Changing an old wooden staircase can breathe new life into your home, enhancing both its aesthetic appeal and structural integrity. Whether you aim to modernize the design, repair worn-out steps, or improve safety, the process involves careful planning, selecting appropriate materials, and executing precise craftsmanship. From assessing the condition of the existing staircase to choosing between refinishing, replacing, or adding decorative elements, each step requires attention to detail. With the right tools, techniques, and possibly professional guidance, transforming your old wooden staircase can become a rewarding project that elevates your living space.

| Characteristics | Values |

|---|---|

| Material Options | Hardwood (oak, maple, walnut), engineered wood, laminate, carpet, tile, or painted wood |

| Structural Assessment | Inspect for rot, loose railings, squeaky steps, and uneven treads. Consult a professional if unsure. |

| Safety Considerations | Ensure proper handrail height (34-38 inches), non-slip surfaces, adequate lighting, and secure balusters. |

| Refinishing vs. Replacement | Refinishing: Sand, stain, and seal existing wood. Replacement: Remove old stairs and install new ones. |

| Tread and Riser Options | Replace individual treads or risers, add tread caps, or install new pre-made stair kits. |

| Railings and Balusters | Update with new styles (modern, traditional), materials (metal, glass), or simply refinish existing ones. |

| Cost | Refinishing: $500 - $2,500. Replacement: $1,500 - $10,000+ depending on materials and complexity. |

| DIY vs. Professional | Simple refinishing can be DIY, but structural changes and complex installations require professional expertise. |

| Timeframe | Refinishing: 2-5 days. Replacement: 1-2 weeks or more. |

| Permits | Check local building codes for permit requirements, especially for structural changes. |

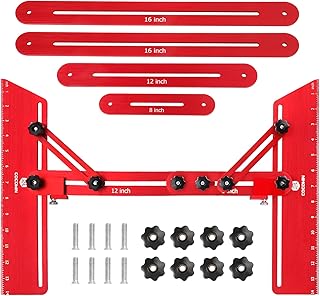

Explore related products

What You'll Learn

- Assess Staircase Condition: Inspect for damage, rot, loose parts, stability, and safety concerns before starting repairs

- Remove Old Finishes: Strip paint, varnish, or stains using chemical strippers or sanding tools carefully

- Repair or Replace: Fix broken treads, risers, or balusters; replace irreparable parts with matching wood

- Sand and Smooth: Use sandpaper to smooth surfaces, ensuring a clean base for new finishes

- Apply New Finish: Stain, paint, or seal the staircase to enhance appearance and protect the wood

Assess Staircase Condition: Inspect for damage, rot, loose parts, stability, and safety concerns before starting repairs

Before diving into any renovation, understanding the current state of your staircase is paramount. A thorough inspection will reveal not only the extent of wear and tear but also potential hazards that could compromise safety. Start by examining each step for signs of damage, such as cracks, splinters, or warping. Pay close attention to areas where foot traffic is highest, as these are more prone to deterioration. Use a flashlight to inspect dark corners and undersides, ensuring no issue goes unnoticed.

Rot is a silent destroyer of wooden structures, often hidden beneath the surface. To detect it, press a screwdriver gently into the wood at various points. If it sinks in easily, the wood is likely compromised. Focus on areas exposed to moisture, such as near windows or exterior doors, as these are prime spots for rot to develop. Additionally, check for discoloration or a musty odor, which are telltale signs of fungal growth. Addressing rot early can prevent structural failure and costly repairs down the line.

Loose parts pose immediate safety risks and should be identified and secured promptly. Wiggle each baluster, handrail, and tread to test their stability. Listen for squeaks or creaks, which often indicate loose nails or screws. For a more thorough assessment, use a level to check if the staircase is plumb and even. Uneven steps or a wobbly handrail not only detract from the aesthetic but also increase the risk of accidents. Keep a list of all issues to prioritize repairs effectively.

Stability is the backbone of a safe staircase. Inspect the stringers—the diagonal supports on either side—for signs of weakness or damage. Ensure they are firmly attached to the wall and floor. If the staircase feels shaky when walked upon, this could indicate a deeper structural issue. Consider consulting a professional if you suspect significant instability, as reinforcing or replacing stringers may require specialized tools and expertise.

Finally, adopt a safety-first mindset throughout the inspection process. Wear protective gear, such as gloves and safety goggles, to avoid injuries from splinters or debris. If the staircase is severely damaged, restrict access to prevent accidents until repairs can be made. Document your findings with photos and notes, which will serve as a valuable reference during the renovation. By meticulously assessing the condition of your staircase, you lay the foundation for a successful and safe transformation.

Unveiling the Timeless Majesty: Age of Ancient Redwood Trees

You may want to see also

Explore related products

Remove Old Finishes: Strip paint, varnish, or stains using chemical strippers or sanding tools carefully

Before embarking on the transformation of your old wooden staircase, it's essential to start with a clean slate. This means removing any existing finishes that may be hiding the natural beauty of the wood or hindering the adhesion of new coatings. Paint, varnish, and stains can accumulate over decades, often in multiple layers, making this step both crucial and labor-intensive. The goal is to expose the bare wood, ensuring that any new finish or treatment will bond effectively and last longer.

