools within reach, streamlining the process. For wood filler, opt for a product compatible with marine environments, such as epoxy-based fillers, which adhere well to wood and resist moisture. When applying varnish, ensure you have multiple clean brushes to avoid contamination between coats. This methodical approach transforms preparation from a chore into a strategic part of the restoration.

A persuasive argument for thorough preparation lies in the potential pitfalls of skipping it. Imagine sanding without goggles and inhaling wood dust, or using low-quality filler that cracks after the first outing. These scenarios aren’t just inconvenient—they’re costly and time-consuming to fix. Investing time upfront to gather the right materials saves you from headaches later. Think of it as a small price to pay for a canoe that not only looks restored but also performs like new. The effort you put into preparation directly correlates to the pride you’ll feel when the canoe glides through the water, a testament to your meticulous work.

Finally, consider the descriptive aspect of preparation: the tactile feel of sandpaper against weathered wood, the satisfying smoothness of a well-filled crack, the glossy sheen of freshly applied varnish. Each tool and material contributes to a sensory experience that goes beyond functionality. The smell of wood filler, the weight of safety goggles, the sound of sandpaper grit—these details immerse you in the process, making restoration more than a task; it’s a craft. By gathering these items thoughtfully, you’re not just preparing to restore a canoe; you’re engaging in a tradition of care and preservation that honors the vessel’s history and ensures its future.

Unveiling Scott Woods' Age: A Surprising Discovery About His Life

You may want to see also

Explore related products

Cleaning: Remove dirt, old finish, and mildew using mild soap and water

Before applying new canvas to an old wood canoe, the surface must be immaculate. Any residual dirt, old finish, or mildew will compromise adhesion and longevity. Think of it as preparing a canvas for a painting—the cleaner the surface, the truer the colors will shine. This principle applies here, where the wood’s natural beauty and structural integrity depend on thorough cleaning.

Begin with a gentle yet effective solution: mild soap and water. Avoid harsh chemicals or abrasive cleaners, as they can damage the wood’s delicate surface. Mix one tablespoon of liquid dish soap (unscented and non-bleach) with one gallon of warm water. Use a soft-bristled brush or sponge to apply the solution, working in the direction of the wood grain. For stubborn areas, let the solution sit for 5–10 minutes before scrubbing. Rinse thoroughly with clean water, ensuring no soap residue remains, as it can interfere with the new finish.

Mildew, a common issue in older canoes, requires targeted attention. If visible, create a paste of baking soda and water (3:1 ratio) and apply it directly to the affected area. Let it sit for 15 minutes, then scrub gently with a soft brush. For persistent mildew, a solution of one part white vinegar to three parts water can be sprayed on, left for 10 minutes, and rinsed. Always test these treatments on a small, inconspicuous area first to ensure they don’t harm the wood.

After cleaning, allow the canoe to dry completely. This step is critical—moisture trapped beneath the canvas or finish can lead to rot or warping. Place the canoe in a well-ventilated area, out of direct sunlight, and let it air-dry for at least 24–48 hours. Use a moisture meter to confirm the wood’s dryness, aiming for a reading below 12% moisture content. Patience here pays off, ensuring a stable foundation for the next steps in the restoration process.

By meticulously cleaning the canoe, you’re not just removing grime—you’re preserving history. This step is the cornerstone of a successful restoration, blending practicality with respect for the craft. Done correctly, it sets the stage for a canvas application that will last for generations, honoring the canoe’s past while securing its future.

Anna Wood's Age: Unveiling the Truth About Her Life and Years

You may want to see also

Explore related products

Repairing: Fix cracks, holes, and rot with wood filler or epoxy resin

Before applying canvas to an old wood canoe, the structural integrity of the hull must be addressed. Cracks, holes, and rot compromise not only the aesthetic but also the functionality and safety of the vessel. Wood filler and epoxy resin are the primary materials for these repairs, each with distinct properties suited to different types of damage. Wood filler, a putty-like substance, is ideal for shallow surface cracks and small holes, as it mimics the texture and grain of wood. Epoxy resin, on the other hand, penetrates deeper into the material, making it superior for stabilizing rot and filling voids where structural strength is critical.

When repairing rot, begin by removing all deteriorated wood with a chisel or rotary tool, ensuring the area is clean and dry. Mix epoxy resin according to the manufacturer’s instructions—typically a 1:1 or 2:1 ratio of resin to hardener—and apply it generously to the damaged section. For larger voids, use a thickened epoxy by adding wood flour or silica to create a putty-like consistency. This mixture can be molded to fill gaps and shaped to match the contour of the canoe. Allow the epoxy to cure fully, which may take 24 to 48 hours depending on the product and environmental conditions. Sand the repaired area smooth, blending it seamlessly with the surrounding wood.

For cracks, the approach varies based on their depth and location. Surface cracks can be filled with wood filler, applied in thin layers to avoid shrinkage. Deeper cracks require a more meticulous process: inject epoxy resin into the crack using a syringe to ensure it penetrates the entire length. If the crack is wide, insert wooden splines or fiberglass cloth soaked in epoxy to reinforce the joint. This method not only fills the gap but also adds tensile strength, preventing the crack from reopening under stress. Always clamp or weight the repair to maintain proper alignment during curing.

Holes present a unique challenge, particularly if they are larger than a quarter. Small holes can be filled directly with wood filler or epoxy, but larger ones require a backing material. Cut a patch of thin wood or fiberglass to fit behind the hole, then saturate it with epoxy before applying the filler or resin. This creates a solid substrate for the repair, ensuring it bonds securely to the canoe. For holes near the waterline, consider using marine-grade epoxy, which offers superior resistance to moisture and temperature fluctuations.