Chemical strippers are a popular choice for this task, as they can dissolve old finishes without the need for excessive manual labor. When using these products, it’s vital to choose one that’s suitable for the type of finish you’re removing. For instance, paint strippers are formulated differently than those for varnish. Apply the stripper generously with a brush, allowing it to sit for the recommended time—usually 15 to 30 minutes, depending on the product. Use a scraper to remove the softened finish, working in the direction of the wood grain to avoid damage. Always wear protective gear, including gloves and goggles, and ensure proper ventilation to avoid inhaling fumes.

For those who prefer a more hands-on approach or are dealing with stubborn finishes, sanding is an effective alternative. Start with a coarse-grit sandpaper (60-80 grit) to break through the top layers, then progress to finer grits (120-220 grit) to smooth the surface. Power sanders, such as belt or orbital sanders, can expedite the process, but be cautious not to over-sand, as this can unevenly wear down the wood. Hand sanding in tight corners and intricate details is often necessary to achieve a uniform finish. Remember, sanding generates dust, so use a dust mask and consider attaching a vacuum to your sander for cleaner air.

Comparing the two methods, chemical stripping is faster and less physically demanding but requires careful handling of toxic substances. Sanding, while more laborious, gives you greater control over the process and avoids the use of chemicals. The choice depends on your comfort level, the condition of the staircase, and the tools at your disposal. Whichever method you choose, the key is patience—rushing this step can lead to incomplete removal or damage to the wood, compromising the final result.

A practical tip for stubborn areas is to combine both techniques. Apply a chemical stripper to particularly resistant spots, let it work, and then sand the area to ensure all residue is removed. After stripping, clean the wood thoroughly with a damp cloth to remove any remaining chemicals or dust. This prepares the surface for the next steps, whether it’s staining, painting, or sealing. By meticulously removing old finishes, you’re not just restoring the staircase—you’re setting the foundation for a durable and aesthetically pleasing transformation.

Terry Wood Anchor's Age: Unveiling the Mystery Behind the News Personality

You may want to see also

Explore related products

Repair or Replace: Fix broken treads, risers, or balusters; replace irreparable parts with matching wood

Before diving into a full staircase overhaul, assess the damage. Are the treads worn but structurally sound? Do the risers have minor cracks or splits? Is a single baluster wobbly, or are several broken? Minor issues like surface scratches, small cracks, or loose screws often respond well to repair. For treads, sanding and refinishing can restore their appearance, while wood filler can address small gaps or chips. Risers with minor damage might only need a patch or a brace. Balusters that are loose but intact can often be re-secured with epoxy or by tightening the fasteners.

When damage is extensive, replacement becomes necessary. Treads with deep cracks, rot, or severe warping compromise safety and should be replaced. Risers with large holes or structural weakness cannot be reliably repaired. Balusters that are broken, splintered, or missing entirely need to be swapped out. When replacing parts, sourcing matching wood is critical. Take samples of the existing wood to a supplier to find a close match in species, grain pattern, and color. If the original wood is rare or discontinued, consider refinishing the entire staircase to blend new and old elements seamlessly.

Replacing parts requires precision. For treads, measure the length, width, and thickness of the original piece, ensuring the new tread fits snugly into the stringer grooves. Use a circular saw to cut the replacement to size, and pre-drill holes to avoid splitting the wood. Risers demand careful alignment to maintain a uniform height and plumbness. Secure them with screws or nails, ensuring they are flush with the treads and stringers. Balusters must be cut to the correct height and angle, especially on curved or angled staircases. Use a level to ensure they are plumb before securing them with wood glue and screws.

While repairing or replacing parts is cost-effective compared to a full renovation, it’s not without challenges. Matching the wood’s patina or stain can be difficult, especially on older staircases. Handrails and balusters often have intricate profiles that are hard to replicate. If the staircase is part of a historic home, consult preservation guidelines to ensure changes are sympathetic to the original design. For safety, always follow building codes regarding tread depth, riser height, and baluster spacing. When in doubt, hire a professional carpenter to ensure structural integrity and aesthetic harmony.

The decision to repair or replace hinges on the extent of the damage and your long-term goals. Minor repairs extend the life of the staircase with minimal cost and effort, while strategic replacements address safety hazards and maintain functionality. By carefully assessing each component and choosing materials thoughtfully, you can preserve the character of an old wooden staircase while ensuring it remains a safe and beautiful feature of your home. Whether you tackle the project yourself or enlist help, the result is a staircase that blends old-world charm with modern durability.