While repairing, prioritize precision over speed. Rushed repairs often fail, leading to further damage and additional work. Test the cured repair by tapping it with a mallet; a solid, dull sound indicates a successful bond, while a hollow sound suggests air pockets or inadequate adhesion. After sanding, seal the repaired area with a marine varnish or paint to protect it from the elements. Properly executed, these repairs not only restore the canoe’s structural integrity but also preserve its historical and aesthetic value, ensuring it remains seaworthy for years to come.

Revitalize Old Wood: A Guide to Applying Polyurethane Over Aged Surfaces

You may want to see also

Explore related products

Sanding: Smooth the surface with progressively finer grits of sandpaper

Sanding is the cornerstone of any canoe restoration, particularly when preparing for canvas application. The goal isn’t just smoothness—it’s creating a surface that allows the canvas to adhere seamlessly, ensuring longevity and structural integrity. Start with a coarse grit, such as 60 or 80, to remove old varnish, paint, or surface imperfections. This initial pass is aggressive but necessary, stripping away decades of wear and tear. Think of it as the foundation for what’s to come: a clean slate for the finer work ahead.

As you progress, the grits should become progressively finer—120, 180, and finally 220 or higher. Each grit serves a purpose, refining the surface and eliminating the scratches left by the previous one. This methodical approach ensures uniformity, preventing the canvas from catching on rough patches or absorbing unevenly. A common mistake is rushing this process, but patience here pays dividends. Spend extra time on edges and joints, where the canvas will wrap and tension will be highest.

The tactile feedback of sanding is your best guide. Run your hand over the wood after each grit to assess progress. The surface should feel progressively smoother, transitioning from rough to almost silky. For curved areas, like the hull’s exterior, use flexible sanding sponges or wrap sandpaper around a block to maintain contour consistency. Flat surfaces, such as the gunwales, benefit from a rigid sanding block for even pressure.

Caution is key when sanding older wood. Avoid over-sanding, which can thin the wood or create uneven depressions. Work in the direction of the grain to prevent splintering, and use a light touch on delicate areas. If the wood feels warm under your hand, take a break—friction from sanding can cause damage. Dust management is equally critical; use a tack cloth or damp rag between grits to remove particles that could mar the finish.

The final grit, typically 220 or higher, should leave the wood feeling glass-smooth to the touch. This is the surface the canvas will bond to, so inspect it under good light to ensure no imperfections remain. When done correctly, sanding isn’t just a preparatory step—it’s an art that bridges the old and the new, setting the stage for a canvas application that honors the canoe’s history while ensuring its future.

Matt Bangs Wood's Age: Unveiling the Mystery Behind the Legend

You may want to see also

Explore related products

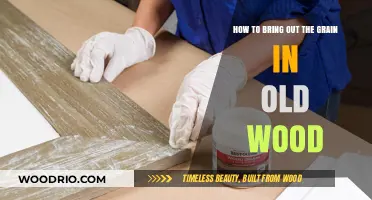

Finishing: Apply multiple coats of marine varnish for protection and shine

Marine varnish isn't just a cosmetic choice for your restored wood canoe—it's a critical shield against the elements. Sun, water, and temperature fluctuations wage war on exposed wood, leading to cracking, warping, and eventual decay. Multiple coats of marine varnish create a durable barrier, repelling moisture, blocking UV rays, and providing a sacrificial layer that can be refinished over time. Think of it as armor for your canoe, ensuring its beauty and structural integrity for years of paddling adventures.

Marine varnish application is a game of patience and precision. Start with a clean, dust-free surface, sanding between each coat to ensure a smooth, even finish. Apply thin, even coats with a high-quality brush, working in the direction of the wood grain. Allow ample drying time between coats, typically 24 hours, depending on humidity and temperature. Aim for a minimum of three coats, but five or more is ideal for maximum protection. Remember, thin coats build a more durable finish than a single thick application, which can lead to drips and uneven drying.

While marine varnish provides exceptional protection, it's not invincible. Direct sunlight remains a formidable foe, so store your canoe in a shaded area when not in use. Regularly inspect the varnish for signs of wear, such as cracking or peeling, and touch up as needed. Consider using a UV-inhibiting varnish for added sun protection, especially in harsh climates. Remember, proper maintenance extends the life of your varnish and, ultimately, your canoe.

Not all marine varnishes are created equal. Choose a high-quality, marine-grade product specifically formulated for exterior wood surfaces. Look for varnishes with UV inhibitors and flexible resins that can withstand the movement of the wood. Oil-based varnishes offer superior durability but require longer drying times, while water-based options dry faster and have lower VOC emissions. Consider your climate, storage conditions, and personal preferences when making your selection.

The final coats of marine varnish transform your restored canoe from a functional vessel into a work of art. The deep, lustrous sheen highlights the natural beauty of the wood grain, showcasing the craftsmanship and history of your canoe. As the varnish cures, the wood seems to glow, a testament to your dedication and the timeless appeal of a well-maintained wooden canoe. This final touch not only protects your investment but also inspires a sense of pride and connection to the tradition of wooden boatbuilding.

Do Black Raspberries Thrive on Old Wood? Unveiling the Truth

You may want to see also

Frequently asked questions

You will need canvas (preferably marine-grade), epoxy resin, fiberglass tape (optional), wood filler, sandpaper, brushes, a staple gun, and protective gear like gloves and a mask.

Clean the canoe thoroughly, remove any old canvas or debris, fill cracks or holes with wood filler, and sand the surface smooth. Ensure the wood is dry and free of dust before proceeding.

Start by stapling the canvas along the centerline of the canoe, working outward to avoid wrinkles. Pull the canvas tight and staple it along the gunwales, trimming excess material. Apply epoxy resin over the canvas to seal and protect it.