Unveiling Ramone Woods' Age: A Comprehensive Look at His Life

You may want to see also

Explore related products

Sand and Smooth: Use sandpaper to smooth surfaces, ensuring a clean base for new finishes

The first step in transforming an old wooden staircase is to strip away the past, and sandpaper is your most trusted ally in this endeavor. Begin with a medium-grit sandpaper, such as 80 or 100 grit, to remove old paint, varnish, or stains. This initial pass is about aggression—breaking through the surface to reveal the raw wood beneath. Work methodically, following the grain of the wood to avoid scratches or damage. For tight corners and intricate details, consider using sanding blocks or even folded sandpaper to maintain control and precision.

Once the bulk of the old finish is gone, transition to a finer grit, like 120 or 150, to smooth the surface further. This stage is less about removal and more about refinement. The goal is to create a uniform texture that feels smooth to the touch, free of splinters or rough patches. Pay special attention to high-traffic areas, such as the edges of steps and handrails, where wear and tear are most evident. A consistent, even surface is crucial for the adhesion of new finishes, whether you’re staining, painting, or sealing the wood.

For the final pass, switch to an even finer grit, such as 220, to achieve a polished, professional finish. This step may seem tedious, but it’s the difference between a DIY project and a masterful renovation. Run your hand over the surface periodically to check for any remaining imperfections. If you’re planning to stain the wood, this smooth base will allow the color to penetrate evenly, enhancing the natural grain. If painting, it ensures a flawless, streak-free application.

Caution must be exercised throughout the sanding process. Dust from sanding wood can be hazardous if inhaled, so wear a mask and ensure proper ventilation. Additionally, avoid applying excessive pressure, as this can create uneven surfaces or damage the wood. For large staircases, consider using a power sander for the initial stages, but finish by hand to maintain control and precision. Finally, clean the surface thoroughly after sanding—use a tack cloth or damp rag to remove all dust particles before proceeding with your chosen finish. This meticulous preparation ensures that your staircase not only looks renewed but also stands the test of time.

Valuing Vintage Wooden Planes: Are They Worth Collecting Today?

You may want to see also

Explore related products

Apply New Finish: Stain, paint, or seal the staircase to enhance appearance and protect the wood

A fresh finish can transform an old wooden staircase, breathing new life into a well-worn structure. The choice of stain, paint, or sealant depends on the desired aesthetic and the level of protection needed. Stains penetrate the wood, enhancing its natural grain, while paints offer a uniform color and can hide imperfections. Sealants, on the other hand, provide a clear protective layer, preserving the wood’s original look. Each option requires specific preparation and application techniques to ensure durability and visual appeal.

Analytical Perspective: Staining is ideal for homeowners who want to maintain the wood’s character while adding warmth or depth. Water-based stains dry faster and emit fewer fumes, making them a safer choice for indoor projects. Oil-based stains, however, offer richer colors and deeper penetration but require longer drying times. For high-traffic staircases, consider a semi-transparent stain with a built-in sealant to combine aesthetics with protection. Always test the stain on a small area to ensure the color matches your vision.

Instructive Steps: Begin by sanding the staircase thoroughly to remove old finishes and smooth the surface. Use 80-grit sandpaper for initial stripping, followed by 120-grit for a finer finish. Clean the wood with a tack cloth to remove dust. Apply the stain or paint in thin, even coats using a brush or roller, working in the direction of the grain. Allow each coat to dry completely—typically 2–4 hours for water-based products and 8–12 hours for oil-based. For sealants, apply two coats with a brush, ensuring full coverage on edges and corners.

Comparative Insight: Paint offers the most dramatic transformation, especially for staircases with uneven surfaces or damage. It’s available in limitless colors and finishes, from matte to high-gloss. However, painted stairs may show wear more quickly, particularly on edges. Sealants are the most low-maintenance option, requiring reapplication every 2–3 years. They’re best for staircases in excellent condition where preserving the natural wood is the goal. Consider the long-term upkeep when deciding between these finishes.

Practical Tips: For a professional finish, use a paint sprayer for even coverage, especially on spindles and intricate details. If staining, apply a wood conditioner beforehand to ensure uniform absorption, particularly on softwoods like pine. Always ventilate the area during application and wear protective gear, including gloves and a mask. For added durability, mix a non-slip additive into the final coat of paint or sealant on stair treads to prevent accidents. Regularly inspect the finish and touch up as needed to maintain both appearance and protection.

Ruby Slipper Hydrangea: Blooming on New or Old Wood?

You may want to see also

Frequently asked questions

Start by removing any carpet, staples, or nails. Sand the surface thoroughly to remove old finish, stains, or rough patches. Clean the stairs and risers with a damp cloth to remove dust and debris before proceeding with repairs or refinishing.

Use wood filler or epoxy to repair cracks, holes, or splits in the stairs. For more extensive damage, replace individual treads or risers with matching wood species. Ensure all repairs are sanded smooth and level before refinishing.

Yes, you can change the color by staining or painting. Sand the stairs to bare wood, apply a wood conditioner if staining, and then use your chosen stain or paint. Seal with a protective finish like polyurethane for durability.

Install non-slip treads or adhesive strips for better traction. Add a sturdy handrail if one is missing or replace an old one. Ensure all steps are level and secure, and consider adding lighting for visibility.